Difference between revisions of "Information about bread"

m (Changed protection level for "Information about bread" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

|||

| Line 9: | Line 9: | ||

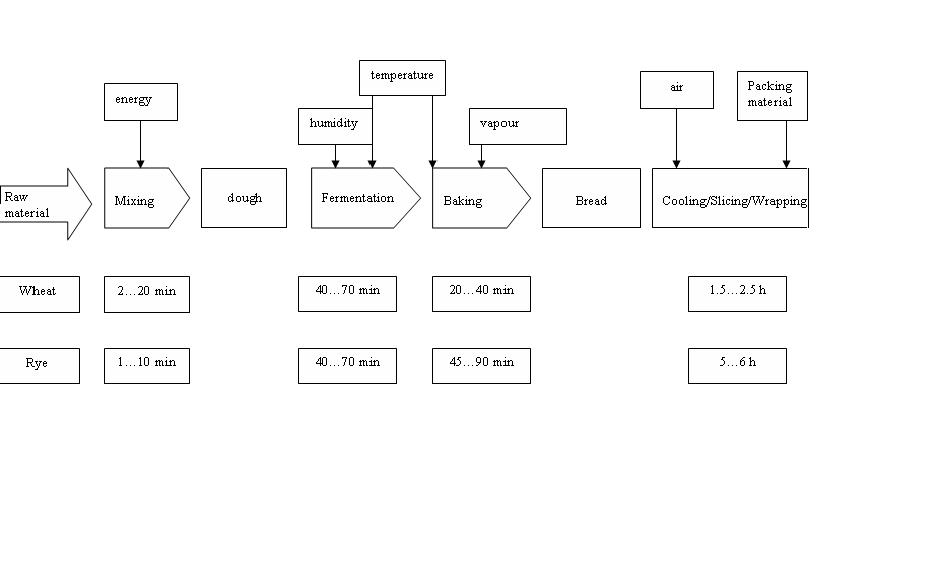

| − | ;1. General Flowsheet of bread production: | + | ;1. General Flowsheet of bread production |

| + | : | ||

| − | + | <br/>[[File:Bread production.JPG]] | |

| − | [[ | + | |

Figure 1: Production of bread. Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | Figure 1: Production of bread. Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | ||

| Line 18: | Line 18: | ||

| − | ;2. Description of techniques, methods and equipment: | + | ;2. Description of techniques, methods and equipment |

| + | : | ||

| + | |||

(BAT for Food, Drink and Milk Industries, June 2005) | (BAT for Food, Drink and Milk Industries, June 2005) | ||

| + | <br/>Bread is one of the main bakery products. It is the result of combining the four main ingredients (flour, yeast, water and salt). Different types exist, depending on the country: | ||

| − | + | <br/>''France'' | |

| − | + | ||

| − | ''France'' | + | |

80% of the total production is produced is small bakeries. Baguette is the most common eat type of bread. | 80% of the total production is produced is small bakeries. Baguette is the most common eat type of bread. | ||

| − | + | <br/>''Germany'' | |

| − | ''Germany'' | + | |

In Germany five principle types of bread are common: | In Germany five principle types of bread are common: | ||

| Line 43: | Line 43: | ||

::5. Bread specialties (by adding non- bread grains such as maize and rice or materials of animal origin such as butter, milk and yoghurt or by using special baking technique) | ::5. Bread specialties (by adding non- bread grains such as maize and rice or materials of animal origin such as butter, milk and yoghurt or by using special baking technique) | ||

| − | United Kingdom | + | <br/>''United Kingdom'' |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ::1. Sandwich bread: typical are a high volume soft texture, a fine porous crumb structure and long shelf live properties | |

| + | ::2. Malt bread: a kind of sticky, sweet and dark bread | ||

| − | Several methods for making bread exist: | + | ::3. Rye bread: commonly a 50:50 mix of wheat flour and rye flour |

| + | |||

| + | <br/>The production mostly begins with mixing flour, water and other ingredients to form a dough, By incorporation of air good volume, structure and texture is achieved during baking. | ||

