Biocides & plant health products

Back to Information about biocides and plant health products

1 Overview

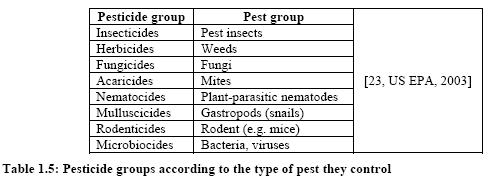

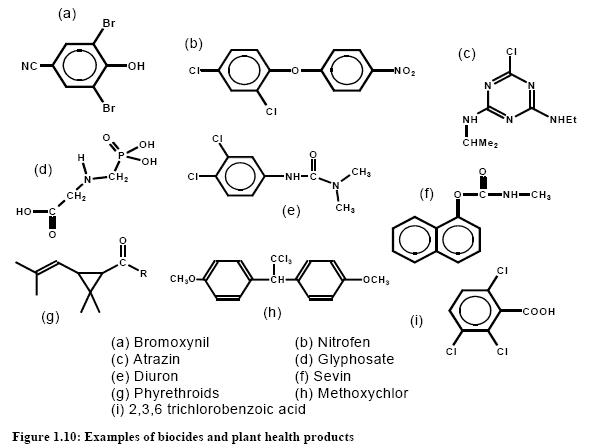

Biocides and plant health products are substances or mixtures of substances intended for preventing, destroying, repelling, or mitigating any pest. A more common term for these products is “pesticides”, which is taken to include herbicides and other groups as detailed below. Pests are living organisms that occur where they are not wanted or where they cause damage to crops or humans or other animals. Table 1.5 gives an overview of the types of biocides and plant health products according to the type of pest they control, and Figure 1.10 gives some examples of biocides and plant health products derived by chemical synthesis.

2 Production of Biocides and Health products

- Nitration

Liquid phase nitration is a dominant step in the manufacture of common high explosives and important for the production of a wide range of aromatic intermediates for dyes, agrochemicals, pharmaceuticals or other fine chemicals. A typical nitration reaction is higly exothermic, therefore, for a safe mode of reaction, a dosage controlled process with precautions securing no accumulation of reactants is necessary. Typical nitroaromatic production is based on high yield processes, with more than 80 % of the total cost being the cost of the raw materials. Integral requirements of all efficient nitration processes are sulphuric acid regeneration and isomer control and separation. Nitration of the important naphthalene mono- and disulphonic acids is usually performed with the formed sulphonated mass. Among the typical raw materials are halogenated aromatics, which can contribute to the AOX load of waste water streams.

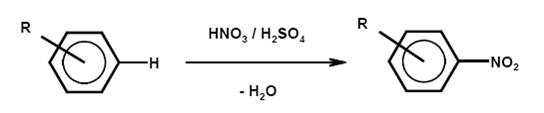

Chemical reaction

Nitration is the irreversible introduction of one or more nitro groups into an aromatic system by electrophilic substitution of a hydrogen atom. O-nitration to give nitrates and N-nitration to give nitramines are far less important for aromatic compounds but relevant for the manufacture of explosives.

Nitration is normally carried out in a liquid phase reaction with a mixture of nitric and sulphuric acids (mixed acid) and occasionally with nitric acid. A typical mixed acid, for example for mononitration, consists of 20 % nitric acid, 60 % sulphuric acid and 20 % water (this is referred to as 20/60/20 mixed acid). The strength of the mixed acid and the temperature can be varied to maximise the formation of the required isomer. Stronger mixed acid and higher temperature lead to oxidative side reactions. An important side reaction leads to phenolic by-products.

Operations

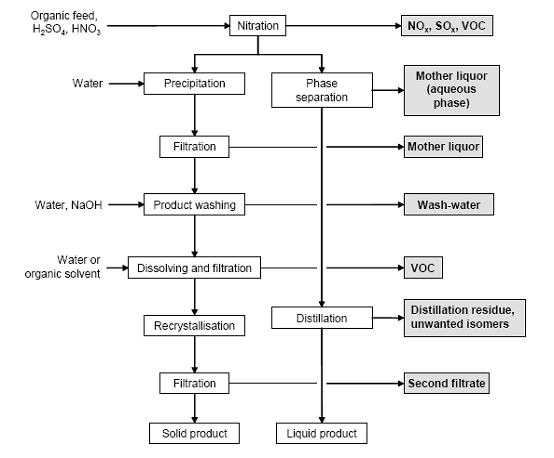

Figure 1 shows a typical sequence of operations for the nitration of aromatic compounds, possible input materials and associated waste streams. The reaction is carried out in cast iron, stainless steel or enamel-lined mild steel reactors. Temperatures vary normally between 25 and 100 °C. The substrate is dissolved in the sulphuric acid phase and the mixed acid is subsequently added. On completion of the reaction, the batch is transferred into water to give a two phase mixture of diluted acid and an organic product phase. After phase separation, liquid products are purified by distillation. The remaining acid phase can be extracted with the feed material in order to recover organic compounds. Solid products are crystallised (where necessary, by the addition of cold water). The crude nitroaromatic is washed with water and diluted NaOH to remove the acids and phenolic by-products. Depending on the quality requirements, a recrystallisation from water or organic solvent may be necessary. Isomer separation is carried out within the crystallisation, washing or distillation steps.

