|

|

| Line 1: |

Line 1: |

| | {| class="wikitable" | | {| class="wikitable" |

| − | |Different process technologies exist within industry, which lead to several possibilities for the integration of solar heat. Based on the general classification of industrial heat consumers cleaning processes are assigned either to the category “(pre)heating of fluid streams” or “heating and maintaining temperature of baths, machineries or tanks”. By consideration of the conventional heat supply, different integration concepts are possible. | + | !colspan="6"|Different process technologies exist within industry, which lead to several possibilities for the integration of solar heat. Based on the general classification of industrial heat consumers cleaning processes are assigned either to the category “(pre)heating of fluid streams” or “heating and maintaining temperature of baths, machineries or tanks”. By consideration of the conventional heat supply, different integration concepts are possible. |

| | |- | | |- |

| | |[[File:PL_E_PM.jpg]] | | |[[File:PL_E_PM.jpg]] |

| Different process technologies exist within industry, which lead to several possibilities for the integration of solar heat. Based on the general classification of industrial heat consumers cleaning processes are assigned either to the category “(pre)heating of fluid streams” or “heating and maintaining temperature of baths, machineries or tanks”. By consideration of the conventional heat supply, different integration concepts are possible.

|

|

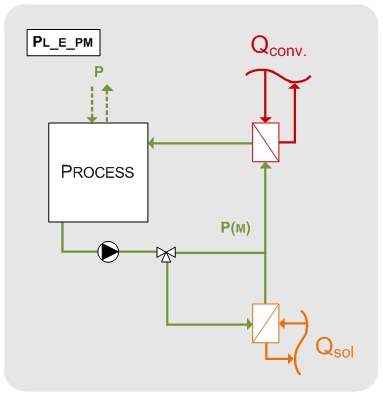

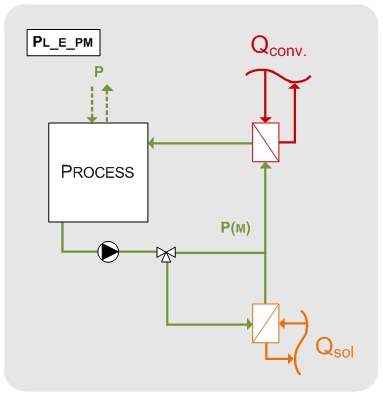

PL_E_PM - external HEX for heating of product or process medium

This integration concept is basically the easiest since an additional solar driven heat exchanger is installed in serial to the conventional heat exchanger to heat a product or process medium (e.g. water, lye, fruit juice, etc.). It can be applied to all three categories of heat consumers “(pre)heating of fluid streams”, “heating and maintaining temperature of baths, machineries or tanks” and “thermal separation processes”. The serial integration of a solar driven heat exchanger can be realized in a way that only part of the entire product or process medium stream is heated up and hence heat exchanger surface, pump and pipe dimensions can be kept small.

|

|

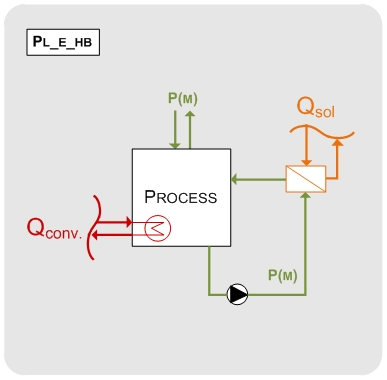

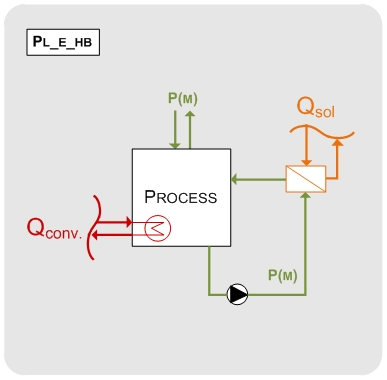

PL_E_HB - external HEX for heating of bath, machinery, or tank

This integration concept is used to heat baths, machineries, or tanks via an additional external heat exchanger. Therefore, the product or process medium is drawn from the bath, machinery, or tank, heated by solar energy and fed back. It’s crucial for this integration concept to identify a suitable position or point in time within the process where the temperature of the product or process medium is relatively low. Else this concept would lead to a parallel integration of solar heat to the conventional heat supply. If the product or process medium must be kept in a very narrow temperature range (due to operational issues), the resulting temperature difference for solar heating might be very small.

|