Information about wine & beverages production

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Contents

Wine production

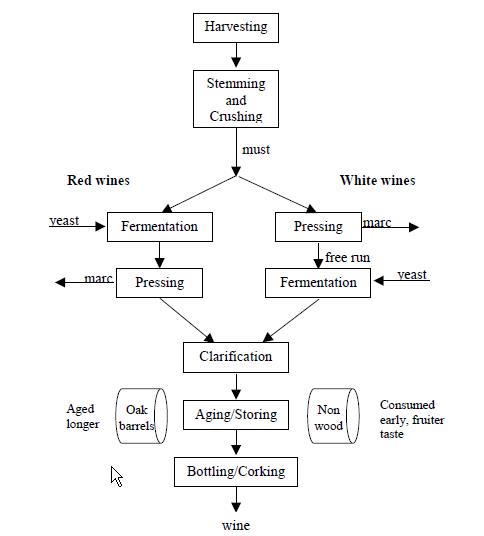

There are numerous variations in winemaking technologies, mainly due to the type of wine to be produced. The main production stages are (BREF FDM 2006):

Reception

When grapes are received at the winery, they are sorted by variety, quality and quantity. Containers are emptied directly into either crushing or transport equipment. Emptied containers are cleaned. The cleaning water is drained.

Grape crushing and destemming

Grape crushing or mashing takes place in grape mills. If maceration is intended, the mash can be stored in mash containers. To prevent the mash from oxidation H2SO3 is added. The decision as to whether destemming of the white grapes is necessary before the grape mash is made depends on the variety and ripeness of the grapes as well as on the further processing of the mash.

Pressing

For white wine, the mash is transported to the wine press. The resulting unfermented grape juice is referred to as must. Sulphur dioxide is often added at this stage at the rate of 100 – 150 mg/l to suppress undesirable micro-organisms, e.g. grape skins are often covered with bacteria and moulds, as well as the yeasts used in the process. The solid residues, e.g. pomace and marc, are then separated. For red wine, when the fermentation process is finished, i.e. when the sugar levels are under 0.1 %, the wine is taken from the bottom of the tank and the marcs are transferred to the wine press to extract the remaining wine.

Fining

The fining agents used in winemaking are gelatine, casein, isinglass, chitin, albumin or egg white; natural mineral adsorbents, e.g. bentonite, diatomaceous earth or silica; and synthetic polymers, e.g. PVPP. It is reported that sediments from clarification are separated by centrifugation or filtration. This removes unwanted particles left in suspension.

Fermentation

Alcoholic fermentation takes place in large stainless steel fermentation reactors or vats with or without the addition of pre-cultivated yeast, e.g. usually Saccharomyces cerevisiae, and under rigorous temperature control. White wine is fermented after marc separation, while red wine is fermented together with grape marcs. Red wine, and sometimes white wine as well, goes through a second malolactic fermentation. This is a bacterial fermentation that converts the malic acid into lactic acid.

Ageing

After fermentation, wine is cooled to 4 – 5 ºC and transferred to barrels or wooden vats made of oak for ageing. This allows the wine to stabilise and to develop softer tannins and complex flavours. Lees are separated from the wine every 3 to 4 months. The barrels are then washed and refilled.

Cold stabilisation

Cold stabilisation involves rapid cooling of the wine to near freezing temperatures to precipitate tartrate crystals which are undesirable in the bottled wine, whether present in the cork or in the bottom of the bottle. Tartrate precipitates in the tanks and is removed with an alkaline cleaning solution of 10 % caustic soda.

Bottling

Before bottling, wine is passed through a filtration system to remove remaining solid and insoluble turbid compounds. Bottling involves the microbial stabilisation of the wine and preserves the wine from important changes in taste and chemical composition. BREF FDM 2006

Simplified Schematic Presentation of the Winemaking Process (University of California, 2005)

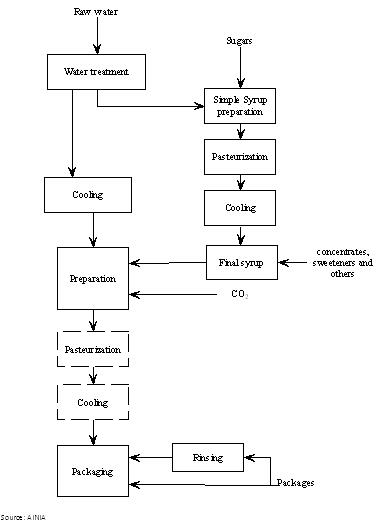

Soft drink production

Soft drinks can be categorised into two main types, i.e. carbonated and still. Soft drinks include spring waters, fruit and juice based drinks such as cordials, squashes and barley waters; flavoured drinks such as ginger beer; tonic waters and lemonades, as well as infusions such as tea and coffee.

Ingredients typically found in most soft drinks include water, sweetener, acid and flavourings. Optional ingredients include fruit, carbon dioxide, preservatives and colour. Water is the main ingredient of all soft drinks and, as such, the quality of the water, in terms of its microbiological loading and other parameters which affect the final sensory qualities of the drink, are of paramount importance.

Most soft drinks are sweetened with natural sweeteners such as sugar and sugar syrups, and/or intense sweeteners such as saccharin and aspartame. Flavourings used in manufacture are often derived from highly concentrated liquid mixtures of plant extracts such as fruit, flowers, seeds, leaves, bark and root. Alternatively, they may be synthetic. All sparkling soft drinks require the addition of carbon dioxide. This may be sourced as a coproduct from the petroleum, beer and whisky industries, or produced on site. The preservation of soft drinks can be achieved by a number of techniques including heating, chemical preservation and filtration. These methods, in combination with low pH, prevent microbiological spoilage.