Figure 1: Typical sequence of operations for a nitration. Possible input materials (on the left) and the associated waste streams (grey background), BREF on Organic Fine Chemicals, Aug. 2006

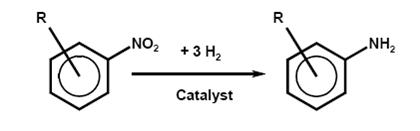

- Reduction of aromatic nitro compounds

One of the most industrially important reduction processes in industrial use is the conversion of an aromatic nitro or dinitro compound into an arylamine or arylene diamine. Aromatic amines are widely used as dye intermediates, especially for azo dyes, pigments, and optical brighteners; as intermediates for photographic chemicals, pharmaceuticals, and agricultural chemicals; in polymers via isocyanates for polyurethanes; and as antioxidants.

Among reduction methods, there are three of major relevance in organic fine chemistry:

- catalytic hydrogenation, which is extremely important industrially because of its universal applicability; most processes can be carried out successfully by catalytic hydrogenation

- Béchamp and Brinmeyr reduction with iron, which is the classical method

- alkali sulphide reduction, which is the selective method in specific cases, such as in the manufacture of nitroamines from dinitro compounds, the reduction of nitrophenols, the reduction of nitroanthraquinones and the manufacture of aminoazo compounds from the corresponding nitroazo derivative.

All three methods are also applied to halogenated nitro compounds, and can thus contribute to AOX loads in waste water streams.

- a) Catalytic reduction with hydrogen

Chemical reaction

The catalytic reduction of the nitro compounds is very exothermic. To reduce these hazards, the concentration of nitro compound, the amount and partial pressure of the hydrogen, the temperature, and the activity of the catalyst, are controlled.

Most aromatic nitro compounds are hydrogenated in the liquid phase. In this case, the pressure and temperature can be changed independently. The temperature is limited by the hydrogenation reaction of the aromatic ring which occurs above 170–200°C.

Normally, the reduction is carried out at 100–170°C. Sensitive compounds are hydrogenated at lower temperatures (20–70°C) or at lower pressures (1–50 bar). 1–50 bar are used normally.

The preferred solvents are methanol and 2-propanol; and also dioxane, tetrahydrofuran, and N-methylpyrrolidone are used. In the hydrogenation with a water immiscible solvent, such as toluene, the water must be removed, as in solvent-free hydrogenation, in order to maintain the activity of the catalyst. If the amine has a good water solubility, water is used as the solvent. Water also can be used in cases where the nitro compound forms water-soluble salts with alkalis, such as with nitrocarbonic or sulphonic acids. In practice, only Raney nickel, Raney nickel-iron, Raney cobalt, and Raney copper are used as pure metal catalysts because of their relatively low cost. Precious metal catalysts, such as Pt and Pd, are generally used at concentrations of 0.5 – 5 wt-% on support material with large surfaces, such as charcoal, silica, aluminium oxide, or alkaline-earth carbonates.

Process hazards

The catalytic reduction of nitro compounds is very exothermic. Unless this heat is dissipated properly, decomposition and even explosions can result, especially if the thermal decomposition of the nitro compound occurs or if condensation reactions are initiated as may be the case with chloro-nitro compounds. The industrial hydrogenation of aromatic polynitro compounds in the liquid phase without solvents especially requires precautions. To reduce these hazards, the concentration of the nitro compound, the amount and partial pressure of the hydrogen, the temperature, and the activity of the catalyst are controlled. The nitro compound is continuously added in small quantities, thus keeping its concentration below 2 %. De-ionised water is added to remove the heat of the reaction by continuous evaporation and to slow down the activity of the catalyst.

Operations

The vast majority of aromatic amines have small annual volumes (<500 tonnes) and are produced by batch hydrogenation with catalyst slurries. The reaction is carried out in stirred, steel or stainless steel autoclaves or in loop reactors. Loop reactors show increased heat and mass transfers and improved reaction selectivity, shorter batch cycle times and higher product yields. In addition, catalyst usage is often lower. The addition sequence depends on the particular reactants. On completion the reaction mass is cooled and the catalyst is removed by filtration.

- b) Reduction with iron

Chemical reaction

The reduction of nitroaromatics is carried out in the presence of small amounts of acid (HCl, H2SO4, HCOOH, CH3COOH) as shown in the following equation:

4 Ar – NO2 + 9 Fe + 4 H2O 4 Ar – NH2 + 3 Fe3O4

The acid is used for the activation of the iron. Only 2 – 3 % of the hydrogen is derived from the acid but 97 – 98 % comes from the water.

Operations

Normally the nitroaromatic is added to the mixture of iron/water/acid (excess of iron about 15-50 %) often in the presence of an organic solvent (toluene, xylol, alcohols) and the mixture is heated to reflux. Depending on the reactivity of the aromatic, other addition sequences may be required. In some cases the acid is omitted (neutral iron reduction). The build-up of unreduced excess nitro compound must be avoided and the final mixture should be tested for its total absence. After basification with soda ash (anhydrous sodium carbonate) to precipitate soluble iron, the iron compounds are removed by filtration.

