Plating chromium in metal industry

From Efficiency Finder

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

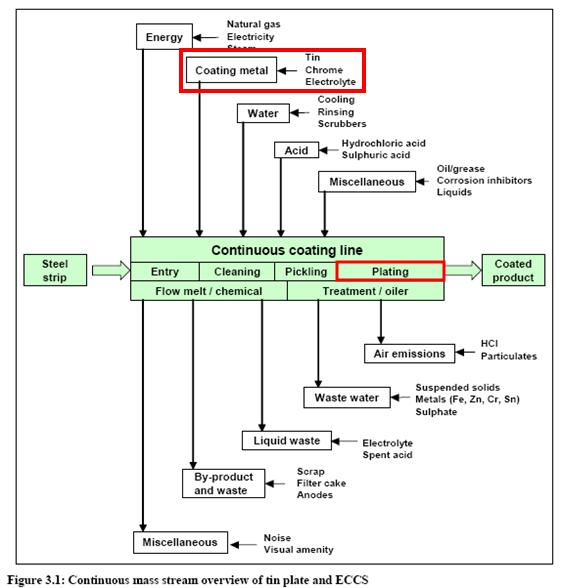

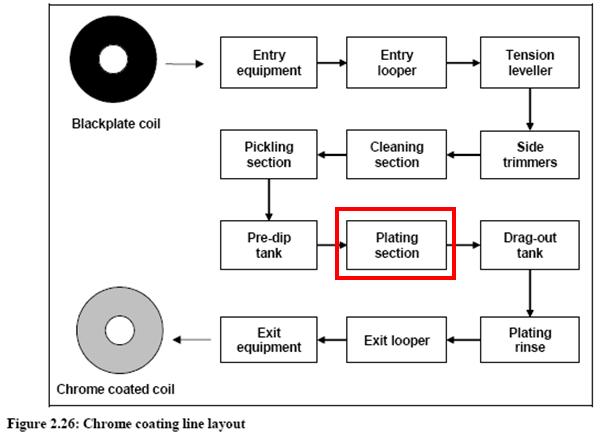

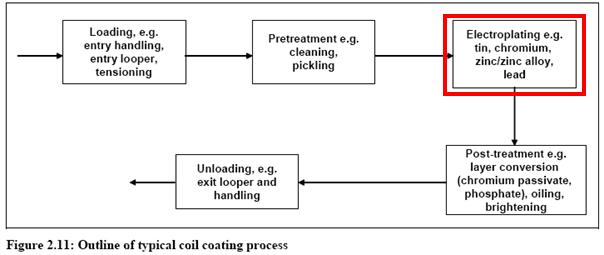

- Plating chromium flowsheet

Literature: BAT for the Surface Treatment of Metals and Plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Bright hexavalent chromium plating | Chromic acids, sulpahtes as the primary catalyst such as fluoride ions | Chromic acids: 80-400 g/l; sulphate: 0,8-5 g/l; fluoride ions: <2% of the concentartion of the chromic acid | BAT for the surface treatment of metals and plastics, August 2006 | ||||

| Bright chromium plating (decoration) | 20-45 | 2-13 min | Trivalent chromium | 20 g/l | |||

| Bright trivalent chromium electroplating | |||||||

| Black chromium plating | Hexavalent chromium acid; catalysts (nitrates, fluorides) | Hexavalent chromium acid electrolytes: 350-520 g/l | |||||

| Hard chromium plating | Chromium acid and one the following catalysts: sulpahte ions, mixed sulpahte and fluoride ions, pre-prepared proprietary fluoride- free | Chromic acid: 180-350 g/l; sulpahte ions: 1,8-6 g/l; mixed sulphate and fluoride ions: <2% of the content of the chromic acid; pre-prepared proprietary fluoride-free: <2% of the content of the chromic acid |

- Energy losses from the surface area of heated process solutions

Image:Energy losses from the surface area of heated process solutions.jpg

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005