Founding of steel cast

Back to Subsection DC metals

Steel casting

Steel is a material of which the (mass) content of iron is bigger than that of any other element, with a carbon content generally lower than 2%, and which also usually contains other elements. A limited number of chromium steel types may contain over 2 % carbon, but 2 % is the usual cut-off limit used to distinguish steel from cast iron [201, CEN, 2000]. One particularly useful aspect of steel is that it can be hot worked. Low alloy cast steel contains elements such as Mn, Cr, Ni, and Mo in amounts less than 5 %. High alloy steel includes more than 5 % of alloying elements, e.g. 12 % Cr and 8 % Ni. Special steel grades are produced with enhanced properties, such as higher strength; higher magnetic permeability; better resistance to corrosion, fatigue or wear; and improved behaviour during welding or at high or low temperatures.

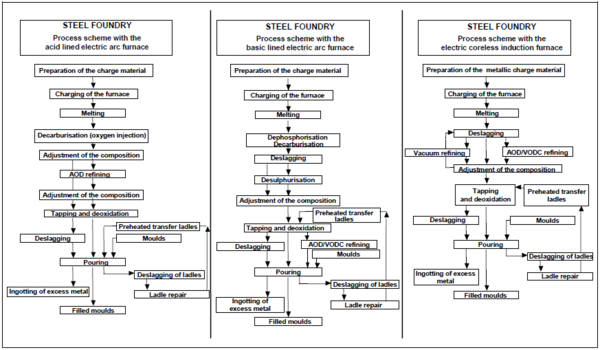

Cast steel is normally melted in electric arc furnaces (EAF) or in coreless induction furnaces (IF). Once melted, the liquid metal can be refined (i.e. removal of carbon, silicon, sulphur and or phosphorus) and deoxidised (i.e. reduction of metallic oxides), depending on the base material and the quality requirement of the finished product . Figure 1 gives process flow diagrams for the melting and metal treatment of cast steel in the different furnace types. [32, CAEF, 1997]

Figure 1: Process flow diagrams for the melting and metal treatment of steel [32, CAEF, 1997]

Source: European Commission, Reference Document on Best Available Techniques in the Smitheries and Foundries Industry, May 2005, p.17-18

Back to Subsection DC metals