Difference between revisions of "Handbook"

(→Utilities) |

(→Fermentation) |

||

| Line 435: | Line 435: | ||

:*The '''energy supply''' is likely to come from different sources (e.g. thermo-oil for baking power, steam inlet for steaming, electricity for lighting) | :*The '''energy supply''' is likely to come from different sources (e.g. thermo-oil for baking power, steam inlet for steaming, electricity for lighting) | ||

:*The usage of the '''remaining vapors (from the steaming) for heat recovery''' is a key energy efficiency measure in bakeries. The condensation enthalpy of the steam is added to the pinch stream list. Currently, only the condensation enthalpy at 100°C is considered in pinch analysis. | :*The usage of the '''remaining vapors (from the steaming) for heat recovery''' is a key energy efficiency measure in bakeries. The condensation enthalpy of the steam is added to the pinch stream list. Currently, only the condensation enthalpy at 100°C is considered in pinch analysis. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

====Branch Specific Processes in Dairy==== | ====Branch Specific Processes in Dairy==== | ||

Revision as of 08:16, 27 August 2015

THIS HANDBOOK IS STILL IN PROGRESS

Contents

- 1 Tool Background

- 2 Working with the GREENFOODS branch concept

- 3 Defining the Status Quo - Energy Balancing in the GREENFOODS branch concept

- 3.1 General Input

- 3.2 Energy Sources

- 3.3 Utilities

- 3.4 Distribution

- 3.5 Processes

- 3.6 Closing the Energy Balance

- 4 Optimisation

- 5 Export results

- 6 ANNEX A - Material Data

Tool Background

Project Background

The overall objective of the GREENFOODS project is to lead the European food and beverage industry to high energy efficiency and reduction of fossil carbon emissions in order to ensure and foster the world wide competitiveness, improve the security of energy supply and guarantee the sustainable production in Europe. The GREENFOODS branch concept will guide the user to identify tailor-made solutions for “green production” for SMEs in the different subsectors in the food and beverage industry by combining technological expertise with knowledge on energy efficiency and renewable resources resulting in clear strategies for SMEs for process optimisation and energy supply towards a production without fossil carbon emissions.

Version

This handbook is designed for the GREENFOODS branch concept 4.0. Here you can find the Dowloand Link: GREENFOODS branch concept 4.0

Previous versions of the GREENFOODS branch concept have been used for internal (within GREENFOODS project consortia) revision and - later on - for the GREENFOODS training in various countries of the EU.

Working with the GREENFOODS branch concept

Download and Start the GREENFOODS branch concept

You can download the GREENFOODS branch concept from the homepage of the GREENFOODS project green-foods.eu and from the Virtual Energy Competence Centre VECC.

The GREENFOODS branch concept is an Excel Tool. Therefore there is now need to ‘install’ the tool. Make sure you save the file in a directory where you do not need administrator rights. Open the GREENFOODS branch concept with an ordinary double-click on the file.

A security warning may show up (see picture below) and you may need to activate the contents or allow macros to be activated.

You will see following screen. Start the GREENFOODS branch concept with a click on the green error.

Selection of a Branch in the GREENFOODS branch concept

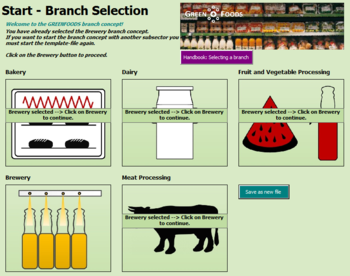

You may select any of the 5 branches in the GREENFOODS branch concept.

|

Once you select a branch you are immediately forced to save the Excel-File as a new version. |

After this initial saving process you will have two versions of the Greenfoods Branch Concept:

- Version 1: The original version. It is now closed. No branch is selected. It can be used for new projects.

- Version 2: The current version. It is now open. A branch is selected which cannot be changed in this version.

Additional information on the savings can be found 'here'.

Effects of the branch selections

- The general input form will be individualized to the selected branch

- The benchmark data is individualized to the selected branch

- The relevant processes are activated for the selected branch

- WikiWeb information (buttons) are individualized

Saving your work

| How to... | |

| ...save as new file | 1) when selecting a branch in GF BC

2) when clicking “save as new file” in the “branch selection” form |

| ...save changes in a form | by clicking on the (dark green) button “Confirmed” (the changes are saved in the workbook) |

| ...save workbook (Excel-file) | use the common Excel-buttons or the shortcut Strg+S for savings |

FORMS: Entering data in the GREENFOODS branch concept

The graphical user interface of the GF BC is built in userforms (hereafter called “forms”). By using the buttons explained above, the various forms can be accessed.

