Printing in textile industry

Back to EFFICIENCY FINDER FOR TEXTILE INDUSTRY

1. OBJECTIVE

Printing, like dyeing, is a process for application of colour to a substrate. However, instead of colouring the whole substrate (cloth, carpet or yarn) as in dyeing, print colour is applied only to defined areas to obtain the desired pattern. This involves different techniques and different machinery with respect to dyeing, but the physical and chemical processes that take place between the dye and the fibre are analogous to dyeing. There is a lot of water consumed by this process. For example, it takes 100 litres of water just to clean one screen or squeegee, and on average about 250 litres of water to process one kg of printed textile (transfer printing excluded). (BAT for the Textiles Industry, July 2003)

2. FIELD OF APPLICATION

Printing with pigments: for almost all fibres, especially for Cellulose fibres (BAT for the Textiles Industry, July 2003).

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

A typical printing process involves the following steps (BAT for the Textiles Industry, July 2003):

- colour paste preparation: when printing textiles, the dye or pigment is not in an aqueous liquor, instead, it is usually finely dispersed in a printing paste, in high concentration

- printing; the dye or pigment paste is applied to the substrate using different techniques, which are discussed below

- fixation: immediately after printing, the fabric is dried and then the prints are fixed mainly with steam or hot air (for pigments); note that intermediate drying is not carried out when printing carpets (too much would be needed for removing the highly viscous liquor)

- after-treatment: this final operation consists in washing and drying the fabric (it is not necessary when printing with pigments or with other particular techniques such as transfer printing)

When describing the different printing techniques, a distinction should be made between printing with pigments, which have no affinity for the fibre, and printing with dyes (reactive, vat, disperse, etc.) (BAT for the Textiles Industry, July 2003).

- Printing with pigments: (BAT for the Textiles Industry, July 2003)

Pigment printing has gained much importance today and for some fibres (e.g. cellulose fibres) is by far the most commonly applied technique. Pigments can be used on almost all types of textile substrates and, thanks to increased performance of modern auxiliaries, it is now possible to obtain high-quality printing using this technique.

Pigment printing pastes contain a thickening agent, a binder and, if necessary, other auxiliaries such as fixing agents, plasticizers, defoamers, etc.

White spirit-based emulsions, used in the past as thickening systems, are used only occasionally today (mainly half-emulsion thickeners).

After applying the printing paste, the fabric is dried and then the pigment is normally fixed with hot air (depending on the type of binder in the formulation, fixation can also be achieved by storage at 20°C for a few days). The advantage of pigment printing is that the process can be done without subsequent washing (which, in turn, is needed for most of the other printing techniques.

- Printing with dyes: (BAT for the Textiles Industry, July 2003)

a) Printing paste preparation

The process traditionally starts with the preparation of the paste. Compared to pigment printing, the composition of the pastes is more complex and variable, being determined not by the dye used, but by the printing technique, the substrate, the application and the fixation methods applied.

Apart from the dye, printing pastes contain a thickening agent and various other auxiliaries, which can be classified according to their function as follows:

- oxidising agents (e.g. m-nitrobenzenesulphonate, sodium chlorate, hydrogen peroxide)

- reducing agents (e.g. sodium dithionite, formaldehyde sulphoxylates, thiourea dioxide, tin(II) chloride)

- discharging agents for discharge printing (e.g. anthraquinone)

- substances with a hydrotropic effect, like urea

- dye solubilisers, which are polar organic solvents like glycerine, ethylene glycol, butyl glycol, thiodiglycol, etc.

- resists for reactive resist printing (e.g. sulphonated alkanes)

- defoamers (e.g. silicon compounds, organic and inorganic esters, aliphatic esters, etc.)

All the necessary ingredients are metered (dosed) and mixed together in a mixing station. Since between 5 and 10 different printing pastes are usually necessary to print a single pattern (in some cases up to 20 different pastes are applied), in order to reduce losses, due to incorrect measurement, the preparation of the pastes is done in automatic stations. In modern plants, with the help of special devices, the exact amount of printing paste required is determined and prepared in continuous mode for each printing position, thus reducing leftovers at the end of the run.

It is common practice in many printing houses to filter the printing pastes before application, using for example a filter cloth. This operation is especially important for thickeners to prevent free particles from blocking the openings of the screens.

b) Printing (paste application) After preparation, the paste is applied to specific areas of the textile using one of the following techniques:

- direct printing (which also includes digital and transfer printing)

- discharge printing

- resist printing

In the case of direct printing the dye is applied to specific areas of a pretreated textile substrate, which can be white or pre-dyed (in light colours).

