Drying in Emerging technologies

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Emerging Technologies in Drying

- 1. Concentration of product

Thermal concentration The concentration of liquid product streams is primarily intended to reduce the cost of storing, packaging, handling and transport by the reduction of the volume . Furthermore, the concentration promotes durability because water contributes significantly as a main component of liquid foods for growth of microorganisms. The reduction of the water content by concentration thus results in a reduction of the microbial load and enhances the durability of the product.

Typical products which are concentrated in the food industry are fruit juices, jams and marmalades, milk for the production of condensed milk, whey and lactose as a precursor to dry, sugar syrup, malt and glucose syrup, vegetable juices, purees and pastes. In dry countries , drinking water is generated by the evaporation of sea water , the concentrated salt solution and the remaining salt is a by-product . The conventional evaporation method used for concentrating foods includes batch and Beck evaporators, natural circulation evaporator (Robert evaporator, Vogelbusch evaporator), forced circulation evaporator, rising or falling film evaporator, thin film evaporator, plate evaporator, flash evaporator, but also the concentration by freezing is possible. To increase the energy efficiency of conventional evaporator which is formed during the evaporation vapors (vapor-saturated air) can be directly used (in uncompressed form) in the next stages of a multistage evaporation as a heating medium again . The vapors can be condensed by mechanically or thermal process, before they are used in the subsequent or the same evaporation stage again.

Conventional Concentration of Whey

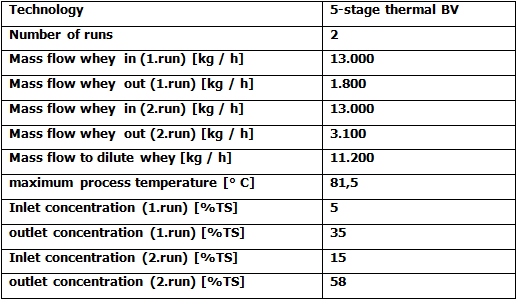

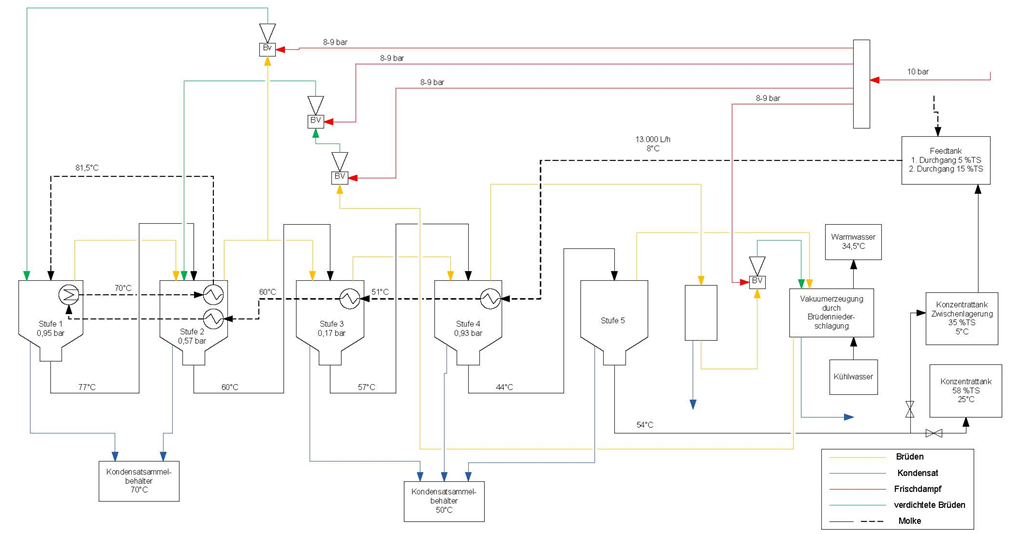

The resulting sweet whey from cheese production is a concentrated by evaporation and then spray dried and fed to the whey powder production. The whey is evaporated to a solids concentration of 58%. Before the evaporation process , fat and cheese dust (or pieces of cheese) are removed using a Seperator from the whey. The evaporation and concentration of whey is done in a five-step thermal vapor compressor (BV). The whey comes with a solids concentration of 5% in the first stage of evaporation. The feed is first preheated by heat exchanger in all evaporator stages to 81.5 ° C. The mass flow rate at the evaporator inlet is 13,000 kg / h. The whey contains after the first round of the five-stage BVs a solids concentration of 35% and goes out of 1,800 kg / h from the evaporator. This concentrate is stored in a concentrate tank and cooled to 5 ° C.

