Difference between revisions of "Dyeing of cotton and bast fibres"

From Efficiency Finder

(New page: Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY *;Additional information *;Typical dyeing process...) |

m (Changed protection level for "Dyeing of cotton and bast fibres" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

| − | *;[[Additional information: Dyeing of | + | *;[[Additional information: Dyeing of cllulose fibres|Additional information]] |

| Line 62: | Line 62: | ||

| style="background:#AACCEE;"| Cotton yarn|| align="center"| dyeing|| align="center"| 0,8-1,1|| align="center"| 13-16|| align="center"| 15-30|| align="center"| 60|| align="center"| reactive dyes | | style="background:#AACCEE;"| Cotton yarn|| align="center"| dyeing|| align="center"| 0,8-1,1|| align="center"| 13-16|| align="center"| 15-30|| align="center"| 60|| align="center"| reactive dyes | ||

|- | |- | ||

| − | | style="background:#AACCEE;"| Cotton yarn|| align="center"| dyeing|| align="center"| 0,8-1,1|| align="center"| 13-16|| align="center"| 100- | + | | style="background:#AACCEE;"| Cotton yarn|| align="center"| dyeing|| align="center"| 0,8-1,1|| align="center"| 13-16|| align="center"| 100-150°|||| align="center"| sulphuric dyes |

|} | |} | ||

| − | + | °total water consumption | |

Back to [[Subsection DB textiles|EFFICIENCY FINDER FOR TEXTILE INDUSTRY]] | Back to [[Subsection DB textiles|EFFICIENCY FINDER FOR TEXTILE INDUSTRY]] | ||

Latest revision as of 12:28, 1 March 2013

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

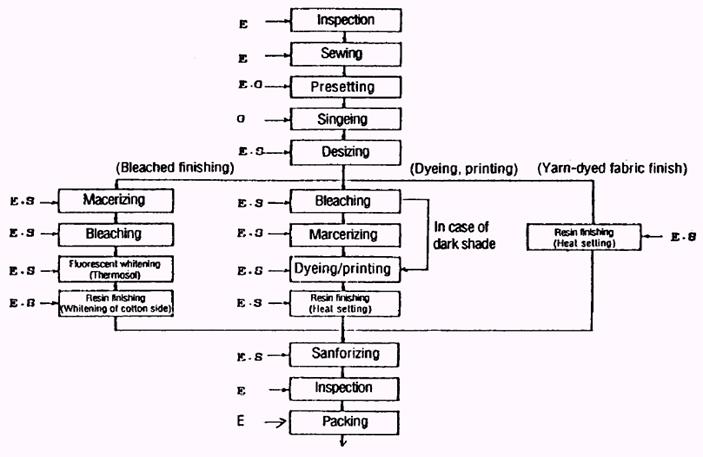

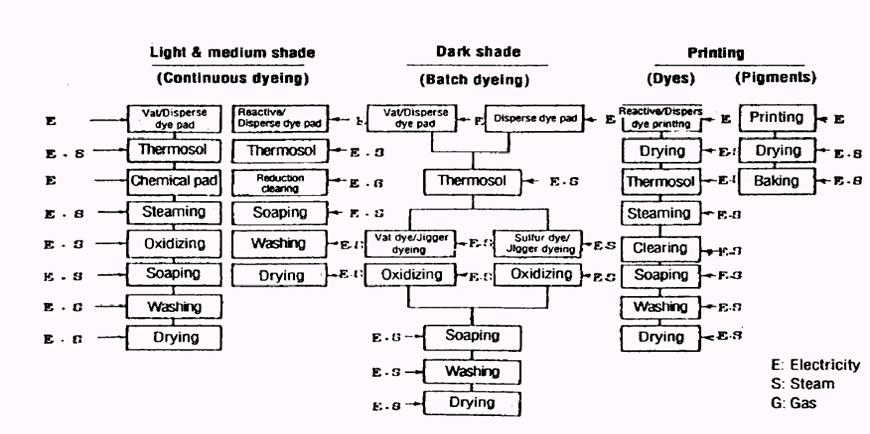

- Typical dyeing processes and energy use for cotton fabric

Literature:Handy Manual: Textile industry,Output of the Seminar on Energy Conservation in Textile Industry, United Nations Industrial development Organization (UNIDO) and Ministry of International Trade and Industry (MITI, Japan), 1992)

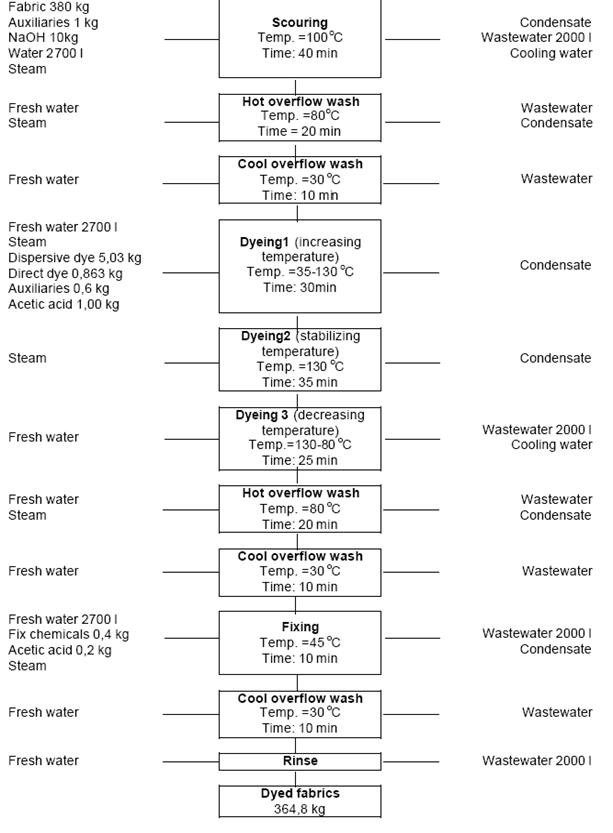

- Typical parameters of the process

| Techniques | Temperature [°C] | Pressure (bar) | Heat transfer medium | Residence Time | Additional information | Literature |

| Batch dyeing or Exhaustion dyeing | 100 | Hot water | 30 min | direct dyes | manuale page 979 | |

| Semi- continous (Pad jig) | 60-85 | Hot water | direct dyes | |||

| Semi- continous (Paed roll) | 90 | Hot water | 2-8 h | direct dyes | ||

| Continous (Pad steam) | 60-85 | Hot water | direct dyes; steaming at 100-105°C | manuale page 980 |

- Energy consumption

| Fibres/Fabrics etc. | Process/technique | Electricity [kWh/kg] | Thermal energy [MJ/kg] | Water for dyeing [l/kg] | Water for rinsing [l/kg] | Dyestuff | Literature |

| Cotton loose fibre | dyeing | 0,1-0,4 | 4-14 | 8-15 | 8-16 | direct, reactive dyes | BAT in textile industry, 2003 |

| Cotton yarn | dyeing | 0,8-11 | 13-16 | 15-30 | 45-60 | direct dyes | |

| Cotton yarn | dyeing | 0,8-1,1 | 13-16 | 15-30 | 60 | reactive dyes | |

| Cotton yarn | dyeing | 0,8-1,1 | 13-16 | 100-150° | sulphuric dyes |

°total water consumption