Expandable or foam polystyrene (EPS)

Back to Information about polystyrene

1 General description

The techniques used for the production of expandable polystyrene (EPS) beads and their processing to expanded polystyrene foams were developed at the end of the 1940s by BASF who marketed the new raw material under the trade name Styropor. Due to licensing and the expiry of patents, other raw material manufacturers and trade names have appeared. Expandable polystyrene is produced by suspension polymerisation of styrene with the addition of blowing agents; the resulting polymer beads are then sieved into various bead sizes. Depending on the end use, different coatings may be applied. In their final form, EPS foams contain about 95 % air by volume. The most important product properties of EPS foams are their excellent thermal insulation, good strength and shock absorption even at low densities. The major applications of lightweight rigid EPS foam in Europe are in the construction industry, as thermal insulation for walls, cavities, roofs, floors, cellars and foundations. Boards, either cut to shape from blocks or contour-moulded at densities typically ranging from 10 – 50 kg/m3, are used either as such or in combinations with other building materials, to manufacture laminated elements, sandwich panels, etc. The success of EPS foam as a packaging material is based upon overall properties as well as its costeffectiveness. Moulded boxes are equally suitable for packing highly sensitive instruments, fragile glass, ceramic products and heavy machine parts, as well as for perishable food such as fish, fruit and vegetables. EPS packaging has contributed to outstanding savings by reducing damage, shipping weight and labour costs.

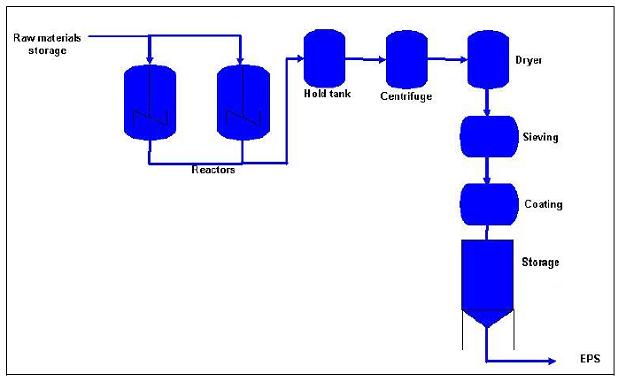

2 Flow diagram of EPS production

Figure 1: Flow diagram showing EPS production

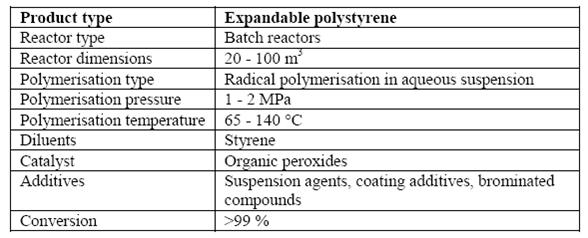

3 Technical parameters

Table 1: Technical parameters of EPS

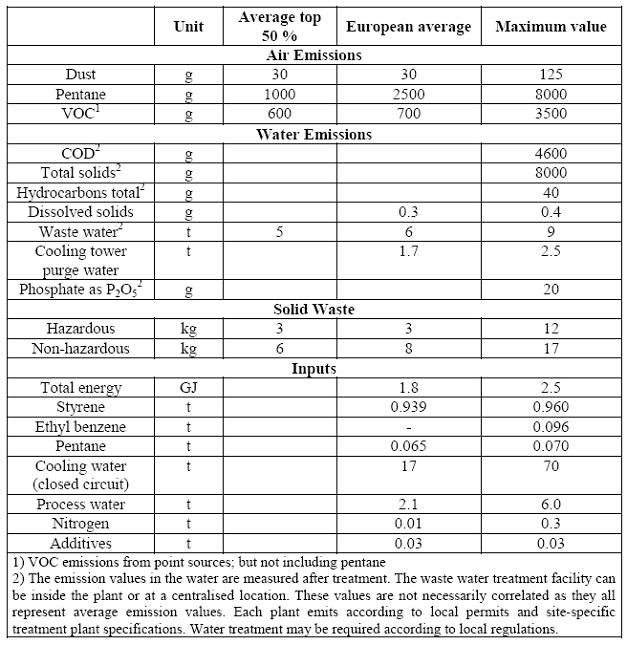

4 Emission and consumption data of EPS plants

Table 2: Emission and consumption data of EPS plants

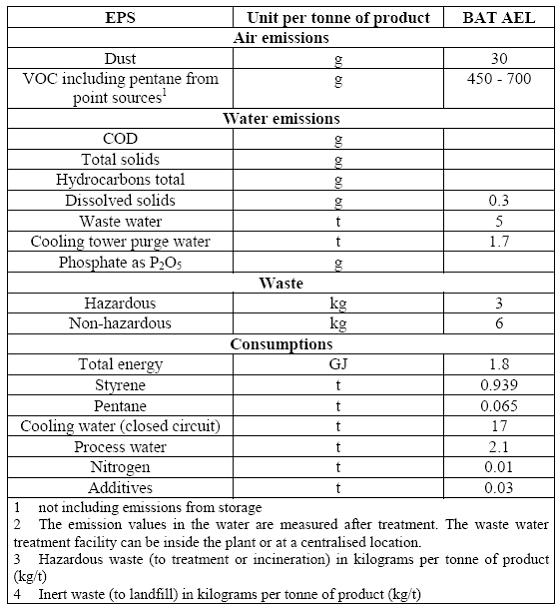

5 Emission and consumption levels associated with BAT for the production of polystyrene

Table 3: BAT associated emission and consumption levels (BAT AEL) for the production of EPS

Literature: BAT for Polymers, October 2006

Back to Information about polystyrene