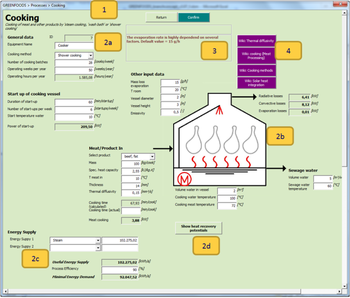

The following figure shows a typical form in the GREENFOODS branch concept (e.g. definition of the process 'cooking').

| Number | Name | Explanation |

|---|---|---|

| 1 | Top bar + Headline | The top bar of the form shows the navigation place of the form (e.g. … > Processes > Cooking)

The headline is supported with additional information on the particular form. |

| 2a | Entry: General | All process-(or utility-)forms will receive a new process-(or utility-)ID. A name must be entered for each process/utility. |

| 2b | Entry: Energy demand | The energy demand of the processes can be calculated in different ways. The calculation is supported by flowsheets or images for better understanding. |

| 2c | Entry: Energy supply | The defined energy demand must be met by energy supply. This section is identical in all process and utility forms.

In utility forms, all energy sources can be selected as energy supply. In process forms, all distribution lines can be selected as energy supply. |

| 2d | Entry: Heat recovery | Heat recovery optimization is an important part of the GF BC. Each provides different heat sinks and heat sources. |

| 23 | Info: Quick | By moving the mouse over fields and images the user gets additional information on the meaning of the field and the required input. |

| 4 | Info: WikiWeb | Most forms have several links to the WikiWeb indicated by purple color. |

|

The X-Button on the top right corner will close the form. The changes of the current form will NOT be saved. However, all previously saved forms will be available for further processing. The user can immediately start the BC again by click on the green start arrow. |

| |

dark green | confirmation / changes are saved |

| |

light green | returning / changes are not saved |

| |

red | economics / optimization / benchmark |

| |

purple | hyperlink to GF WikiWeb |

FIELDS: color code and mandatory data

The fields are filled with different colours which have different meanings:

| Number | Name | Explanation |

|---|---|---|

| 1a | Mandatory field (red) | Mandatory fields must be filled in order to start the calculations and save the changes |

| 1b | Filled mandatory fields (white) | As soon as mandatory fields have valid data filled, the color changes to white. However, certain restriction might lead to a recoloring to red again.

Some fields are white from the beginning, meaning that the entry is not mandatory but optional. |

| 1c | Calculated fields (green) | Green fields are calculated based on the entries in the other fields |

| 2 | Combination boxes (red/white) | Combination boxes allow the selection of pre-defined data. Similar to ordinary fields, they may be mandatory (red) and after selection become white. |

| 3 | Check boxes | In various areas of the different forms, there is the possibility to activate/deactivate additional options. |

Using the GREENFOODS WikiWeb

The GREENFOODS WikiWeb can be accessed in many multiple areas of the GREENFODS branch concept, indicated by violet buttons.

|

→ |

|

Defining the Status Quo - Energy Balancing in the GREENFOODS branch concept

General Input

In the general input section the following basic data must be entered:

- Ambient Conditions

- Country

- Company Data

- Water Input

- Material Input (branch specific)

- Energy Input --> Linked to the Energy Flow Sheet

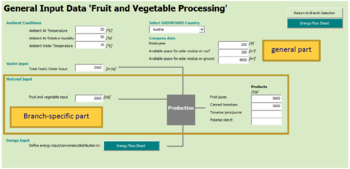

The following figure shows the General Input Data: The general part is identical in all 5 subsectors. The branch specific part (material input) is dependent on the branch selection.

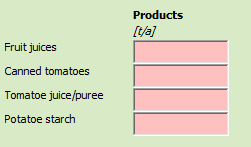

At least one product must be defined in the “material input” section:

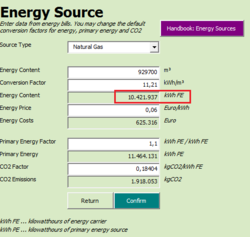

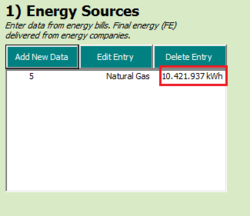

Energy Sources

In the GREENFOODS branch concept, 10 energy sources can be selected and a 11th added by the user with individual configurations. The energy value can be entered in typical units for the different energy source types (e.g. natural gas in m³, diesel in litre,...) Via a default but changeable conversion factor the energy value is transferred in kWh.

|

The GREENFOODS branch concept is designed to calculate and display all energy values in kWh. |

|

→ |

|

For a detailed economic and ecological analysis of possible optimization measures, following default factors for CO2 and primary energy are used. These values can be changed to account for national differences.

