Extraction

Back to EFFICIENCY FINDER

1. OBJECTIVE

The objective of extraction is to remove one constituent from a solid or liquid by means of a liquid solvent. These techniques fall into two categories: the first is used to dissolve soluble matter from its mixture with an insoluble solid and it’s called leaching or solid extraction and the second is used to separate two miscible liquids by the use of a solvent that preferentially dissolves one of them and it’s called liquid extraction (Unit Operations of Chemical Engineering, McCabe, Smith, Harriot, 5th Edition, McGrawHill).

2. FIELD OF APPLICATION

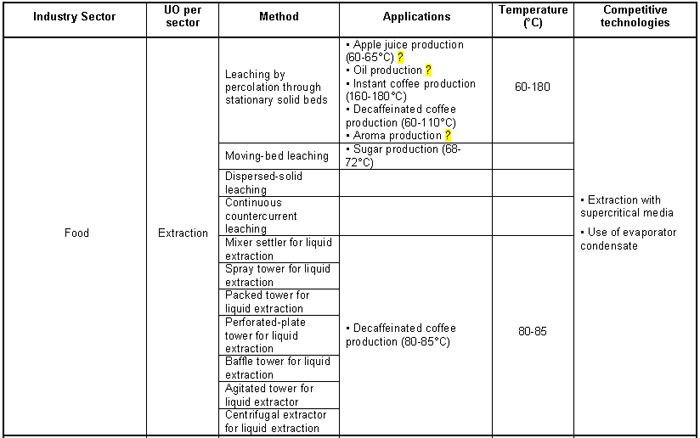

Extraction is widely used in food and chemical industries.

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Leaching equipment: (Unit Operations of Chemical Engineering, McCabe, Smith, Harriot, 5th Edition, McGrawHill

There are two methods of leaching, according to the properties of the solid material:

- When the solids form an open, permeable mass throughout the leaching operation, solvent may be percolated through an unagitated bed of solids. The method may be either batch or continuous.

- With impermeable solids or materials that disintegrate during leaching, the solids are dispersed into the solvent and are later separated from it. Moving bed leaching or dispered-solid leaching can be used. The methods may be either batch or continuous.

- Principles of continuous countercurrent leaching: (Unit Operations of Chemical Engineering, McCabe, Smith, Harriot, 5th Edition, McGrawHill)

The most important method of leaching is the continuous countercurrrent method using stages. Even in an extraction battery, where the solid is not move dphysically from stage to stage, the charge in any one cell is treated by a succession of liquids of constantly decreasing concentration as if it were being moved from stage to stage in a countercurrent system. The continuous countercurrent method is a very important leaching method. In this case, the liquid and the solid flow countercurrently into different stages, in each of them equilibrium is attained and mass is transferred between the two phases. The multiple stages by which leaching is achieved result in more satisfactory mass transfer comparing to other leaching methods, therefore the solid/liquid separation is more efficient.

- Liquid extraction equipment: (Unit Operations of Chemical Engineering, McCabe, Smith, Harriot, 5th Edition, McGrawHill)

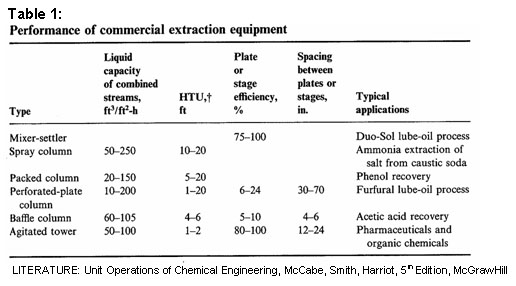

In liquid extraction, as in gas absorption and distillation, two-phases must be brought into good contact to permit transfer of material and then be separated. In extraction, the two-phases have comparable densities, so that the energy available for mixing and separation- if gravity flow is used- is small, much smaller than when one phase is a liquid and the other one is a gas. The two phases are often hard to mix and harder to separate. The viscosities of both phases, also, are relatively high and linear velocities through most extraction equipment are low. In some types of extractors, therefore, energy for mixing and separation is supplied mechanically. Extraction equipment may be operated batchwise or continuously. A quantity of feed liquid may be mixed with a quantity of solvent in an agitated vessel, after which the layers are settled and separated. The extract is the layer of solvent plus extracted solute, and the raffinate is the layer from which solute has been removed. The extract may be lighter or heavier than the raffinate and so the extract msy be shown coming from the top of the equipment in some cases and from the bottom in others. The operation may of course be repeated if more than contact is required, but when the quantities involved are large and several contacts are needed, continuous flow becomes economical. Most extraction equipment is continuous with either successive stage contacts or differential contacts. Representative types are mixer-settlers, vertical towers of various kinds that operate by gravity flow, agitated tower extractors and centrifugal extractors. The table below lists the characteristics of various type of extraction equipment:

4. RELEVANT PARAMETERS TO ENERGY

- Temperature

- Pressure

- Medium

- Solid- or liquid-to be extracted characteristics (e.g. solubility, density)

Back to EFFICIENCY FINDER