Difference between revisions of "Information about cake"

m (Protected "Information about cake" [edit=autoconfirmed:move=autoconfirmed]) |

m (Changed protection level for "Information about cake" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

(No difference)

| |

Revision as of 13:33, 20 February 2013

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of cake production

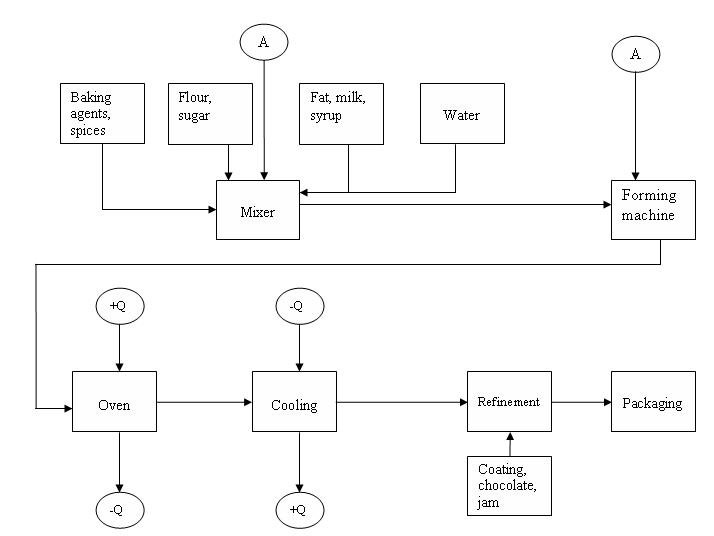

Figure 1: Production of cakes. Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

- 2. Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

The main ingredients are wheat flour, fat, eggs, sugar, milk powder, water flavouring and raising agents.

Cakes are generally made by using two different methods:

- Sugar batter method: fat and sugar are creamed together, eggs are added in stages

- Flour batter method: fat and flour are blended together. Eggs and sugar are whisked are whisked together and the mixture is blended into the flour-fat- mix in stages. Then the liquid are added in small amounts.

In continuous mixing systems the ingredients are given a preliminary mix and are then fed in a continuous even stream. But more often used is “all in” high speed mixing. All ingredients (except fruit) are added, and then fruit is added in short bursts.

The batter is put into oil- sprayed trays. After baking the cakes are removed from the tins and are cooled.

- 3. Temperature ranges and other parameters

- 4. Benchmark data

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- c) Changes in the heat supply system

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production