The 35% concentrate is diluted with fresh whey (5% TS) to a concentration of 15%. Then the 15% whey goes through a mass flow rate of 13,000 kg / h evaporation plant again and is concentrated to a solid concentration of 58%. The mass flow of 58% concentrate is 3100 kg / h. The concentrate passes after the final evaporation stage of the second pass in a tank and the concentrate is cooled to 25 ° C. From the concentrate tank, the whey concentrate then passes on to the next process step, the drying. Drying takes place in a spray drier and the final product is whey with a solids concentration of 97.5 to 98.5%. This powder is sold at 0.7-0.8 € / kg and used as a feed additive or food for cheese or baked goods.

- Figure 1 Simplified flow diagram of the five-stage is in BVs

- Figure 2 Simplified flow diagram of the 5-stage BVs for the concentration of whey

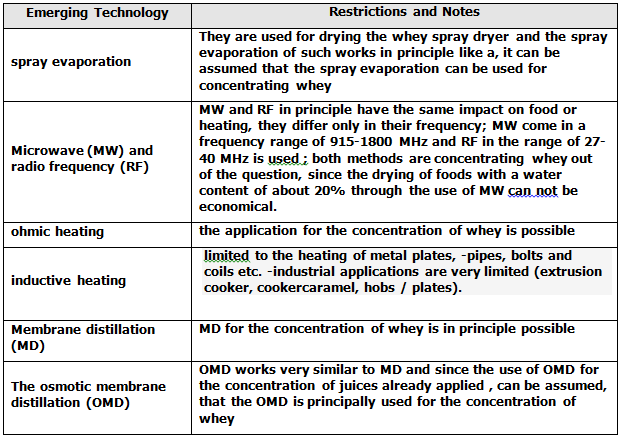

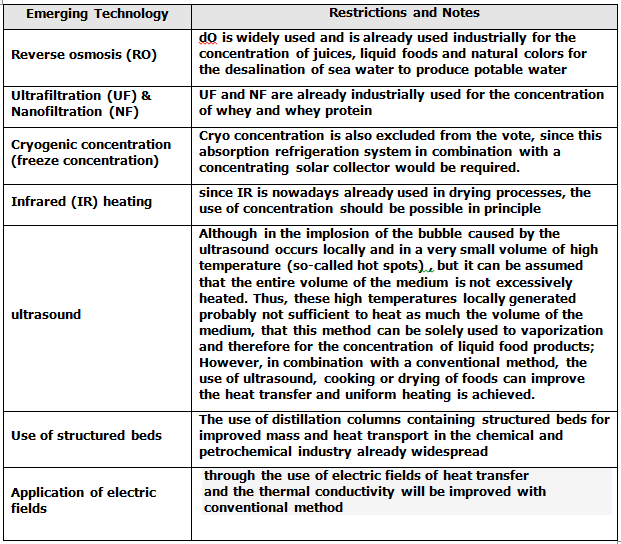

- 2.Potential ET for the concentration

The table below shows the list of identified ET for the concentration of food.

- Table 1 List of Identified ET for concentration of food

- 3. New Technologies

- A)Membrane Distillation

- General Description

The MD is a thermal process in which molecules can diffuse through only vapor through a porous hydrophobic membrane. The liquid feed is in direct contact with one side of the membrane but prevent the penetration of the hydrophobic properties of the liquid into the pores of the membrane by the prevailing surface tension (interfacial tension). This results in the liquid-vapor phase boundary surfaces of the openings of the membrane pores. The driving force of the MD is a vapor pressure differential between the feed side and the permeate side of the membrane. There different types by which this difference can be achieved.

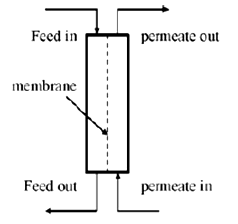

- Direct contact membrane distillation (DKMD)

When DKMD flowing on the permeate side of the membrane in direct contact with an aqueous solution having a lower temperature than the feed, in the opposite direction of the feed flow direction. Due to the difference in temperature of the feed and the permeate there is a vapor pressure difference, start by which volatile molecules of the warmer feeds to evaporate and thus can penetrate the membrane in the vapor state. The vapor then condenses on the colder liquid-vapor phase boundary on the permeate side of the membrane again.. The disadvantage of the DKMD is that this configuration has the highest MD heat losses by thermal conduction of the membrane. An essential advantage lies in the DKMD the ease of use when compared with the other configurations.

