Difference between revisions of "Plating zinc and zinc alloy in metal industry"

From Efficiency Finder

(New page: Back to EFFICIENCY FINDER FOR METAL INDUSTRY *;Description of the process *;Plating zinc and zinc alloy ...) |

m (Changed protection level for "Plating zinc and zinc alloy in metal industry" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 33: | Line 33: | ||

| align="center" style="background:#2266CC;"|'''Literature''' | | align="center" style="background:#2266CC;"|'''Literature''' | ||

|- | |- | ||

| − | | style="background:#AACCEE;"| | + | | style="background:#AACCEE;"| Plating with alcine cyanide zinc solutions|| align="center"| || align="center"| || align=”center”| || align=”center”| Zinc oxide, sodium hydroxide, sodium cyanide|| align="center"| Zinc oxide: 10-30 g/l; sodium hydroxide: 80-120 g/l; sodium cyanide: 5-100 g/l|| align="center"| || rowspan="4" align="center"| BAT for the surface treatment of metals and plastics, August 2006 |

|- | |- | ||

| − | | style="background:#AACCEE;"| | + | | style="background:#AACCEE;"| Plating with alkaline cyanide-free zinc solutions|| align="center"| || align="center"| || align=”center”| || align=”center”| Zinc oxide, sodium hydroxide, potassium hydroxide|| align="center"| Zinc oxide: 5-15 g zinc/l; sodium hydroxide or potassium hydroxide: 100-150 g/l; || |

|- | |- | ||

| − | | style="background:#AACCEE;"| | + | | style="background:#AACCEE;"| Plating with acid zinc solutions|| align="center"| || align="center"| || align=”center”| || align=”center”| Alloys: zinc/iron(<1%) from alkaline cyanide-free electrolytes; zinc-cobalt(<3% Co) from acid or cyanide-free electrolytes; zinc-nickel(<15% Ni) from acid (ammonium chloride-based) or cyanide-free electrolytes|| align="center"| || align="center"| |