- c) Alkali sulphide reduction

Chemical reaction

The alkali sulphide reduction is a mild and selective reaction according to the following equation, without strict stoichiometry:

Ar – NO2 + Na2S2 + H2O Ar – NH2 + Na2S2O3

Other reducing agents in use are Na2S or NaSH, which also form Na2S2O3. Sulphur may be added to reduce the required amount of sulphide.

Operations

Dilute aqueous sulphide is added to the solution or emulsion of the nitro compound. Temperatures (in the range of 80–100°C) and concentrations depend on the reactivity of the nitroaromatic. An excess of sulphide is avoided in the case of the selective reduction of polynitro compounds.

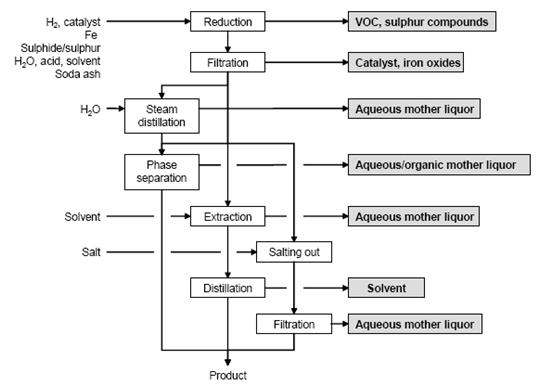

PRODUCT WORK-UP:

Figure 2 shows a typical sequence of operations for the reduction of aromatic nitro compounds, possible input materials and associated waste streams. The work-up depends on the properties of the amine obtained. Common methods are:

- separation as a liquid

- cooling and salting out

- steam distillation

- extraction with organic solvent, and

- pH adjustment if necessary.

3 Process modifications in manufacturing crop protection agents

Depending on the country requirements, usually the manufacturing route, description of the starting materials and a specification have to be explained. A modification, which may result in a change to the technical specification, can require some additional studies. For example, changes in the purity of an active ingredient may modify its toxicological or ecotoxicological profile or its ability to be formulated into a plant protection product. The crop protection manufacturing process is subject to specific regulations for any changes to the once approved process via the submission of a “5-batch analysis”. This has to show that the proposed change does not affect the minimum purity of the active ingredient or the maximum levels of any other impurities or lead to the presence of any new impurities.

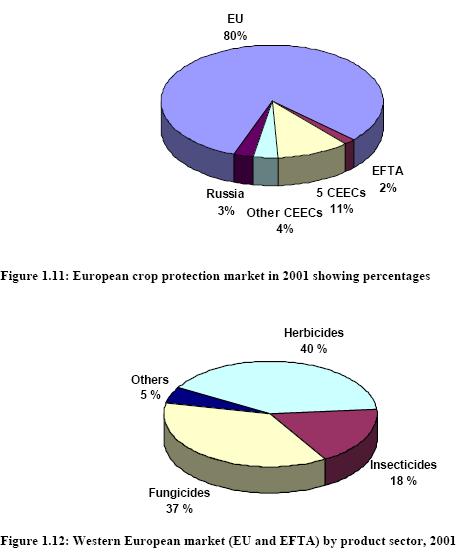

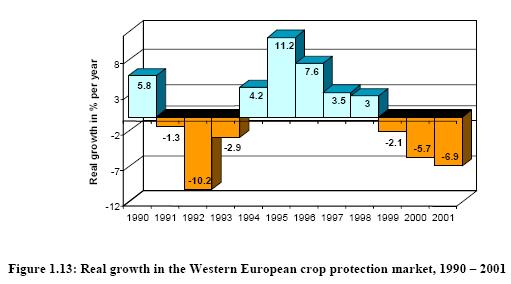

4 Economics of crop protection

Not all biocides and plant health products are used for crop protection but only the following information has been submitted. Over the past ten years, the European crop protection market has been affected by highly volatile economic and political conditions. Despite the pressure that the agricultural sector has been subjected to, the market for crop protection products in the EU continues to be the second largest in the world after North America. Figure 1.12 and Figure 1.13 give an overview of the market composition and development in Europe.

Over the past ten years, the relatively poor performance of the global market (see Figure 1.13) has resulted in considerable consolidation, with a number of companies leaving the market. From a European perspective, the most significant moves have been the merger of Zeneca and Novartis to form Syngenta, the acquisition of Cyanamid by BASF, and the purchase of Aventis by Bayer (so bringing the former operations of Rhone-Poulenc, Hoechst, Schering, Boots and Fisons into one company). Six companies now dominate the global market, with three of these (Syngenta, BASF and Bayer) based in Europe. The other three US companies (Monsanto, Dow and Dupont) all have significant subsidiaries in the EU.

Literature: BAT for the Manufacture of Organic Fine Chemicals, August 2006

Back to Information about biocides and plant health products