| Energy Source | CO2 | PE Factor |

|---|---|---|

| - | kgCO2/kWh | kWhPE/kWhFE |

| Coal | 0.31 | 1.05 |

| Diesel | 0.25 | 1.10 |

| Fuel Oil | 0.27 | 1.17 |

| LPG | 0.21 | 1.11 |

| Natural Gas | 0.18 | 1.17 |

| Petrol | 0.24 | 1.10 |

| Biomass (wood chips) | - | 1.06 |

| Biogas | - | 1.50 |

| District heat | 0.22 | 0.70 |

| Electricity | 0.19 | 1.00 |

Utilities

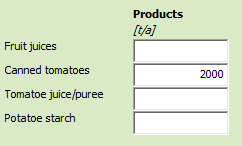

Boilers

Steam Boiler

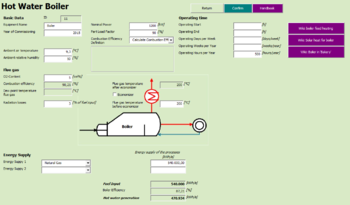

Hot Water Boiler

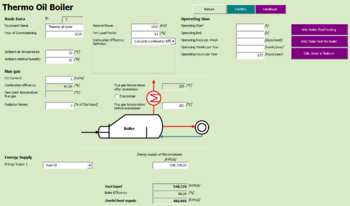

Thermo Oil Boiler

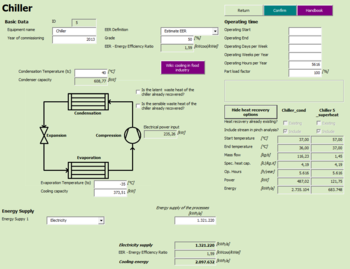

Chiller

Distribution

Processes

Typical processes in the food industry

Process Heating

Description of process

The process heating uses approximately 29% of the total energy used in the food and beverage industry. In this simple heating process the heating is realized by passing the product through a heat exchanger. Depending on the heating process, different methods can be used to achieve energy savings. For example, the re-use of waste water streams of the process for heat recovery is an effective way to reduce the energy consumption. Therefore this process heating also shows the heat recovery potentials.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Process Cooling

Description of process

The processes cooling and refrigeration use approximately 16% of the total energy used in the food and beverage industry. The aim of the cooling process is to reduce or maintain the temperature of a product in a lower level. In this simple cooling process the cooling is realized by passing the product through a heat exchanger.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Cleaning in Place (CIP)

Description of process

Cleaning in place (CIP) is a commonplace method in the food and beverage industry. CIP allows cleaning the interior surfaces of tanks and pipeline circuits without disassembly. Hereby it is possible that the process plant and pipework is cleaned between the process runs. The main purpose of CIP is to remove solids and bacteria from vessels and pipework to meet the stringent hygiene regulations in the food and drink industry. CIP can be carried out with automated or manual systems.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Drying (basic)

Description of process

During the drying process water or other liquid is removed from a solid material by evaporation. Usually drying is the final step of operations and the product is ready for packaging and selling. Especially for foods drying is necessary and the most useful operation method to keep foods safe for a long time. For drying food there are a huge number of methods and processes. In this process the inlet and outlet of the gas stream, e.g. air is not considered.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Cooling Chamber

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Space Heating and Cooling

Description of process

Production halls and offices have to be heated and increasingly commonly cooled. Space heating and cooling can be done by ordinary radiators, surface heating or ceiling spots. The equipment are supplied with a hot medium, some may be driven electrically. Heating and cooling of production halls and offices can have a high share of the energy demand in less energy intensive production facilities. It can be an important heat sink for waste heat integration.

Method of calculating energy demand

In order to determine the energy demand for heating and cooling the production facilities and offices the area [m²] and specific heating/cooling demand [kWh/m².a] can be entered. Additionally, heating/cooling hours as well as supply and return temperatures are defined so the data can be used as heat sinks and sources in the heat integration analysis.

File:Fig processes space define.png

Multiple areas can be defined which have heating and/or cooling demand. The areas are listed in a heating and a cooling section and can be edited or deleted anytime.

File:Fig processes space areas.png

The “total space heating demand” and the “total space cooling demand” require a connection with an energy supply from the distribution list. It is possible to define 3 energy supplies. If both heating and cooling takes place then at least one “heating source” and one “cooling source” must be assigned, additionally a third source (either heating or cooling) may be selected.

Formula to determine energy demand

Where:

| Formular | Description | Unit |

|---|---|---|

| Q | Energy demand | [kWh/a] |

| q(i) | Specific energy demand of space | [kWh/a.m²] |

| A(i) | Area of space | [m²] |

| i | space Number |

Embedding in branch concept

- The energy supply may be split into heating and cooling sources

- Space heating is an important heat sink for heat recovery measures in many cases. It is added as a cold stream in the heat recovery analysis. The extracted heat from cooled spaces can technically serves as heat source for heat recovery or heat pumps, but it is not likely to be actually used. However, it is still included in the stream list as hot stream.

Washing Line

Description of process

In several food industries, bottles and cases are used when packaging final products. The bottles and cases are in direct contact with the food and therefore they must be cleaned sufficiently before they are used. During the cleaning process possible food residues, dirt and odors from the packaging containers are removed. Thereby the microbiological load is minimized according to hygiene and health regulations. For the cleaning process high temperature water is necessary.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Black box (simple definition)

Description of process

The black box can be used if there is no other specific form which can define the process. The energy demand is calculated simply by the mass of the incoming product as well as the start and target temperature, the heat capacity and the operating hours of the process.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

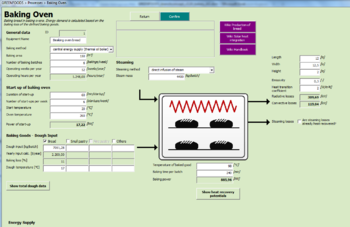

Branch Specific Processes in Bakery

Baking Oven

Description of process

The baking process transforms an unpalatable dough into a light, readily digestible, porous flavourful product. The physical activities involved in this conversion are complex but the fundamentals of these are explained here: Information about bread The internal loaf temperature increases to reach approximately 98°C. The loaf is not completely baked until this internal temperature is reached. Weight is lost by evaporation of moisture and alcohol from the crust and interior of the loaf. Steam is produced because the loaf surface reaches 100°C+. As the moisture is driven off, the crust heats up and eventually reaches the same temperature as the oven.