|} | |} | ||

Latest revision as of 18:41, 13 February 2013

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

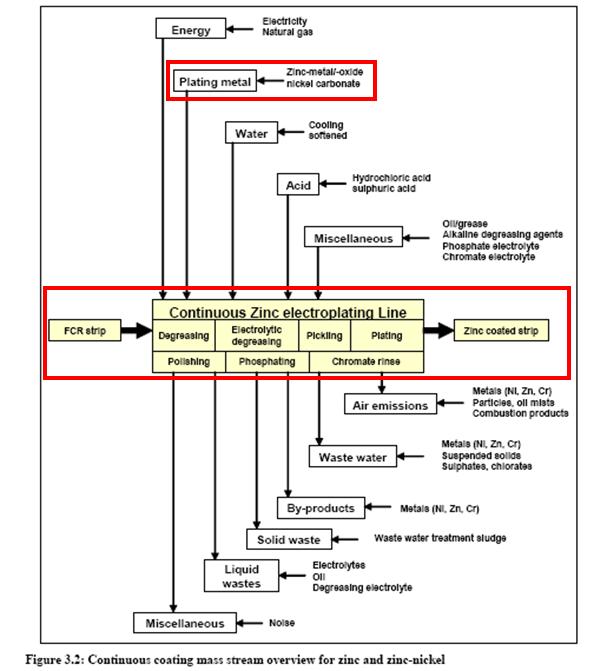

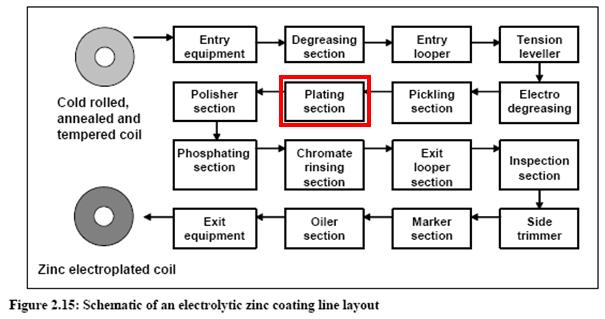

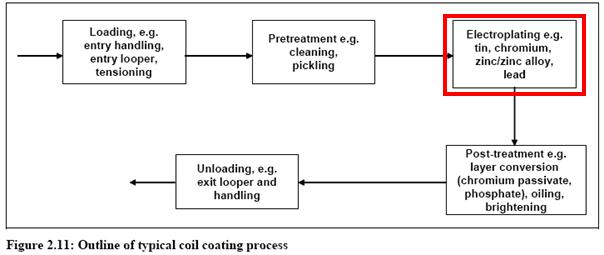

- Plating zinc and zinc alloy flowsheet

Literature: BAT for the Surface Treatment of Metals & Plastics, 2006

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Plating with alcine cyanide zinc solutions | Zinc oxide, sodium hydroxide, sodium cyanide | Zinc oxide: 10-30 g/l; sodium hydroxide: 80-120 g/l; sodium cyanide: 5-100 g/l | BAT for the surface treatment of metals and plastics, August 2006 | ||||

| Plating with alkaline cyanide-free zinc solutions | Zinc oxide, sodium hydroxide, potassium hydroxide | Zinc oxide: 5-15 g zinc/l; sodium hydroxide or potassium hydroxide: 100-150 g/l; | |||||

| Plating with acid zinc solutions | Alloys: zinc/iron(<1%) from alkaline cyanide-free electrolytes; zinc-cobalt(<3% Co) from acid or cyanide-free electrolytes; zinc-nickel(<15% Ni) from acid (ammonium chloride-based) or cyanide-free electrolytes |

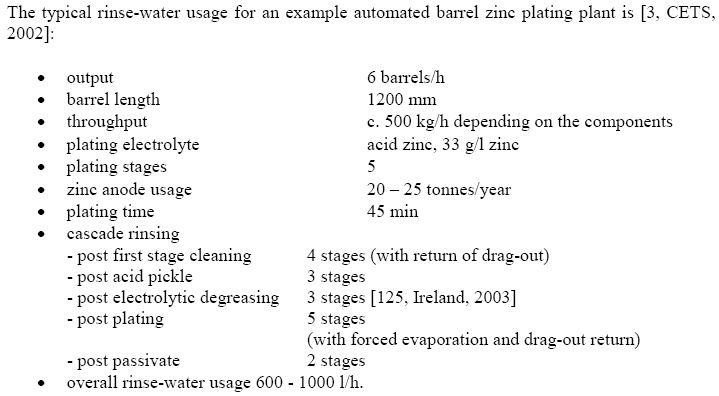

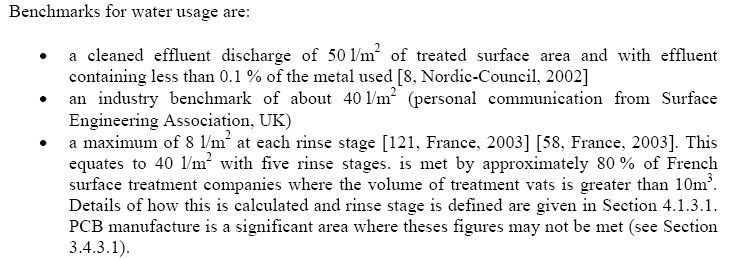

- Plating zinc and zinc alloy

Literature: BAT for the Surface Treatment of Metals & Plastics, 2006

Literature: BAT for the Surface Treatment of Metals & Plastics, 2006

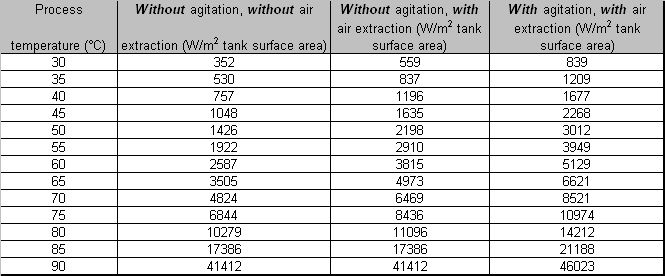

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005

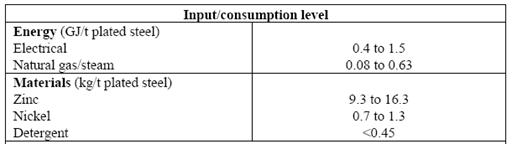

Zinc electroplating:

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005