Difference between revisions of "Carbonizing in textile industry"

m (Protected "Carbonizing in textile industry" [edit=autoconfirmed:move=autoconfirmed]) |

m (Changed protection level for "Carbonizing in textile industry" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

(No difference)

| |

Latest revision as of 11:00, 1 March 2013

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

1. OBJECTIVE

Sometimes scoured wool contains vegetable impurities that cannot be completely removed through mechanical operations. Sulphuric acid is the chemical substance used for destroying these vegetable particles and the process is called carbonizing (BAT for the Textiles Industry, July 2003).

2. FIELD OF APPLICATION

Carbonizing can be carried out on (BAT for the Textiles Industry, July 2003):

- floc/loose fibre

- fabric

This operation is not applied in the carpet sector.

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Loose fibre carbonizing: (BAT for the Textiles Industry, July 2003)

It is performed only on fibres that are later used to produce fine fabric for garments (worsted fabrics) and usually takes place at the scouring mill.

In typical equipment for carbonisation of loose fibre, the still damp scoured wool is soaked in a solution containing 6 – 9 % of mineral acid (generally sulphuric acid). Excess acid and water are removed by pressing or by centrifugation until on average 5 – 7.5 % of sulphuric acid and 50 – 65 % of water remain. The fibres are then dried at 65 – 90 ºC to concentrate the acid and baked at 105 – 130 ºC (CSIRO method) (literature: IPPC- BAT). Dry and bake in the dryer at 140° (literature: H.K. Rouette: Encyclopedia on textile finishing, Springer, 2001)

As soon as the wool is dried, it is fed into a machine, which consists of two counter-rotating rolls. These rolls crush the carbonised particles into very small fragments, which are then easily removed. The addition of small quantities of detergent to the sulphuric acid improves the yield and reduces the attack on the wool. In order to prevent the fibre from being gradually degraded, the pH is finally set to 6 by neutralisation (bath) with sodium acetate or ammonia.

Sulphuric acid can be replaced by gaseous HCl or by aluminium chloride.

After carbonizing, the fibre can be carded and then spun before being dyed or it can be dyed directly in floc form.

- Fabric carbonizing: (BAT for the Textiles Industry, July 2003)

It is typical of woollen fabrics. The operation can be carried out by either the traditional or the more modern "Carbosol" system.

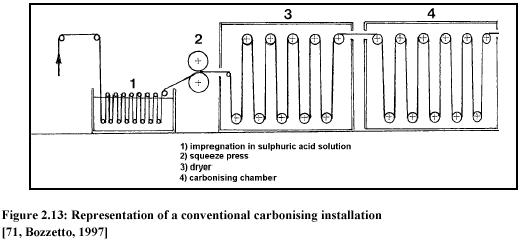

The conventional procedure is substantially similar to that used for loose fibre. The fabric can be previously soaked in a water or solvent bath and squeezed, but this step is optional. Then it is impregnated in a concentrated sulphuric acid solution (acidification) and squeezed (hydro-extraction) before passing through the carbonizing chamber. The carbonised particles are then removed by mechanical action and subsequent washing. In modern carbonizing plants all these steps are carried out in continuous mode.

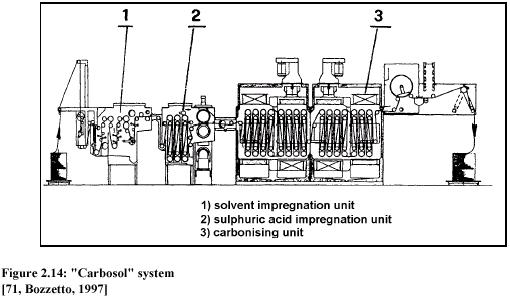

The "Carbosol" process, licensed by SPEROTTO RIMAR, uses an organic solvent instead of water. The equipment consists of three units. In the first one the fabric is impregnated and scoured with perchloroethylene, in the second the material is soaked in the sulphuric acid solution and in the third, carbonizing and solvent evaporation take place. At this stage the perchloroethylene is recovered by distillation in a closed loop.

The “Carbosol” system is reported to have several technical advantages over the traditional process. The level of acidity of the fabric after carbonizing is much lower and the risk of damage to the wool fibre is reduced. Thanks to full recovery of the organic solvent, the process can also be considered more efficient from the environmental point of view.

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.