Method of calculating energy demand

The unit operation “baking” is related to the drying operation. The process involves the evaporation of water in the dough which is known as the baking loss.

The baking loss is the ratio between water loss during baking and dough input.

Additionally, at the beginning of the baking process steam is supplied to the baking oven for better heat conductivity of the baking goods. If the required steam is generated by the baking oven itself (e.g. internal electrical steam generator) then the necessary energy demand is calculated. If, however, steam is supplied directly from a stream distribution line, then the respective amount of energy must be assigned in the energy supply section. The heating of the cold dough is also considered in the energy demand.

For the startup of the oven only the heating of the air is considered, but not the heating of oven-material.

Heat losses are comprised of radiative and conductive heat losses.

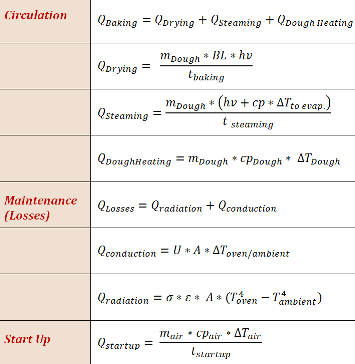

Formula to determine energy demand

Where:

| Formular | Description | Unit |

|---|---|---|

| Q(Baking Oven) | Baking Power | [kW] |

| m(Dough) | Mass input of dough | [kg/batch] |

| BL | Baking Loss | [kg water / kg dough] |

| hv | Evaporation enthalpy water | [kJ / kg water] |

Embedding in branch concept

- The total dough input of 4 baking goods can be defined in the “General Input” form. The definition of the baking loss is also defined there.

- The energy supply is likely to come from different sources (e.g. thermo-oil for baking power, steam inlet for steaming, electricity for lighting)

- The usage of the remaining vapors (from the steaming) for heat recovery is a key energy efficiency measure in bakeries. The condensation enthalpy of the steam is added to the pinch stream list. Currently, only the condensation enthalpy at 100°C is considered in pinch analysis.

Branch Specific Processes in Dairy

Spray Dryer

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

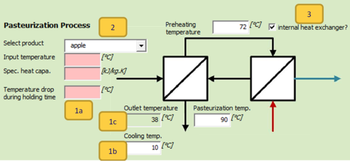

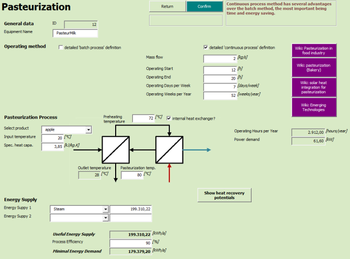

Pasteurization

Description of process

Pasteurisation is a controlled heating process used to eliminate any dangerous pathogens that may be present in milk, fruit-based drinks, some meat products, and other foods which are commonly subjected to this treatment. Pasteurization inactivates most viable vegetative forms of micro-organisms but not heat-resistant spores. As well as the application to inactivate bacteria, pasteurization may be considered in relation to enzymes present in the food, which can be inactivated by heat (BAT in the Food, Drink and Milk Industries, June 2005) Pasteurisation is used to treat all types of food products. These include milk, juices, beer and many others. [[1]]

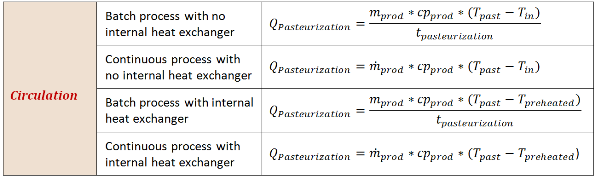

Method of calculating energy demand In order to calculate the energy demand of pasteurization, the user has 4 options:

- Batch process with no internal heat exchanger

- Continuous process with no internal heat exchanger

- Batch process with internal heat exchanger

- Continuous process with internal heat exchanger

Energy is needed to heat up the medium to the pasteurization temperature and hold it for several seconds or minutes.

Formula to determine energy demand

Embedding in branch concept

- For heat recovery the heating of the product is added as a pinch stream (if there is already an internal heat exchanger the remaining heat demand is added). Similarly, the cooling of the product after pasteurization is also added as a pinch stream.

- All available energy sources can supply to this process

- Additional information on emerging technologies in this area is available in the WikiWeb.