The basic processes for the manufacture of soft drinks involve the mixing of ingredients in the syrup room, followed by the addition of water that has been subjected to various water treatments. The mixture may be heat processed or chemically preserved at this stage. The product is carbonated if required. Alternatively, after the syrup and water are combined, the product may be filled into packaging and in-pack heat processed. Syrups may require filtration or homogenisation and may be pasteurised. Most packaging is cleaned prior to filling, either by rinsing with water, possibly containing rinsing aids, or by air blasting.

Flow-chart process for soft drinks products

Energy consumption in Wine/beverage sector

Soft drink sector

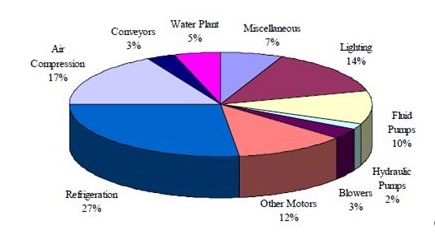

Soft drink manufacturing facilities have significant electricity and thermal energy usage (Ganji, 2002). The energy use ratio for soft drink bottling in production facilities is typically in the range of 0.4-0.6 MJ per litre of produced beverage (UNESDA, 2009).

Major power demanding operations in a large soft drink manufacturing plant are refrigeration (27%) and compressed air (17%) (Ganji, 2002).

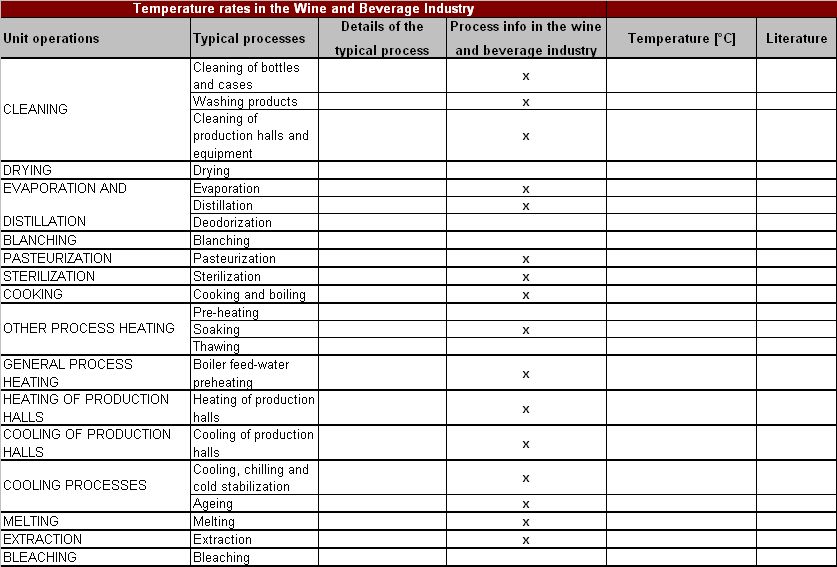

Significant levels of refrigeration and heating are needed in the carbonation and bottling/canning processes. Refrigeration is required for lowering the drink mixture to a temperature low enough to absorb the necessary amount of carbon dioxide. Strategies for increase these set temperature are being applied to reduce energy consumption in refrigeration. Compressed air is mainly used in packaging activities as in blowing and drying PET bottles (ANFABRA, 2012). Companies can reduce energy consumption in compressed air by implementing best practices as prevent air leakages, good maintenance, improving intake air quality, monitoring or improving design (Carbon Trust, 2012). Energy efficiency in compressed air can be improved by using blowers instead of compressors in those use points where a low pressure flow of air is required, as in drying packages stage.

Other activities demanding electricity are: lighting, blowers, and pumps for pumping water and product, hydraulic pumps for palletizers. Thermal energy is used mainly in pasteurization, packaging sterilization (when required), cleaning and disinfection or warming the containers to avoid condensation.

Source: Ganji et al; 2002

Wine sector

Much of the electricity used in winemaking goes to refrigeration for fermentation cooling, cold stabilization and cold storage. The rest is mainly used for compressed air, hot water or electricity for pumping and bottling line motors, though compressed air demand is highly variable from winery to winery. Enclosed areas for storage and processes also require lighting and many are cooled. Hot water is needed for cleaning barrels and equipment and for heating red wine ferments and yeast generator tanks. Other non-process use power is required for buildings and other miscellaneous administrative or maintenance applications. (University of California, 2005)

Benchmarks

Specific energy use will vary for each winery, as will the distribution of energy use, depending on the type of products made, process choices, and efficiency of the operation (University of California, 2005)

Sources

- ANFABRA (Asociación Nacional de Fabricantes de Bebidas Refrescantes Analcohólicas), 2013. Proceso de fabricación. Available at: http://www.refrescantes.es/page_view.php?PageID=ESP_Sector&ContentID=62 [Accessed 30 April 2013]

- Carbon Trust. 2012. Compressed air- Opportunities for businesses. Available at http://www.carbontrust.com/media/20267/ctv050_compressed_air.pdf [Last access: December 3rd]

- Ganji A, Hackett B and Chow S. 2002. Energy Conservation Opportunities in Carbonated Soft Drink Canning and Bottling Facilities. Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19.

- UNESDA (Union of European Beverages Associations). 2009. Environmental responsibility. Active innovation. Produced for UNESDA by Zenith International Publishing Ltd www.foodbev.com.

University of California. 2005. BEST Winery Guidebook: Benchmarking and Energy and WaterSavings Tool for the Wine Industry.

- Benchmarks

For benchmark data, check above the sector Products.

- Products