| + | |||

| + | <br/>Several methods for making bread exist: | ||

*Straight dough process | *Straight dough process | ||

All ingredients are added together at the start. Then the dough ferments for 2 or 3 hours and afterward it is divided into leaf sized pieces followed by forming them into balls. After a proof time of 10-20 min they are molded and panned. | All ingredients are added together at the start. Then the dough ferments for 2 or 3 hours and afterward it is divided into leaf sized pieces followed by forming them into balls. After a proof time of 10-20 min they are molded and panned. | ||

| − | |||

| − | |||

| + | *Sponge and dough process | ||

| − | + | The sponge is prepared from part of the flour (ca. 65%), water and yeast. It is just mixed to have an uniform mixture and is then allowed to ferment for 3 or 4 hours. Then the sponge is taken back to the mixer and is mixed with the rest of the ingredients. Then it is given a floor time of 15 min to relax. | |

| − | + | *Sour dough | |

| − | + | ||

| − | + | ||

| + | Dough containing a higher proportion of flour or meal requires more acidification. This is generally achieved by sour dough process. Various types of processes were designed to increase the growth of yeast and lactic acid bacteria to give the final dough proper acidity and dough consistency. The proof time for this kind of bread is long (several hours) and for rye bread acidification is required. After the bulk fermentation the dough is divided into loaf sized pieces. Then a floor time is given which allows the dough to relax. The molding process is essentially sheeting followed by curling, rolling and application of pressure. After being molded the dough is panned and is then ready for proofing. During this step the dough increases greatly in volume and can then being baked in the oven. | ||

*Chorleywood process | *Chorleywood process | ||

| − | This kind of process is mostly common in the UK. The mixing and development of dough take place in just one single step in the presence of an oxidising agent. High quality wheat flour is required with a protein content of about 12.5% dry matter together with a high level of starch damage and hence high water absorption. Oxidising improver, fat or emulsifier and extra water and yeast are mixed in at this stage. The whole process lasts between 2 and 5 minutes. All short- time systems require high levels of oxidants. The dough mixing take place with an intensive energy input, then the dough is transferred to a hopper which is sometimes | + | This kind of process is mostly common in the UK. The mixing and development of dough take place in just one single step in the presence of an oxidising agent. High quality wheat flour is required with a protein content of about 12.5% dry matter together with a high level of starch damage and hence high water absorption. Oxidising improver, fat or emulsifier and extra water and yeast are mixed in at this stage. The whole process lasts between 2 and 5 minutes. All short- time systems require high levels of oxidants. The dough mixing take place with an intensive energy input, then the dough is transferred to a hopper which is sometimes sprayed with oil. It is divided and then allowed to rest followed by final moulding and placing into tins which were sprayed with oil before filling them. Then the dough ferments for a second time and may be cut for baking. Baking times, temperatures and temperature profiles vary largely depending on the type of bread. |

| − | The heat is transferred by direct or indirect heat to the loaf. The most common energy sources in baking industry are natural gas and electricity. | + | <br/>The heat is transferred by direct or indirect heat to the loaf. The most common energy sources in baking industry are natural gas and electricity. |

After cooling the bread is sliced before wrapping ready for distribution. | After cooling the bread is sliced before wrapping ready for distribution. | ||

| − | |||

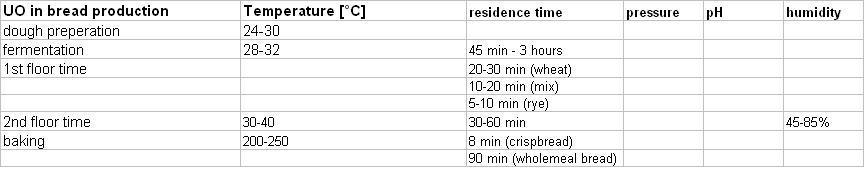

| + | ;3. Temperature ranges and other parameters | ||

| − | [[ | + | <br/>[[File:Bread production1.JPG]] |

Table 1: Parameters of UO in bread production, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | Table 1: Parameters of UO in bread production, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | ||

| − | + | <br/>The rule of thumb is: | |

| − | The rule of thumb is: | + | |

For the production of 1,5 kilo rye bread approximately 1 kilo of wheat, 850 ml of water and 30 gram of salt are required. | For the production of 1,5 kilo rye bread approximately 1 kilo of wheat, 850 ml of water and 30 gram of salt are required. | ||

| Line 90: | Line 89: | ||

The weight percent of wheat in the final product (bread) is about 65%. | The weight percent of wheat in the final product (bread) is about 65%. | ||