Evaporation

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Cheese production

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Branch Specific Processes in Fruit and Vegetable Processing

Convective Dryer (Air)

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Spray Dryer

Description of process

Link to dairy

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Pasteurization

Link to pasteurization in dairy

Evaporation

Link to Evaporation in Dairy

Packaging/Filling

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Peeling

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Blanching

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Branch Specific Processes in Brewery

Brewhouse

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Fermentation

Link to Bakery

Packaging/Filling

Link to Bakery

Branch Specific Processes in Meat Processing

Cooking

Description of process

Cooking is a heat processing technic for making food edible. Furthermore cooking also changes the texture, colour and moisture of the food. There are different methods of cooking e.g. water bath, shower and steam. Water bath ovens allow the best homogeneity of heating to be obtained. The immersion into hot water causes weight loss which and results that proteins and greases are released into the water. A shower oven allows a good uniformity of heating. It includes the simultaneous action of water sent through the shower and the saturated steam which rises from the collecting basin, at the bottom of the oven, which is heated, in turn, by coils. Hot air ovens are able to control the surface humidity if necessary and include a steam inlet and a recirculation of hot air which is obtained by passage of through heat-exchanger.

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Hot Smoking

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Cold Smoking

Description of process

Method of calculating energy demand

Formula to determine energy demand

Embedding in branch concept

Packaging

Link to Fruit

Closing the Energy Balance

Optimisation

Benchmark Analysis

Process Optimisation

System Optimisation

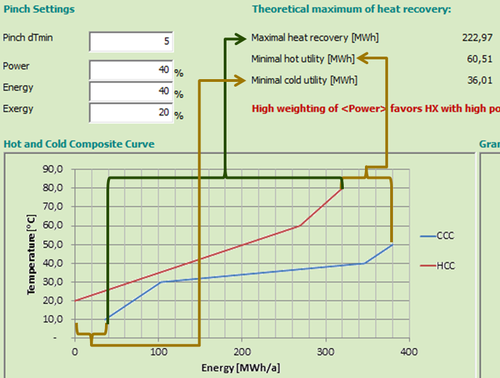

For the system optimization of the company under investigation the GREENFOODS branch concept has incorporated a Pinch Analysis, which is a methodical approach of identifying heat recovery potentials and setting up a heat recovery network.

For Pinch Analysis it is necessary to retrieve all possible thermal energy streams that must be either heated up (=cold streams) or can/must be cooled down (=hot streams). The summary of this streams is called the pinch stream list.

There are 2 ways to get the data for the pinch stream list:

- The GF BC automatically retrieves the data of hot and cold streams from the process and utility definitions while setting up the energy balance of the status quo.

- In the Pinch Analysis Form, the user can add extra streams that are not considered in the energy balance before.

Via vectorial addition, all hot streams are combined to the “hot composite curve” = (HCC) and all cold streams are combined to the “cold composite curve” = (CCC).

It is important to note that the Pinch Curves show only the process and extra streams but not the utility streams.

| Input field | Explanation |

|---|---|

| Pinch dTmin | Minimal temperature difference of heat exchangers in the heat recovery network to transfer heat from the hot side to the cold side.

Thus, the HCC must have the same distance to the CCC at the narrowest point. This point is called the Pinch which gives this method its name. |

| Criteria for Heat Exchanger Network | The 3 criteria must sum up to 100%. They determine the ranking of suggested heat exchangers in the next form. |

| Power | HX with high thermal power [kW] are favored. |

| Energy | HX with high energy transfer [MWh] are favored. |

| Exergy | HX with little temperature difference between hot inlet and cold outlet are favored. |

| Maximal heat recovery | Theoretical maximum of heat recovery at given deltaTmin. |

| Minimal hot utility | Theoretical minimum of hot utility if all heat recovery potentials are exploited. |

| Minimal coldutility | Theoretical minimum of cold utility if all heat recovery potentials are exploited. |

The Grand Composite Curves gives better insights in the placement of utilities and the actual required temperature level of the processes.

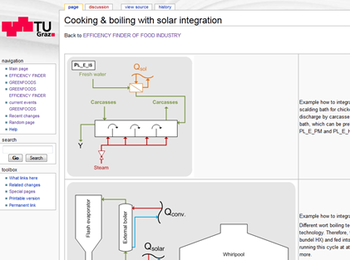

Integration of Renewables

Solar Thermal Heat for Industrial Processes

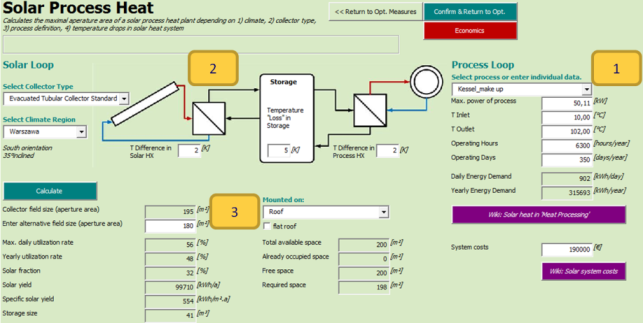

| Number | Name | Explanation |

|---|---|---|

| 1 | Process Loop | Cold streams can be selected in the combination box (thermal power, temperatures and operating hours are loaded in the fields below) |

| 2 | Solar Loop and Solar Storage | In order to provide heat to the selected process, different climate regions and temperature drops in the supply network can be defined.