- Figure 3 Direct-Contact-membrane distillation (DKMD)

- Process model and technology analysis MD

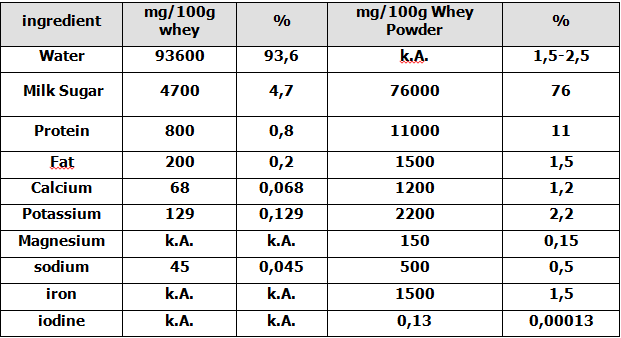

In order to select a suitable membrane for the MD, it is first important to know the components of the feed.

- Table 2 List of The ingredients of whey in mg per 100 g of liquid and powdered whey

The three main components of the liquid whey are carbohydrates (in the form of lactose), proteins (in the form of whey protein), and fat. Since the whey is degreased before concentration , the majority of the fat falls off as an essential component and does not need to be taken into account in the further specific membrane selection. The whey protein, which consists of albumins and globulins, according to is the "highest quality protein of nature" and is unmatched by any other known protein in its quality exceeded In industry, it is often the case that the proteins in the whey for example by Ultrafiltration (UF) are separated from the remaining components as a pure and concentrated protein concentrate . These whey proteins are valuable food additives and (protein shakes for athletes) are used including in baby food or diet and sports drinks.

- Energy consumption MD

The use of the MD in the industry can be assumed that a plurality of MD modules are connected in series to achieve the desired solids concentration and the feed is not recycled. Furthermore, a series connection of modules is useful in order to achieve the required by the industry flow rate per unit of time can.

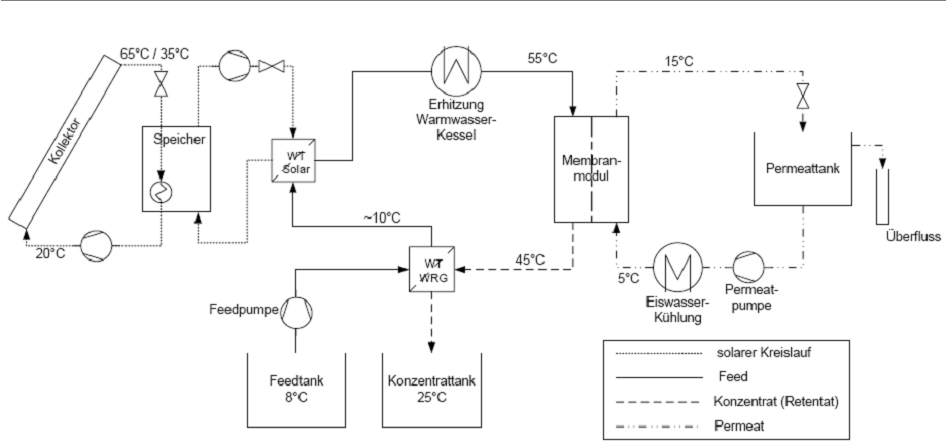

- Figure 4 Flow diagram MD for the concentration of whey including solar thermal integration - a variant (WRG between feed and concentrate)

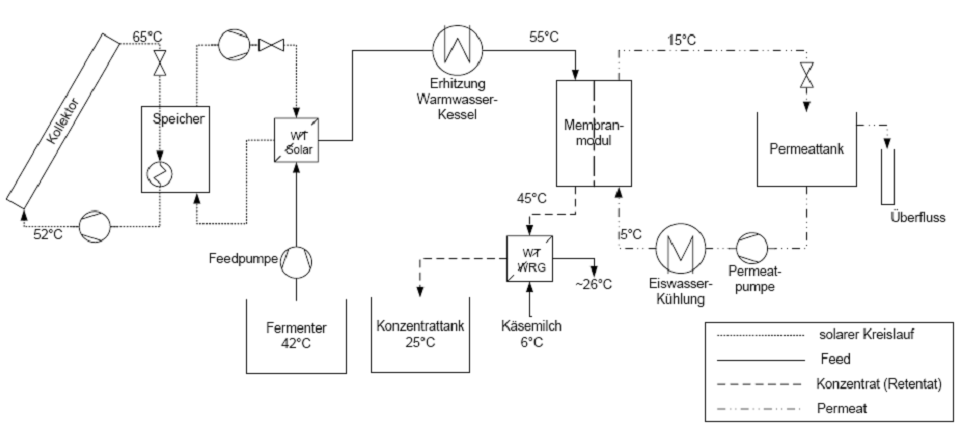

- Figure 5 Flow diagram MD for the concentration of whey including solar thermal integration - c variant (use straight from the fermenter)