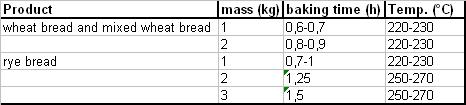

| − | [[ | + | <br/>[[File:Bread production5.JPG]] |

Table 2: Baking times and temperatures, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | Table 2: Baking times and temperatures, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | ||

| − | |||

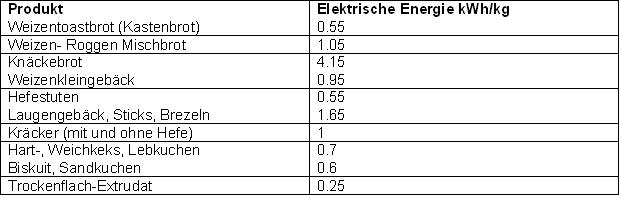

| − | [[ | + | ;4. Benchmark data |

| + | :<br/> | ||

| + | |||

| + | [[File:Bread production2.JPG]] | ||

Table 3: Energy consumption of different bakery products, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | Table 3: Energy consumption of different bakery products, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie | ||

| − | + | <br/>[[File:Bread production6.JPG]] | |

| − | + | ||

| − | [[ | + | |

| − | + | ||

Table 4: Energy Input, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | Table 4: Energy Input, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | ||

| − | + | <br/>[[File:Bread production7.JPG]] | |

| − | [[ | + | |

| − | + | ||

Table 5: Energy Input during kneading, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | Table 5: Energy Input during kneading, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit | ||

| + | |||

'''2. NEW TECHNOLOGIES:''' | '''2. NEW TECHNOLOGIES:''' | ||

| + | |||

;a) Changes in the process | ;a) Changes in the process | ||

| + | : | ||

| + | |||

;b) Changes in the energy distribution system | ;b) Changes in the energy distribution system | ||

| − | |||

| − | + | :*Heat recovery | |

| − | + | ||

| − | + | ||

| + | ::a) Description of the technology | ||

| − | + | ::Recovered heat can be used e.g. for heating sales room and the bakery and for preheating water. Because of the high rate of lost heat of the baking stoves generally no additional heating energy is required. | |

| − | + | ::b) Description of suitable energy supply systems | |

| + | ::For heat recovery several technical equipments have to be installed: | ||

| − | + | ::*Exhaust gas heat exchanger | |

| − | + | ||

| − | + | ||

| + | ::*Cloud condenser | ||

| − | + | ::*Compact heat exchanger | |

| − | + | ::*Puffer storage | |

| + | ::c) Possible energy savings reachable by those measures | ||

| − | + | ::Savings are possible in energy consumption and in CO2 emission. | |

| − | + | ||

| − | + | ||

| − | + | ||

| + | ::d) Economic evaluations | ||

| − | + | ::This type of heating system requires high investment costs, but different regional development programs already exist for supporting the companies in financial aspects. Considering the total annual costs the application of a wood pellets heating system makes sense because it offers the advantage of annual costs savings especially when the crude oil prize is high. | |

| − | : | + | ::''Reference: Kötter, A.: Abschlussbericht "Ökobäckerei mit ganzheitlichem Konzept", 2005'' |

| − | |||

| − | |||

| − | |||

| + | ;c) Changes in the heat supply system | ||

| − | |||

| − | |||

| − | + | :*Shift from fossil fuels to biomass, e.g. wood pellets | |

| − | :: | + | ::a) Description of the technology |

| − | :: | + | ::Wood pellets are used as an energy source and are are manufactured according to standardized quality standards. The decision in favor of wood pellets compared to wood chips was due to the defined quality standards and accurate calibration taken. This ensures a trouble-free automatic feeding to the oven burner and the pellet boiler. |