4 different collector types can be compared. |

| 3 | System performance | After clicking the ’Calculate’ button the collector fields size and the required mounting area (besides other key solar performance indicators) are calculated. The required mounting area is compared with the available space defined in the General Input form |

Photovoltaic

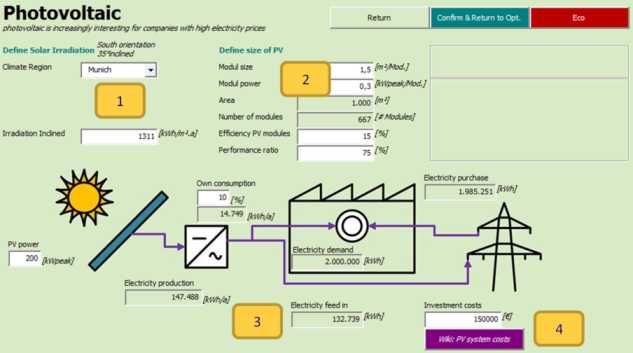

| Number | Name | Explanation |

|---|---|---|

| 1 | Define Climate Region | The inclined irradiation of the selected climate region is automatically generated. It may be adapted by the user for specific regional or inclination settings. |

| 2 | Define PV system | Typical module configurations can be entered. Information on typical values is given in the Info-box on the right hand side. |

| 3 | Define PV integration | The PV power can be varied and its effect on the company examined. The electricity demand is compared with the new PV system. |

| 4 | PV system costs | Information on typical PV system costs is given in the WikiWeb. In the Economic Analysis the whole electricity generated by the PV system is taken into account. |

Biogas

Biogas is an important potential for renewable energy production in the food and drink industry.

Details on biogas production: [2]

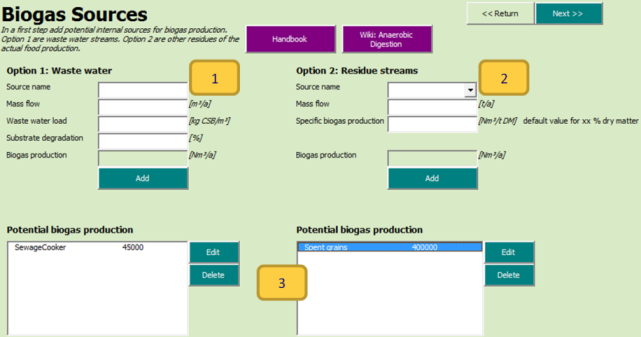

Step 1: Biogas Sources There are 2 different types of biogas sources: Option 1: waste water

| Input field | Explanation |

|---|---|

| Mass flow | Mass flow of the waste water stream |

| Waste water load | The COD (chemical oxygen demand) of the waste water must be entered |

| Substrate degradation | Percentage of the utilization of the COD potential |

For more information see: [3]

Option 2: residue streams

| Input field | Explanation |

|---|---|

| Mass flow | Yearly mass flow of the biogas source material |

| Specific biogas production | Biogas production per ton of dry material (DM) – default values are given when choosing a source |

See also Table 8 in following link: [4]

In the screenshot below can be seen how the biogas production of the two possible sources (1 and 2) is summed up and is ready for further editing (3).

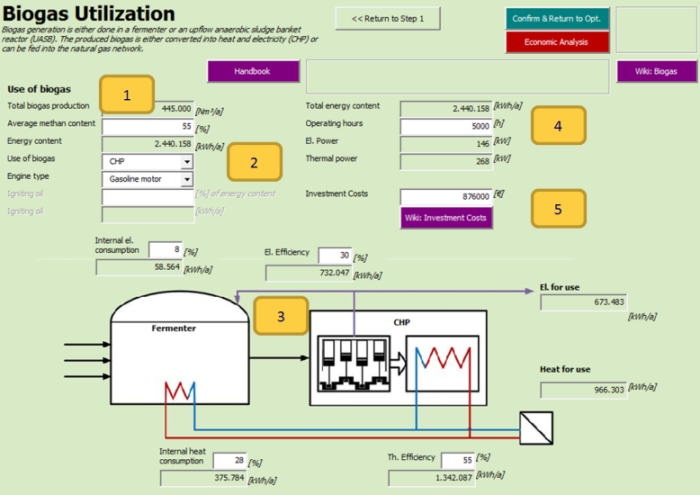

Step 2: Biogas Utilization

Key rule of the thumbs values can be found here (German): [5]

Or here (English): [6]

| Number | Name | Explanation |

|---|---|---|

| 1 | Amount of biogas | The total biogas production origins from the first step (biogas sources). Here, the ‘average methan content’ must be entered which is usually between 53-67 % as indicated in the info-box. |

| 2 | Biogas utilization | In the ‘use of biogas’ box only CHP can currently be selected. Biogas feed-in would be another method which can currently not be examined.

