Additional information to mercerisation of cotton and bast fibres

Back to Mercerisation of cotton and bast fibres

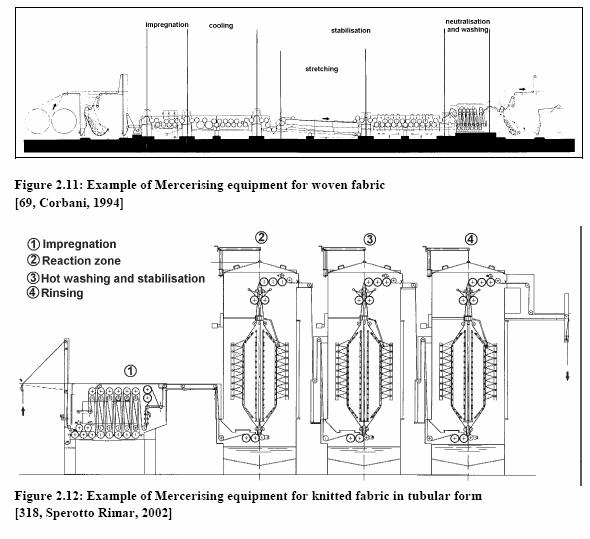

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

Mercerising is carried out in order to improve tensile strength, dimensional stability and lustre of cotton. Moreover an improvement in dye uptake is obtained (a reduction of 30 – 50% of dyestuff consumption can be achieved thanks to the increased level of exhaustion).

Mercerising can be carried out on yarn in hanks, woven and knitted fabric through one of the following different treatments:

- mercerising with tension

- caustification (without tension)

- ammonia mercerising

- Mercerising with tension

Caustic soda mercerising is the most commonly applied mercerising technique (it is not applied on flax). Cotton is treated under tension in a solution of concentrated caustic soda (270 – 300 g NaOH/l, which means also 170 – 350 g NaOH/kg) for approximately 40 – 50 seconds.

During mercerisation the temperature is adjusted at low values (5-18 °C) when the lustre is the priority and at slightly higher levels when the improvement of the other characteristics is preferred. Because the reaction between caustic soda and cellulose is exothermic, cooling system are applied to keep down the temperature of the bath.

Beside the conventional cold treatment, a hot mercerising process is also now increasingly applied (for hanks and fabric). The material is soaked in a solution of caustic soda close to boiling point. After hot stretching, the fabric is cooled down to ambient temperature and washed under tension.

In order to ensure a homogeneous penetration of the liquor, especially when operating at ambient temperature, wetting agents are employed. Sulphonates mixed with non-ionic surfactants and phosphoric esters are the most commonly used.

- Caustification

In the caustification process, the material is treated at 20 – 30 °C with caustic soda at lower concentration (145 – 190g/l) without applying tension. The material is allowed to shrink, thus improving the dye adsorption.

- Ammonia mercerising

Cotton yarn and fabric can be treated with anhydrous liquid ammonia as an alternative to caustic soda. Effects similar to mercerising are obtained, although the lustre gade is inferior to caustic soda mercerising. Traces of ammonia have to be removed, preferably with dry heat treatment followed by steaming.

This method is not widely used. Only a few plants are reported to use ammonia mercerising in Europe.

Literature: BAT – Best available Technologies in the Textile Industry, 2003

2. NEW TECHNOLOGIES

- a) Changes in the process

1) Development and Application of a practice for high-speed Mercerisation of Cotton

In previous experiments it was found that cotton, which was treated with low-pressure-oxygen-plasma, was able to absorb the mercerisation base much quicker (1 second). However, the physical-chemical reasons for this behaviour are unknown so far.

The aim of this project is to realise this high-speed mercerisation, thus saving time and shortening the base-zones in the mercerising-machines. Thereby, the plants can be scaled down, which normally are among the largest and most complex in textile finishing. Costs will be reduced. Within the framework of this project, the innovative plasma technology will be combined in an elegant way with Mercerisation, a process that has been practised for more than 100 years.

Perspectives

Based on the conclusions of this project, high-speed mercerisation shall be introduced in textile finishing. As a consequence, a clear reduction of water, energy and environmentally harmful chemicals can be achieved. a t i v e n N e t z w e r k e n For information on project partners, cooperation and for more details, click here.

Source:

Internet: InnoNet – Förderung von Innovativen Netzwerken: http://www.vdivde-it.de/innonet/projekte/textilien

- b) Changes in the heat supply system

No information is available.

- c) Changes in the energy distribution system

No information is available.