Mevgal (Greece)

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

Back to Cleaning of bottles and cases for milk products

Back to Case studies

- 1. Built example

Built example: A solar system has been built to increase the energy efficiency of the process.

- 2. Industry Sector

Food – Dairy

- 3. Industrial application

Cleaning equipment and preheating of boiler feed-water.

- 4. Process description

- Process flowsheet:

No information is available.

- Processes:

No information is available.

5. Energy flows and temperature ranges

- Main heat supply system and fuel:

No information is available.

- Energy consumption (Sankey):

No information is available.

- Temperature ranges and other parameters:

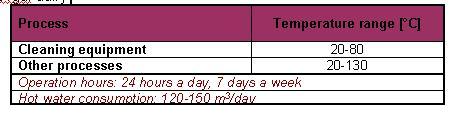

The following table presents the temperature ranges of the process medium and other parameters in the Mevgal dairy:

Table 1: Temperature ranges of the process medium and other parameters in the Mevgal dairy

LITERATURE: Aris Aidonis, CRES (Centre for Renewable Energy Sources)

- 6. Solar Thermal Plant

- Used scheme:

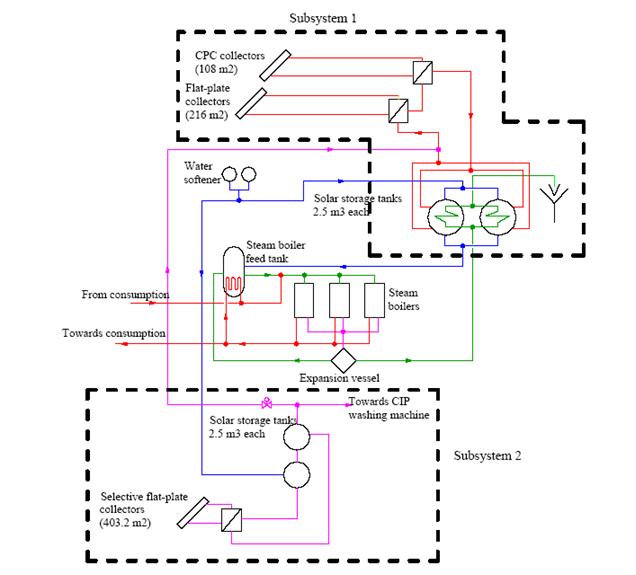

Figure 1: Flowsheet of built solar system in Mevgal dairy LITERATURE: PROCESOL II, ALTENER 4.1030/Z/98-205, Charter 13 - INDUSTRIAL PILOT PLANT

- Description of the main features and components:

The solar system presented in Figure 1 consists of two subsystems:

a) Subsystem 1 depicted in Figure 24 consists of two primary closed circuits with a water/ethylene glycol (20%) mixture. Primary circuit 1 has 216 m2 flat-plate collectors, which transfer their heat to the process water via heat exchanger 1 (94.6 kW capacity) and primary circuit 2 has 108 m2 CPC vacuum tube collectors, which transfer their heat to the process water via heat exchanger 2 (79.1 kW capacity). The heat exchangers are connected in series and the process water first enters heat exchanger 1 and then heat exchanger 2 before entering the two parallel 2.5 m3 storage tanks which are heated additionally by the steam boiler blow-down water. The solar collectors are located on the roof of the boiler room.

b) Subsystem 2 depicted in Figure 25 consists of a primary closed circuit with a water/ethylene glycol (20%) mixture. Primary circuit 3 has 403.2 m2 selective flat-plate collectors, which transfer their heat to the process water via heat exchanger 3 (209.3 kW capacity). The hot water generated in the heat exchanger is fed to two in-series 2.5 m3 water storage tanks and is then fed to the washing machine of the plant. When the washing machine is not in operation, the hot water is bypassed and fed to heat exchanger 1 of subsystem 1. The solar collectors are located on the roof of the cheese factory of the plant.

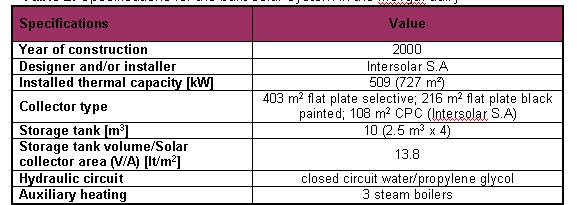

The following table presents the specifications of the built solar system in the Mevgal dairy:

Table 2: Specifications for the built solar system in the Mevgal dairy

LITERATURE: Aris Aidonis, CRES (Centre for Renewable Energy Sources)

- Performance of the built solar system:

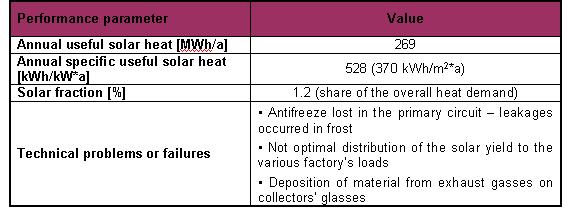

The following table presents the performance parameters of the built solar system in the Mevgal dairy:

Table 3: Performance parameters of the built solar system in the Mevgal dairy

LITERATURE: Aris Aidonis, CRES (Centre for Renewable Energy Sources)

- Pictures of the built solar system:

LITERATURE: Aris Aidonis, CRES (Centre for Renewable Energy Sources)

- 7. Energy savings

- Pinch analysis results:

No information is available.

- Energy savings:

No information is available.

- 8. Economic evaluation

- Economic parameters of the built solar system:

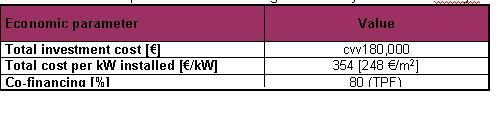

The following table presents the economic parameters of the built solar system in the Mevgal dairy:

Table 4: Economic parameters for building the solar system in the Mevgal dairy

LITERATURE: Aris Aidonis, CRES (Centre for Renewable Energy Sources)

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

Back to Cleaning of bottles and cases for milk products

Back to Case studies