Canned fish/shellfish products

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about fish aroma

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of the production line

No information is available.

- 2. Description of techniques, methods and equipment

- (BAT in the Food, Drink and Milk Industries, June 2005)

Raw fish are washed, cut into fillets and then steamed in cooking/cooling tunnels. After head removal, white fish are filleted in machines with two sets of rotating knives that cut the fillets from the bone and cut off the collar bones. The knives are watered to cool them and to clean off fish meat and scale. Next, the two fillets are conveyed skin-side down to the skinning phase. Fatty fish are orientated in a forward direction and held into position, using water jets, until aligned with a stop plate. They are de-headed and the tails and guts are taken out before entering the filleting machine. The two fillets then proceed to the skinning stage. Filleting and skinning may be carried out manually. Descaling is sometimes achieved using caustic baths. Fish off-cuts are normally transported to the waste collection area via chutes, water flumes or conveyor belts. After steaming, the fish are filled into cans, which contain either brine, oil or sauce. The cans are sealed by passage through a can seamer. Precooking, skinning and cutting are carried out if medium size or large fish are processed. Small fish are put in cans whole and are cooked directly in the can. After seaming, the cans pass into a retort for sterilisation. Here, the product is heated at a sufficient temperature to inactivate any food poisoning micro-organisms. The product is then cooled with chlorinated water. Shellfish are processed in a similar manner but are often transported under a rocking motion through a scalding system to open the shells and dislodge the flesh. Additional washing and trimming steps may also be incorporated to remove sand and mud. The curing and smoking of fish and during processing of shellfish, may also be carried out.

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data

- (BAT in the Food, Drink and Milk Industries, June 2005)

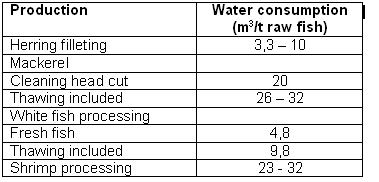

To meet quality and hygiene standards, the fish sector used high quantities of water. It is mainly consumed for cleaning operations and washing, and transportation of fish. Fish canning and fish filleting consume large quantities of water, e.g. to clean and lubricate the filleting machinery. Typical figures for fresh water consumption are for thawing, about 1 m3/t fish; for filleting 5-11 m3/t fish, and for canning, 15 m3/t fish. Water is used for transporting fish and viscera, for cleaning the installation and the equipment, for washing raw materials and products, and for thawing. The following table shows the specific water consumption for traditional fish processing:

Table 1: Specific water consumption in Nordic countires

The consumption of energy depends on the installation, the equipment and the fish manufacturing processes that take place. Processes, e.g. canning, that involve heating, cooling, production of ice, drying, evaporation and oil production consume more energy than those that do not, e.g. filleting, where energy consumption is low. On average, filleting consumes 65-87 kWh/t of fish and canning consumes 150-190 kWh/t of fish.

2. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about fish aroma