Difference between revisions of "Drying in chocolate, cacao & coffee production"

From Efficiency Finder

(Created page with "BACK to *EFFICENCY FINDER OF FOOD INDUSTRY *Information about chocolate, cacao & coffee production '''I. DESCRIPTION OF TECHNIQUES, METHODS AN...") |

|||

| Line 1: | Line 1: | ||

| − | BACK to | + | BACK to |

*[[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | *[[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | ||

*[[Information about chocolate, cacao & coffee production]] | *[[Information about chocolate, cacao & coffee production]] | ||

| − | |||

| − | |||

| − | + | '''1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT''' | |

| − | + | *Description of the process of drying in decaffeinated coffee production (Ullmann's Encyclopedia of Industrial Chemistry, Vol.A7, 1994) | |

| + | :In the decaffeinated coffee production drying is applied in both low-moisture and high-moisture technologies. Drying in both cases is accomplished using heat, while the temperature rates of drying in both cases are 40-80°C and the residence time 0.5-10h. | ||

| − | |||

| − | |||

| − | + | *Description of the process of drying in instant coffee production (Ullmann's Encyclopedia of Industrial Chemistry, Vol.A7, 1994) | |

| − | + | ||

| − | + | :There are two different ways of drying instant coffee: | |

| − | |||

| − | |||

| − | |||

| − | ; | + | :;a) Spray-drying |

| − | + | ||

| − | + | ::Cooled and clarified extract is nebulized through a rotary or static pressure nozzle into the top of a spray tower, dried by a cocurrent flow of hot air at ca. 205°C, and collected in the conical bottom of the tower at a temperature ca. 50°C. In this way, free-flowing nondusty powders with a mean size of 200-300μm and a residual moisture of 2-4% are obtained. Bulk density can be adjusted between 230-280g/L by foaming the extract with an inert gas, usually carbon dioxide or nitrogen. The powder can be agglomerated to a coarse structure by rewetting, which makes it easy to spoon and mix with hot water. | |

| − | + | ||

| − | + | ::[[File:Spray-dryer tower.jpg]] | |

| − | + | ||

| − | + | ::Figure 1: Spray-drying tower. | |

| − | + | ||

| − | + | ::a) Cooled and clarified coffee extract (30-50% solids); b)Nozzle assembly; c)Hot air (c.a. 250°C); d)Transition cone for uniform spray-air mixing flow in the upper region of the dryer; e)Exhaust air to dry collector for the fines recovery by cyclone or bag filter (reslurried in the feed or agglomerated); f)Chamber cone; g)Powder discharge (over 90% recovery) | |

| − | + | ||

| + | ::LITERATURE: Ullmann’s Encyclopedia of Industrial Chemistry, 1994, Vol. 7 | ||

| − | |||

| − | ; | + | :;b) Freeze-drying |

| − | + | ||

| − | + | ::During this operation, extract is frozen with separation of ice crystals, which are then sublimated under vacuum. The process entails several steps: | |

| − | + | ||

| − | + | ::• Primary freezing: Cold extract at 4-5°C is prechilled to soft ice slush at -6 to -8°C. The bulk density and, to some extent, the colour of the final product depend on the degree and nature of foaming, with nitrogen giving a lighter product than carbon dioxide. | |

| − | + | ||

| + | ::• Secondary freezing: The soft ice is cooled down stepwise to -40 to -50°C on a steel belt, on trays or on drums. The colour and aroma retention of the product are influenced by the size and the rate of formation of ice crystals. Larger crystals give a darker product, with freezing times of 10-180min, while light-coloured products can be obtained by fast freezing for 30-120s in freezing drums. | ||

| − | BACK to | + | ::• Grinding: The ice slabs at a temperature of -40 to -45°C are ground and sieved to the desired size. Undesired or fine particles are reworked. The frozen particulate is put into trays, which are loaded on carriers and introduced into the drying section. |

| + | |||

| + | ::• Drying: The drying chamber may be a batch type, where the trays remain fixed on heating plates through the drying operation, or a semi-continuous type, in which the tray carriers move through a vacuum lock into a drying tunnel, where they pass through successive temperature zones and exit through another vacuum lock. In a fully continuous freeze dryer, the frozen coffee particulate is fed directly into the vacuum chamber from a feed tank, progressing through the dryer to a discharge tank. The drying chamber is fitted with heating plates, which provide the sublimation energy to convert ice into water vapor. The vapor is collected on cooled condensers and a pumping device keeps the chamber pressure lower than the triple point of water (6130bar). A product with 1-4% moisture at a temperature of 45-50°C is obtained. | ||

| + | |||

| + | |||

| + | |||

| + | '''2. NEW TECHNOLOGIES''' | ||

| + | |||

| + | :;a) Changes in the process | ||

| + | |||

| + | ::No information is available. | ||

| + | |||

| + | :;b) Changes in the energy distribution system | ||

| + | |||

| + | ::No information is available. | ||

| + | |||

| + | :;c) Changes in the heat supply system | ||

| + | |||

| + | ::No information is available. | ||

| + | |||

| + | <br/>BACK to | ||

*[[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | *[[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | ||