| − | :: | + | ::b) Description of suitable energy supply systems |

| + | |||

| + | ::In the case of a wood pellet heating system a wood pellet silo and a wood pellet stove have to be installed. Furthermore several appliances for ash recovery are required. | ||

| + | |||

| + | ::c) Possible energy savings reachable by those measures | ||

| + | |||

| + | ::Savings are possible in energy consumption and in CO2 emission. | ||

| + | ::[[File:Bread production4.JPG]] | ||

| − | + | ::Table 3: comparison of bakeries in energy consumption | |

| − | + | ||

| − | + | ||

| + | ::d) Economic evaluations | ||

| − | + | ::This type of heating system requires high investment costs, but different regional development programs already exist for supporting the companies in financial aspects. Considering the total annual costs the application of a wood pellets heating system makes sense because it offers the advantage of annual costs savings especially when the crude oil prize is high. | |

| − | + | ||

| − | This type of heating system requires high investment costs, but different regional development programs already exist for supporting the companies in financial aspects. | + | |

| − | Considering the total annual costs the application of a wood pellets heating system makes sense because it offers the advantage of annual costs savings especially when the crude oil prize is high. | + | |

| + | ::''Reference: Kötter, A.: Abschlussbericht "Ökobäckerei mit ganzheitlichem Konzept", 2005'' | ||

| − | |||

| − | Back to [[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | + | <br/>Back to [[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] |

Back to [[Information about bread, biscuits & cakes production]] | Back to [[Information about bread, biscuits & cakes production]] | ||

Revision as of 14:54, 15 November 2013

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of bread production

Figure 1: Production of bread. Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

- 2. Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

Bread is one of the main bakery products. It is the result of combining the four main ingredients (flour, yeast, water and salt). Different types exist, depending on the country:

France

80% of the total production is produced is small bakeries. Baguette is the most common eat type of bread.

Germany

In Germany five principle types of bread are common:

- 1. Wheat bread (at least 90% wheat)

- 2. Mixed wheat-rye breads (min. 50% wheat)

- 3. Mixed wheat-rye breads (min. 50% rye)

- 4. Rye breads (at least 90% rye)

- 5. Bread specialties (by adding non- bread grains such as maize and rice or materials of animal origin such as butter, milk and yoghurt or by using special baking technique)

United Kingdom

- 1. Sandwich bread: typical are a high volume soft texture, a fine porous crumb structure and long shelf live properties

- 2. Malt bread: a kind of sticky, sweet and dark bread

- 3. Rye bread: commonly a 50:50 mix of wheat flour and rye flour

The production mostly begins with mixing flour, water and other ingredients to form a dough, By incorporation of air good volume, structure and texture is achieved during baking.

Several methods for making bread exist:

- Straight dough process

All ingredients are added together at the start. Then the dough ferments for 2 or 3 hours and afterward it is divided into leaf sized pieces followed by forming them into balls. After a proof time of 10-20 min they are molded and panned.

- Sponge and dough process

The sponge is prepared from part of the flour (ca. 65%), water and yeast. It is just mixed to have an uniform mixture and is then allowed to ferment for 3 or 4 hours. Then the sponge is taken back to the mixer and is mixed with the rest of the ingredients. Then it is given a floor time of 15 min to relax.

- Sour dough

Dough containing a higher proportion of flour or meal requires more acidification. This is generally achieved by sour dough process. Various types of processes were designed to increase the growth of yeast and lactic acid bacteria to give the final dough proper acidity and dough consistency. The proof time for this kind of bread is long (several hours) and for rye bread acidification is required. After the bulk fermentation the dough is divided into loaf sized pieces. Then a floor time is given which allows the dough to relax. The molding process is essentially sheeting followed by curling, rolling and application of pressure. After being molded the dough is panned and is then ready for proofing. During this step the dough increases greatly in volume and can then being baked in the oven.

