Heating of production halls in bread, biscuits and cakes

Back to EFFICIENCY FINDER OF FOOD INDUSTRY

- HEATING OF PRODUCTION HALLS IN BAKERIES

- Description

Heating of production halls is very important in winter as cooling is for summer.Energy monitoring and control systems should be installed.The non production hours set back temperatures have to be adjusted.The leakign ducts have to be repaired.Variable air volume systems adjust the rate of air flow into a room or a space based on the current air flow requirements.

Heat recovery systems reduce the energy required to heat or cool the facility intake air by recovering the thermal energy of the exhaust air/Coomon heat recovery systems include heat recovery wheels, heat pipes , and runaround loops.Ventilation fans installed in the ceilings oif work areas can help destratify workspace aur, leadign to better circulation of air.

Solar air heating systems can be employed .They use conventional steel siding painted black to absorb solar radiation for insulation. Fresh air enters the bottom of the panelswher eit is heated as it passes over the warm air absorber, and fans distribute the air.[Berkley Lab: Energy efficienct Improvement and cost saving opportunities for the bakign industry,2012]

- Applications

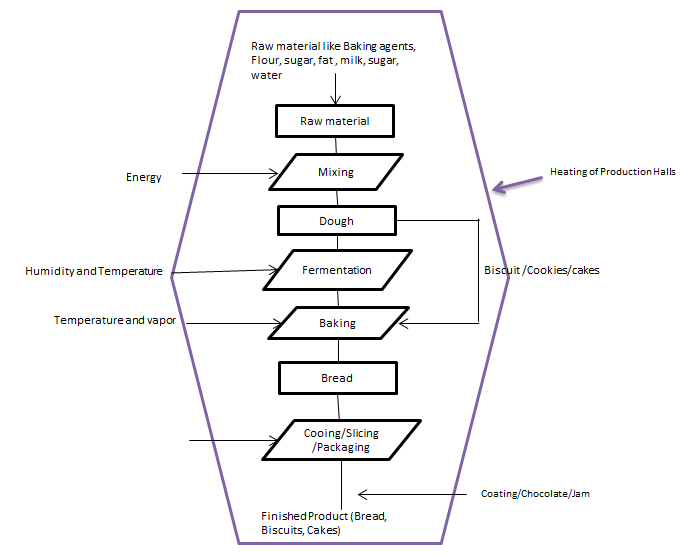

It is used in all Information about bread, biscuits & cakes production

- Example flowsheet

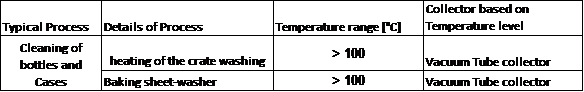

- Typical parameters of the process

Source:Bayerisches Landesamt für Umweltschutz - Minderung öko- und klimaschädigender Abgase aus industriellen Anlagen durch rationelle Energienutzung - Großbäckerei (2000)