The engine type can also be selected. The igniting beam engine needs an additional energy source. |

| 3 | CHP definition | In the CHP flow sheet the thermal and electrical efficiency must be entered as well as the internal energy demand for the fermenter. Information on typical values is given for all fields. |

| 4 | Power and operating hours | The operating hours of the CHP must be entered. Electrical and thermal power of the CHP is calculated. |

| 5 | Investment costs | Based on the electrical power, the investment costs for the biogas fermenter + CHP can be estimated with the help of the WikiWeb |

Biomass CHP

In order to fulfill the target of the GREENFOODS project of going toward zero-fossil fuels in the food and drink industry, only biomass CHPs can be examined in the GF BC and not natural gas CHPs which are generally also considered as an efficiency improvement, however still based on fossil fuels.

More information on biomass CHP in industries can be found here: [7]

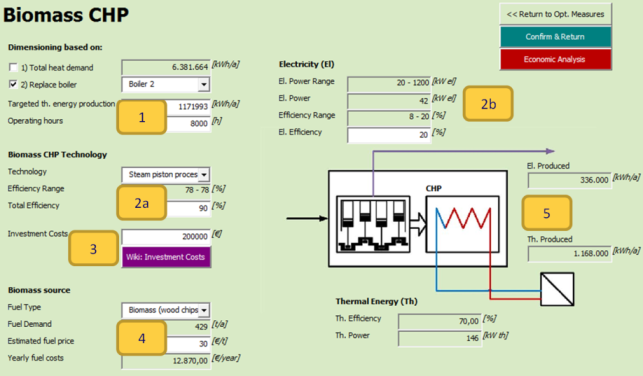

| Number | Name | Explanation |

|---|---|---|

| 1 | Dimensioning of biomass CHP | The biomass CHP can be dimensioned in 3 ways:

Option 1: Based on the total heat demand Option 2: Based on the replacement of one existing boiler Option 3: By entering an individual targeted thermal energy production |

| 2a + 2b | Biomass CHP technology | 8 different biomass CHP technologies can be selected. Some are in an experimental stadium, some have proven their applicability in practice. Depending on the selection, efficiency and power ranges are given. The user must enter the exact values manually. |

| 3 | Investment costs | The investment costs are given for each technology in the WikiWeb |

| 4 | Biomass source | Wood chips are the default biomass fuel type. The fuel demand is calculated automatically with an energy content of 3.89 kWh/kg |

| 5 | Energy generation | The produced thermal and electrical energy production is calculated based on the efficiencies, the targeted energy production and the operating hours. |

