Dyeing of vicose, cupro & modal(regenerated

From Efficiency Finder

Revision as of 12:23, 16 November 2010 by Breka (Talk | contribs) (Protected "Dyeing of vicose, cupro & modal(regenerated" [edit=autoconfirmed:move=autoconfirmed])

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

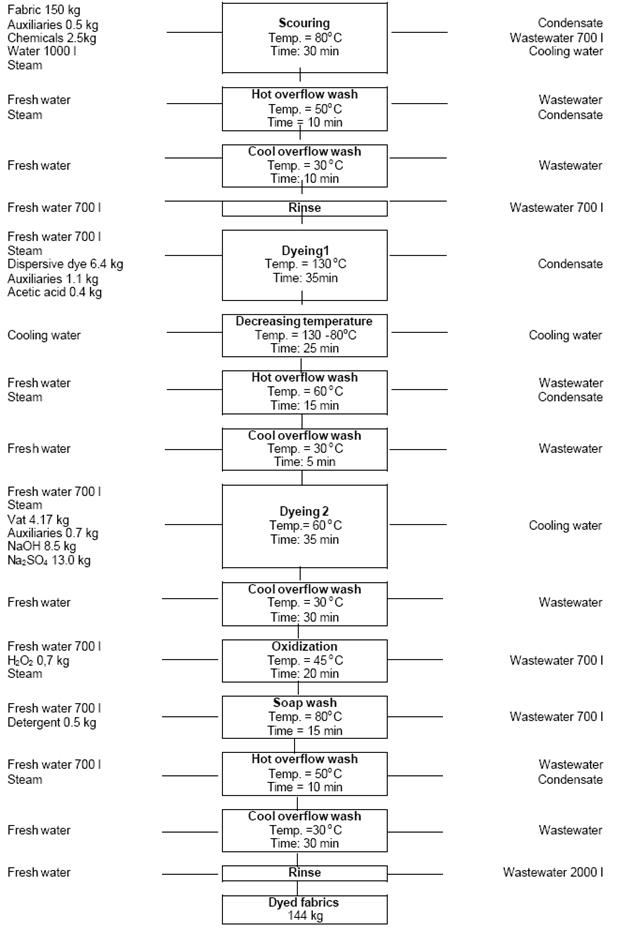

- Flowsheet

Literature: UNIDO CP Unit Technical Report, https://www.unido.org/NCPC/ReportTexts/NCPC00000015.pdf

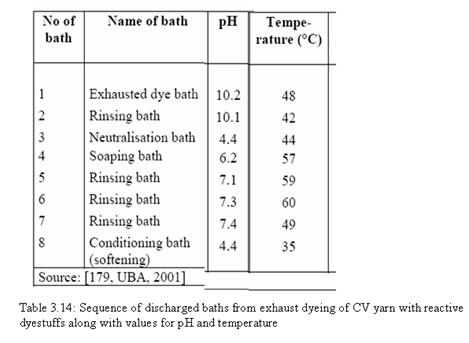

- Typical parameters of the process

| Techniques | Temperature [°C] | Pressure (bar) | Heat transfer medium | Residence Time | Additional information | Literature |

| Batch dyeing or Exhaustion dyeing | 100 | Hot water | 30 min | direct dyes | manuale page 979 | |

| Semi- continous (Pad jig) | 60-85 | Hot water | direct dyes | |||

| Semi- continous (Paed roll) | 90 | Hot water | 2-8 h | direct dyes | ||

| Continous (Pad steam) | 60-85 | Hot water | direct dyes; steaming at 100-105°C | manuale page 980 |