Pork

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about meat production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet for pig slaughtering

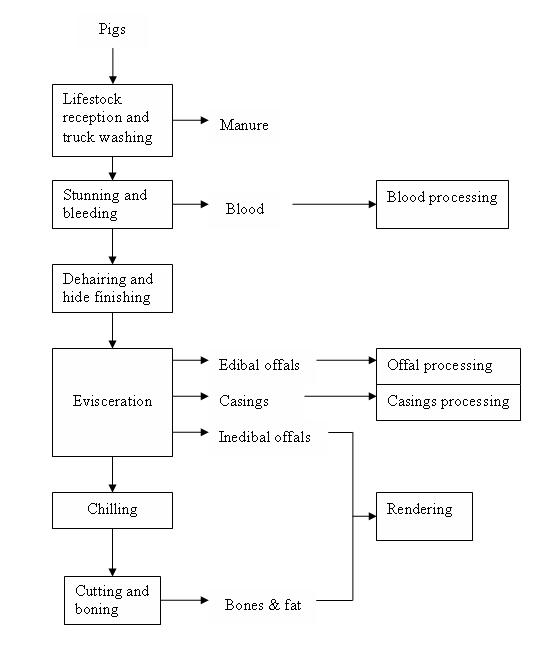

Figure 1: Flowdiagram for slaughtering of pigs

- 2. Description of techniques, methods and equipment

- Prehandling of pigs

Pigs are delivered to the abattoir in trucks, and held for one to two days in holding yards. They are generally fasted for a day to reduce the amount of intestinal contents.

- Stunning and bleeding

Pigs are stunned using an electric shock or by anaesthetising in carbon dioxide, after which they are bled. Bleeding, also referred to as sticking, is carried out using a hollow knife, which directs the blood to a collection trough, from where it is pumped to an agitated tank for further processing.

- Dehairing and finishing

Before being processed further, hair is removed from the pig carcasses, by scalding in hot water followed by scraping. Carcasses are then singed to remove any remaining hair. This process leaves the hide almost white in colour, clean and smooth without any trace of hair.

- Evisceration and splitting

After dehairing and hide finishing, the carcasses pass to the evisceration area, where the stomachs are opened and the viscera removed. The breastbone is split and the plucks (heart, liver and lungs) are loosened and removed. The carcasses are then de-headed and split along the backbone. Finally, the carcasses are chilled rapidly overnight before the subsequent processes of cutting and boning can take place.

- By-products processing

Edible offal components and casings (intestinal tract) are separated from the viscera and sent on for cleaning and further processing, generally in other parts of the plant.

- Rendering

At various stages in the process, inedible by-products such as bone, fat, heads, hair and condemned offal are generated. These materials are sent to a rendering plant either on site or off site for rendering into feed materials and tallow.

- 3. Temperature ranges and other parameters

- 4. Benchmark data

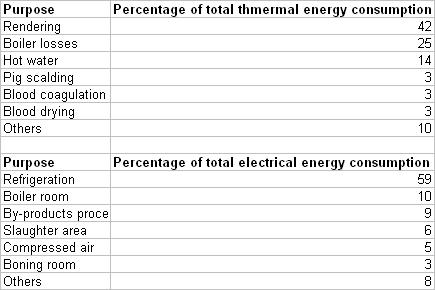

Table 1: Breakdown of thermal/electrical energy consumption

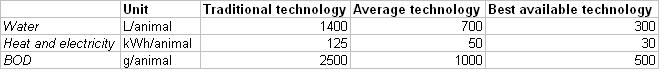

Table 1: Benachmark for pig abattoirs (90 kg pigs)

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- c) Changes in the heat supply system

Reference: Cleaner Production Assessment in Meat Processing, report prepared by COWI Consulting engineers and planning agents AS, demark for UNEP and Danish Enviromental Protection Agency, 2000