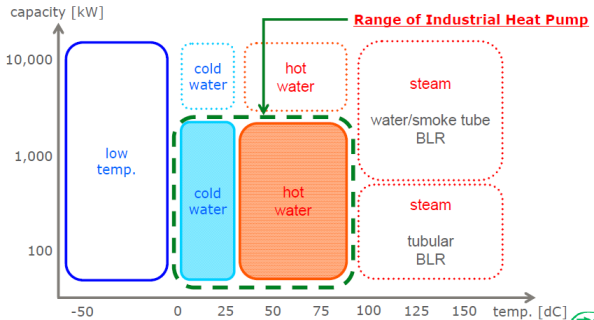

Heat Pump

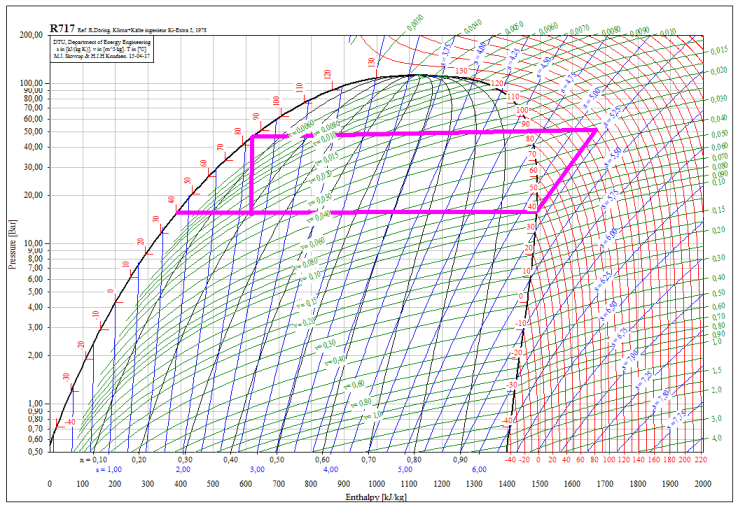

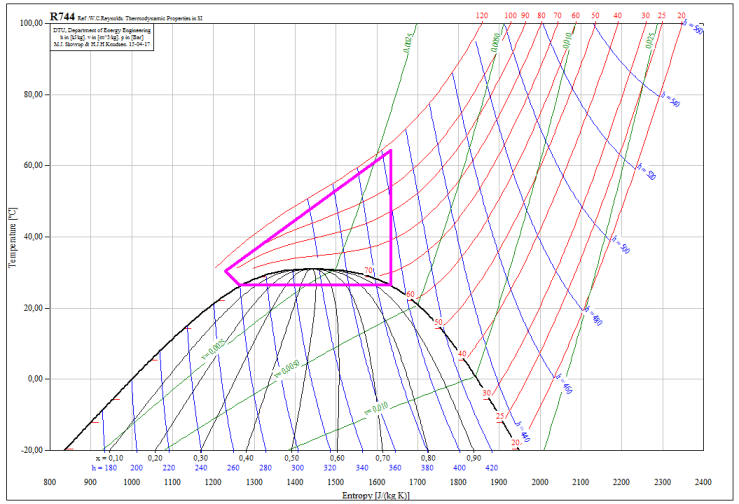

The heat pump module helps us decide if to use a heat pump to lift the temperature of a heat flow to heat up another heat flow. A low temperature waste heat flow can be upgraded to useful high temperature heat with the use of a heat pump. The mechanical heat pump type is the most commonly used. Its principle is based on compression and expansion of a refrigerant.

For large scale industrial applications, Ammonia is the most suitable refrigerant for heat pumps that deliver heat up to a temperature of 90 °C. Ammonia is considered to be one of the most efficient refrigerants. However its use comes with certain safety measures. Therefore Ammonia is mainly used for large industrial installations. The choice of refrigerant for a certain application is determined by the temperature range of its thermodynamic cycle and the size of the installation needed. Refrigerants can be divided into two groups: natural refrigerants (Butane, Ammonia, CO2) and synthetic refrigerants (R134A, R407C, R410A). For commercial applications synthetic refrigerants are favoured over natural ones. A disadvantage of synthetic refrigerants is their strong contribution to the greenhouse effect in case of leakage. The negative impact of synthetic refrigerants is, for example, 1300-2100 times higher compared to CO2.

In this tool, we will analyze 3 refrigerants: Ammonia (R717), R134 and CO2 (R744). Although new refrigerants are starting to be used with good performances (R245a), they are still not widely spread, and thus we will limit ourselves in the tool to the three forementioned. The tool will allow the introduction of new refrigerants, either transcritical or non-transcritical.

Image from Kobelco, industrial heat pump manufacturers

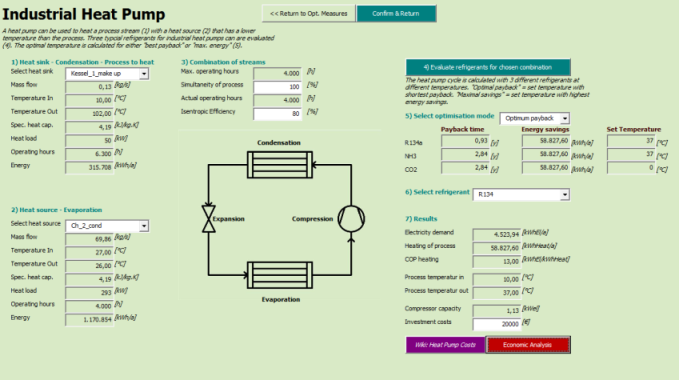

The analysis of the potential of the heat pump in the tool is done using a userform that recovers the data from the different energy flows.

In the left part of the screen, the 1) heat sink (where we will get the heat from) and the 2) heat source (where we will send the heat to) must be selected from the combo lists.

In 3) , we will introduce the percentage of hours where the heat sink and the heat source are operating at the same time. If no simultaneity exists between the flows, the number must be 0. If complete simultaneity exists, it must be 100.

In point 4), a first analysis, based on real life installations (more references in Wiki Heat Pump Costs) is done, to evaluate for the given processes which is the most interesting heat pump refrigerant. Two optimization indicators can be used, either maximum energy recovery or optimum payback.

Once we have seen the results, we select a refrigerant, and the calculation is done, to evaluate the COP, the energy recovery and, given the investment costs we introduce, a payback.

Limits are established as for temperatures.

- R717 and R134 cannot go higher than 90ºC

- For CO2 heat pumps, for a high temperature lift at the side of the gascooler (at least 30-40 °C) and a low temperature of the water that needs to be heated, the efficiency of a CO2 transcritical heat pump can be higher than conventional heat pumps. If the return temperature is higher than 30ºC, it cannot be used.

Economic Evaluation

Export results

Export Report

ANNEX A - Material Data

Emissivity of technical surfaces

| Catogory | Surface | Emissivity |

|---|---|---|

| metal | silver, polished | 0.03 |

| metal | copper, polished | 0.04 |

| metal | copper, black oxidized | 0.82 |

| metal | aluminium, bright rolled | 0.05 |

| metal | iron, bright etched | 0.16 |

| metal | iron, sanded | 0.26 |

| metal | iron, heavily corroded | 0.85 |

| other | glas | 0.88 |

| other | linoleum | 0.88 |

| other | paper | 0.89 |

| other | wood | 0.91 |

| other | mortar, plaster, concrete | 0.93 |

| other | brick | 0.93 |

| other | roofing felt | 0.93 |

| coating | aluminium-bronze coating | 0.40 |

| coating | oil paint coating, black, matte | 0.97 |

| coating | oil paint coating, black, bright | 0.88 |

| coating | oil paint coating, white | 0.89 |

| coating | radiator coating | 0.93 |