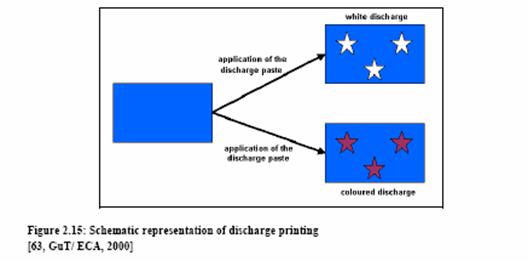

It is possible to speak of discharge printing, if in the fixation process that follows the application of the printing paste there is local destruction of a dye applied previously. If the etched (discharge), previously dyed area becomes white, then the process is called white discharge. If, on the contrary, a coloured pattern has to be obtained in the etched area after the destruction of the previously applied dye, then the process is called coloured discharge. In this case the printing paste must contain a reduction-resistant dye along with the chemicals needed to destroy the previous one. As a result the pre-dyed background is destroyed according to a pattern and the dye, which is resistant to reduction, takes its place.

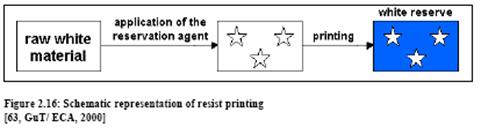

In the case of resist printing, a special printing paste (called “resist”) is printed onto certain areas of the fabric to prevent dye fixation. In the case of physical resist, the material is printed with a difficult-to-wet resin that inhibits the penetration of a dye applied in a second stage. On the other hand, with a chemical resin, dye fixation is prevented by a chemical reaction. Depending on the way the process is carried out, one can speak of pre-printing, intermediate or over-printing resists. One common procedure is the wet-on-wet process in which the resin paste is initially printed, then the material is overprinted with full cover screen and finally fixed and washed. Over-printing resists can be applied only if the dye, already present in the previously dyed and dried fabric, is still in its unfixed form, as in the case of developing dyes.

The difference between transfer printing and the techniques described earlier is that with this technique the surface of the fabric is not directly printed. Instead, the pattern is first created on an intermediate carrier (e.g. paper) using selected disperse dyes and then it is transferred from there to the fabric. The dye is usually fixed by placing the printed paper in contact with the fabric into a thermal pressure system. Under the influence of the heat the dye sublimates and then diffuses from the carrier into the fibre of the textile substrate. There is no need for further treatment such as steaming, washing, etc. This technique is applied for polyester, polyamide and some acrylic fibres, sing selected disperse dyestuffs according to the specific type of fibre.

c) Fixation

After printing, the fabric is dried. Water evaporation leads to an increase in dye concentration and at the same time prevents the colours from smearing when the fabric is transported over the guide rollers. At this stage the dye is not yet fixed.

The aim of the subsequent fixation step is to transport as much as possible of the dye, which is retained by the thickener, into the fibres. This is especially important with dyes, such as vat dyes, for example, that are printed in the insoluble form and are converted into the corresponding soluble state only after reaction with the reducing agents during the fixation process.

Fixation is usually carried out with steam. Water vapour condenses on the printed material, swells up the thickener, heats the print and provides the necessary transport medium for the diffusion of the dye. The distribution of the dye between fibre and thickener is an important factor in determining the fixation degree of the dye, which is called the “retaining power” of the thickener. The thickener, in fact, is often composed of polysaccharides and therefore competes with cellulose in retaining the dye. This is the main reason why the fixation rate of a given dye is 10% lower in printing than in dyeing.

d) After-treatment

The last step of the printing process consists in washing and drying the fabric. When printing with insoluble dyes such as vat dyes this operation also serves as a means to re-convert the dye to the original oxidised state, In this case, after an initial rinsing with cold water, the printed material is treated with hydrogen peroxide. The process is completed with a soap treatment with sodium carbonate at the boiling temperature.

As already explained, washing is not necessary with pigment printing and transfer printing. This holds for any dyeing/printing system where thickeners are not needed and where the dyestuff is (nearly) completely fixed (e.g. printing carpet tiles with digital jet printing techniques).

e) Ancillary operations

At the end of each batch and at each colour change various cleaning operations are carried out:

- the rubber belt, to which the fabric is glued during printing, is cleaned in continuous mode with water to remove excess adhesive and printing paste. Come machines are equipped with water re-circulation systems

- the printing gears (all systems responsible for feeding and applying the pate to the substrate) are cleaned by first removing as much as possible of the paste residues and then rinsing with water. In some companies the paste residues are directed back to the appropriate printing paste batch containers for re-use

- the remaining paste in the containers, in which the paste is prepared (paste vats), are in general previously cleaned up by the means of sucking systems before being washed out with water. The residual printing collected in this manner is then disposed of

For further information on printing technologies click here.

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

- Reduction in water consumption: (BAT for the Textiles Industry, July 2003)

For information on water saving measures see “Finishing”.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.