- Chorleywood process

This kind of process is mostly common in the UK. The mixing and development of dough take place in just one single step in the presence of an oxidising agent. High quality wheat flour is required with a protein content of about 12.5% dry matter together with a high level of starch damage and hence high water absorption. Oxidising improver, fat or emulsifier and extra water and yeast are mixed in at this stage. The whole process lasts between 2 and 5 minutes. All short- time systems require high levels of oxidants. The dough mixing take place with an intensive energy input, then the dough is transferred to a hopper which is sometimes sprayed with oil. It is divided and then allowed to rest followed by final moulding and placing into tins which were sprayed with oil before filling them. Then the dough ferments for a second time and may be cut for baking. Baking times, temperatures and temperature profiles vary largely depending on the type of bread.

The heat is transferred by direct or indirect heat to the loaf. The most common energy sources in baking industry are natural gas and electricity.

After cooling the bread is sliced before wrapping ready for distribution.

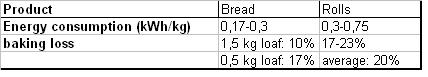

- 3. Temperature ranges and other parameters

Table 1: Parameters of UO in bread production, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

The rule of thumb is:

For the production of 1,5 kilo rye bread approximately 1 kilo of wheat, 850 ml of water and 30 gram of salt are required.

The weight percent of wheat in the final product (bread) is about 65%.

Table 2: Baking times and temperatures, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

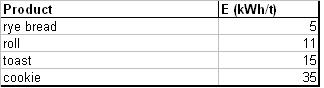

- 4. Benchmark data

Table 3: Energy consumption of different bakery products, Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

Table 4: Energy Input, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

Table 5: Energy Input during kneading, Literature: Hirschberg, H.G.: Handbuch Verfahrenstechnik und Anlagenbau, Chemie, Technik, Wirtschaftlichkeit

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- Heat recovery

- a) Description of the technology

- Recovered heat can be used e.g. for heating sales room and the bakery and for preheating water. Because of the high rate of lost heat of the baking stoves generally no additional heating energy is required.

- b) Description of suitable energy supply systems

- For heat recovery several technical equipments have to be installed:

- Exhaust gas heat exchanger

- Cloud condenser

- Compact heat exchanger

- Puffer storage

- c) Possible energy savings reachable by those measures

- Savings are possible in energy consumption and in CO2 emission.

- d) Economic evaluations

- This type of heating system requires high investment costs, but different regional development programs already exist for supporting the companies in financial aspects. Considering the total annual costs the application of a wood pellets heating system makes sense because it offers the advantage of annual costs savings especially when the crude oil prize is high.

- Reference: Kötter, A.: Abschlussbericht "Ökobäckerei mit ganzheitlichem Konzept", 2005

- c) Changes in the heat supply system

- Shift from fossil fuels to biomass, e.g. wood pellets

- a) Description of the technology

- Wood pellets are used as an energy source and are are manufactured according to standardized quality standards. The decision in favor of wood pellets compared to wood chips was due to the defined quality standards and accurate calibration taken. This ensures a trouble-free automatic feeding to the oven burner and the pellet boiler.

- b) Description of suitable energy supply systems

- In the case of a wood pellet heating system a wood pellet silo and a wood pellet stove have to be installed. Furthermore several appliances for ash recovery are required.

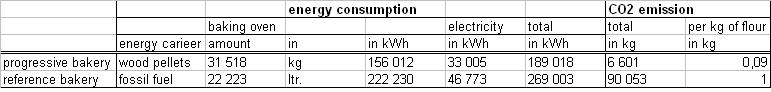

- c) Possible energy savings reachable by those measures

- Savings are possible in energy consumption and in CO2 emission.

- Table 3: comparison of bakeries in energy consumption

- d) Economic evaluations

- This type of heating system requires high investment costs, but different regional development programs already exist for supporting the companies in financial aspects. Considering the total annual costs the application of a wood pellets heating system makes sense because it offers the advantage of annual costs savings especially when the crude oil prize is high.

- Reference: Kötter, A.: Abschlussbericht "Ökobäckerei mit ganzheitlichem Konzept", 2005

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production