Molluscs

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about fish aroma

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of the production line

No information is available.

- 2. Description of techniques, methods and equipment

- (BAT in the Food, Drink and Milk Industries, June 2005)

The types of molluscs processed and consumed in Europe mainly comprise cephalopods (cuttlefish, squid, octopus) and bivalves (oyster, mussel, clam and scallop). Processing includes freezing, canning and pickling. After cooking and shell removal, washing is often carried out by blowing air at the bottom of washing tank to agitate the meat, while the grit and shell particles settle down. Some molluscs, such as oysters or mussels are pickled with vinegar and spices. Here, the meat is dipped in 3 % salt brine, drained and covered for three days with a 3 % vinegar solution containing 3 % salt. They are then drained, packed and covered with spiced vinegar.

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data

- (BAT in the Food, Drink and Milk Industries, June 2005)

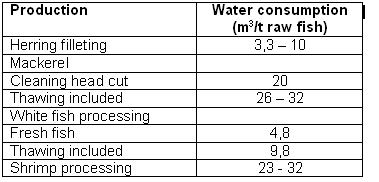

To meet quality and hygiene standards, the fish sector used high quantities of water. It is mainly consumed for cleaning operations and washing, and transportation of fish. Fish canning and fish filleting consume large quantities of water, e.g. to clean and lubricate the filleting machinery. Typical figures for fresh water consumption are for thawing, about 1 m3/t fish; for filleting 5-11 m3/t fish, and for canning, 15 m3/t fish. Water is used for transporting fish and viscera, for cleaning the installation and the equipment, for washing raw materials and products, and for thawing. The following table shows the specific water consumption for traditional fish processing:

Table 1: Specific water consumption in Nordic countires

The consumption of energy depends on the installation, the equipment and the fish manufacturing processes that take place. Processes, e.g. canning, that involve heating, cooling, production of ice, drying, evaporation and oil production consume more energy than those that do not, e.g. filleting, where energy consumption is low. On average, filleting consumes 65-87 kWh/t of fish and canning consumes 150-190 kWh/t of fish.

2. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about fish aroma