*[[Information about chocolate, cacao & coffee production]] | *[[Information about chocolate, cacao & coffee production]] | ||

Latest revision as of 13:15, 30 August 2013

BACK to

1. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Description of the process of drying in decaffeinated coffee production (Ullmann's Encyclopedia of Industrial Chemistry, Vol.A7, 1994)

- In the decaffeinated coffee production drying is applied in both low-moisture and high-moisture technologies. Drying in both cases is accomplished using heat, while the temperature rates of drying in both cases are 40-80°C and the residence time 0.5-10h.

- Description of the process of drying in instant coffee production (Ullmann's Encyclopedia of Industrial Chemistry, Vol.A7, 1994)

- There are two different ways of drying instant coffee:

- a) Spray-drying

- Cooled and clarified extract is nebulized through a rotary or static pressure nozzle into the top of a spray tower, dried by a cocurrent flow of hot air at ca. 205°C, and collected in the conical bottom of the tower at a temperature ca. 50°C. In this way, free-flowing nondusty powders with a mean size of 200-300μm and a residual moisture of 2-4% are obtained. Bulk density can be adjusted between 230-280g/L by foaming the extract with an inert gas, usually carbon dioxide or nitrogen. The powder can be agglomerated to a coarse structure by rewetting, which makes it easy to spoon and mix with hot water.

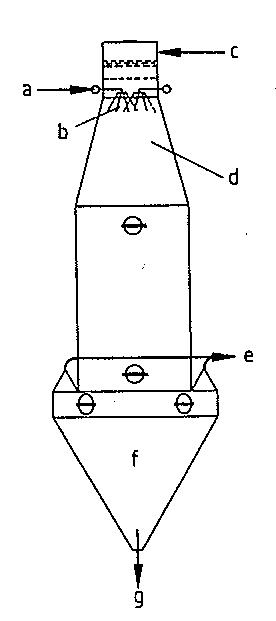

- Figure 1: Spray-drying tower.

- a) Cooled and clarified coffee extract (30-50% solids); b)Nozzle assembly; c)Hot air (c.a. 250°C); d)Transition cone for uniform spray-air mixing flow in the upper region of the dryer; e)Exhaust air to dry collector for the fines recovery by cyclone or bag filter (reslurried in the feed or agglomerated); f)Chamber cone; g)Powder discharge (over 90% recovery)

- LITERATURE: Ullmann’s Encyclopedia of Industrial Chemistry, 1994, Vol. 7

- b) Freeze-drying

- During this operation, extract is frozen with separation of ice crystals, which are then sublimated under vacuum. The process entails several steps:

- • Primary freezing: Cold extract at 4-5°C is prechilled to soft ice slush at -6 to -8°C. The bulk density and, to some extent, the colour of the final product depend on the degree and nature of foaming, with nitrogen giving a lighter product than carbon dioxide.

- • Secondary freezing: The soft ice is cooled down stepwise to -40 to -50°C on a steel belt, on trays or on drums. The colour and aroma retention of the product are influenced by the size and the rate of formation of ice crystals. Larger crystals give a darker product, with freezing times of 10-180min, while light-coloured products can be obtained by fast freezing for 30-120s in freezing drums.

- • Grinding: The ice slabs at a temperature of -40 to -45°C are ground and sieved to the desired size. Undesired or fine particles are reworked. The frozen particulate is put into trays, which are loaded on carriers and introduced into the drying section.

- • Drying: The drying chamber may be a batch type, where the trays remain fixed on heating plates through the drying operation, or a semi-continuous type, in which the tray carriers move through a vacuum lock into a drying tunnel, where they pass through successive temperature zones and exit through another vacuum lock. In a fully continuous freeze dryer, the frozen coffee particulate is fed directly into the vacuum chamber from a feed tank, progressing through the dryer to a discharge tank. The drying chamber is fitted with heating plates, which provide the sublimation energy to convert ice into water vapor. The vapor is collected on cooled condensers and a pumping device keeps the chamber pressure lower than the triple point of water (6130bar). A product with 1-4% moisture at a temperature of 45-50°C is obtained.

2. NEW TECHNOLOGIES

- a) Changes in the process

- No information is available.

- b) Changes in the energy distribution system

- No information is available.

- c) Changes in the heat supply system

- No information is available.

BACK to