Difference between revisions of "Finishing of cotton and bast fibres"

From Efficiency Finder

m (Protected "Finishing of cotton and bast fibres" [edit=autoconfirmed:move=autoconfirmed]) |

m (Changed protection level for "Finishing of cotton and bast fibres" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

(No difference)

| |

Latest revision as of 11:57, 1 March 2013

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

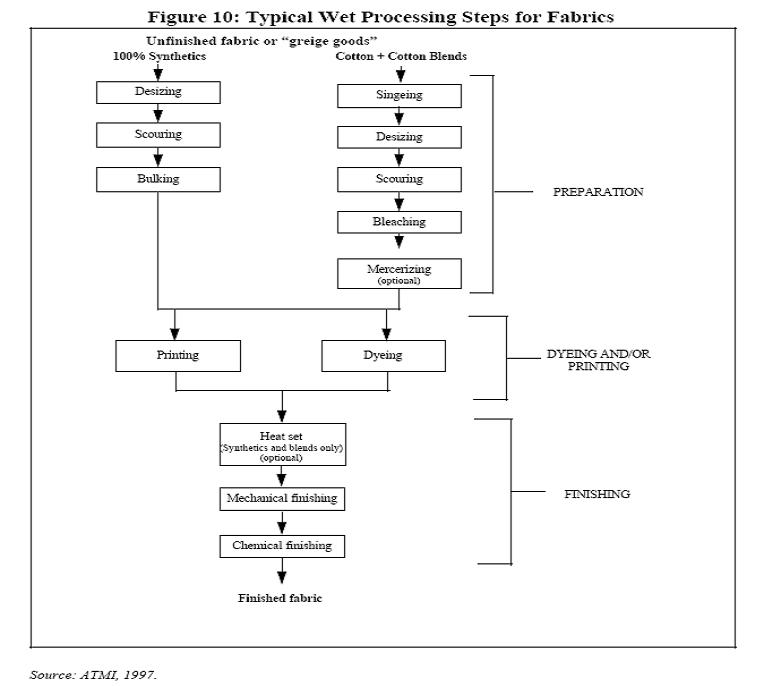

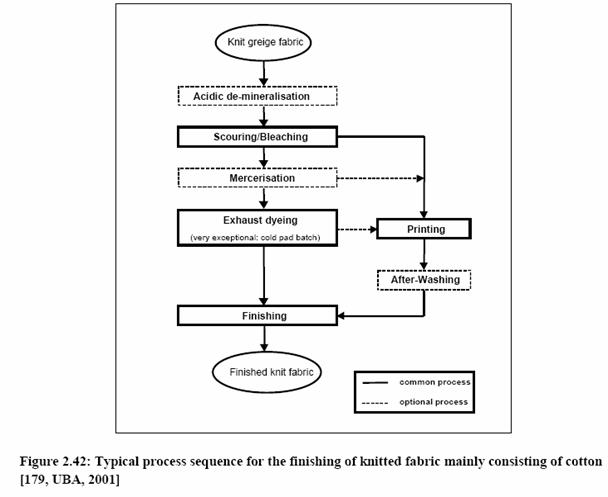

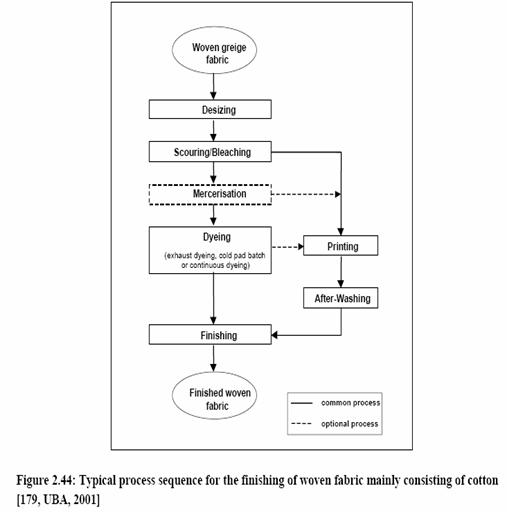

- Cotton finishing Flowsheet

a) Typical wet processing for fabrics

b) Typical process sequence for the finishing of cotton knitted fabric

c) Typical process sequence for the finishing of cotton woven fabric

- Typical parameters of the process

| Techniques | Temperature [°C] | Pressure (bar) | Heat transfer medium | Residence Time | Additional information | Literature |

| New technology: plasma treatment | not above 60 | 50-150 Pa | gas transformed to plasma in an electrical field |

- Energy consumption

| Fibres/Fabrics etc. | Process/technique | Total energy consumption [kWh/kg] | Electricity [kWh/kg] | Water consumption [l/kg] | Literature |

| yarn, mainly CO | finishing mill | ca. 11 | 2 | 70-120 | BAT in textile industry 2003 |

| knitted fabric, mainly CO | finishing mill | 6-17 | 1-3 | BAT in textile industry 2003 | |

| woven fabric, mainly CO | finishing mill | 8-20 | 0,5-1,5 | BAT in textile industry 2003 |