Process Info: Blanching in vegetable production

Back to Blanching in vegetable production

I. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

- Blanching for fruits and vegetables:

(BAT for Food, Drink and Milk Industries, June 2005) Blanching is used in most vegetables destined for canning, freezing or drying. Typically, it is carried out using hot water or steam. If the product is to be frozen, blanching is followed by water or air cooling. Belt blanching with water cooling consumed approximately half the energy of belt blanching with air cooling or drum blanching with countercurrent water cooling.

- Steam blanching with air cooling:

(BAT for Food, Drink and Milk Industries, June 2005) Steam blanching is a continuous process where the food is moved on a long perforated conveyor belt. During preheating, the food is sprinkled with water from above and sprayed by water from below. The preheating water is maintained at 60°C using steam. During the blanching step, the food is further heated by direct steam injection from below. To minimize water and energy consumption, the steam is recycled and the process takes place in sealed equipment, designed to minimize steam consumption. Finally, the food is cooled with air using heavy duty fans. He air is cooled further, to a lower temperature, by spraying water into the airflow. This water prevents the food from drying. If necessary, the food can be further cooled down with water in the last cooling compartment. Re-using this cooling water in the pre-heating section is not useful, as the water does not hold much energy. Air cooling is less energy efficient than water cooling as the heat cannot be re-used and the fans for blowing the air across the food have high energy consumption. This process results in lower water consumption and waste water volume, compared to the other blanching techniques. Additionally, it results in reduced energy consumption compared to belt blanching with air cooling.

The optimal temperature and time of blanching depend on the type of food and the size of the pieces being blanched. Typical blanching conditions are 65-95°C, for one minute or more.

The energy efficiency can depend on the method of retaining the steam pressure. Food can enter and leave the blancher through rotary valves and seals to reduce steam losses and increase energy efficiency, or steam can be re-used by passing it through venturi valves. Using a combination of hydrostatic and venturi valves can improve the efficiency number.

Steam blanchers reportedly lead to smaller losses of water soluble components and nutrients, but blanching can be uneven if the food is piled too high on the conveyor or if spots of the product have touched each other they may not be blanched.

- Belt blanching with water cooling:

(BAT for Food, Drink and Milk Industries, June 2005) This is a continuous process where the food is moved on one long perforated conveyor belt. The food is preheated with water sprinkled from above and sprayed from below, flowing countercurrently with the food. The temperature of the preheating water is maintained at 60°C using steam. The cooled preheating water can be re-used in other processes, e.g. washing and cutting and pre-rinsing of, e.g. freezing tunnels. In the blanching section, the food is also sprinkled with water from above and sprayed by water from below. For this step, the water temperature is maintained at, e.g. 80-95°C, by steam injection. Finally, the food is cooled with water. Cooling is undertaken in a series of different compartments. In each compartment, water is sprayed over and under the food. Fresh cooling water at, e.g. 2-15°C, enters the last compartment of the cooling section and is re-used in the preceding compartments. The water fro mthe first compartment of the cooling section, i.e. immediately after blanching, which is warm, is re-used in the preheating section, leading to heat recovery and a reduction in water consumption. If the oldest water available is used for cooling, this also reduces energy consumption, for both the cooling step after blanching and if the food is destined for low temperature storage or processing, e.g. freezing. The optimal temperature and time of blanching depend on the kind and size of food.

This process results in lowest energy consumption comparing to all other blanching techniques and reduced water consumption compared to the drum blancher with countercurrent water cooling. The reason for the high energy efficiency of belt blanching with water cooling is that the heat released by the cooling of the food on the cooling zone is used to preheat the vegetables before blanching. Also, the water consumption is minimized by re-using it within the cooling compartments and for preheating.

- Belt blanching with air cooling:

(BAT for Food, Drink and Milk Industries, June 2005) This is a continuous process where the food is moved along on one long perforated conveyor belt. The food is preheated with water sprinkled from above and sprayed from below, flowing countercurrently with the food. The preheating water is maintained at 60°C using steam. The cooled preheating water can be re-used in other processes, e.g. washing and cutting processes and pre-rinsing of, e.g. freezing tunnels. In the blanching section, the food is sprinkled with water from above and sprayed by water from below. The water temperature is maintained at, e.g. 80-95°C, by steam injection. The blanched food is cooled with air using heavy duty fans. The air is cooled further, to a lower temperature, by spraying water into the airflow. This water prevents the food from drying. If necessary, the food can be further cooled down with water in the last cooling compartment. Re-using this cooling water in the preheating section is not useful, as the water does not hold much energy. This technique is less energy efficient, because with air cooling the heat cannot be re-used and the fans for blowing the air across the food have high energy consumption. The optimal temperature and time of blanching depend on the kind and size of food.

- Drum blancher with countercurrent water cooling:

(BAT for Food, Drink and Milk Industries, June 2005) This is a batch process where the food enters the system via a trough and a rotating screw. The water for the blancher is heated by steam injection. The food leaves the system via a perforated paddle. Next, the product is cooled using water running countercurrently to the food. The heated cooling water can be re-used in other processes, e.g. to simultaneously preheat the fresh food and transport it to the drum blancher.

This process results in lower energy consumption compared to belt blanching with air cooling and steam blanching with air cooling.

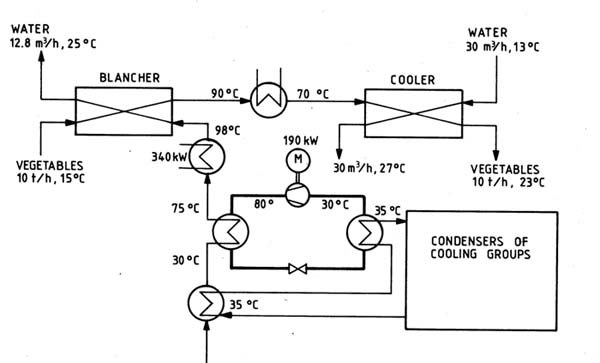

- Blanching process line for vegetables:

The blanching is an important step in the production of vegetables. The process line of blanching for vegetables is presented below:

Figure 1: Blanching line for vegetables

II. NEW TECHNOLOGIES:

- a) Changes in the process

- Microwave blanching

(BAT for Food, Drink and Milk Industries, June 2005) (see also “Competitive technologies and energy saving potentials” in Blanching for the Food sector)

- a) Description of the technology:

- Microwave blanching is used in Europe and Japan. It uses microwave energy to increase the temperature of the heating items. It can eliminate waste water production comparing to conventional water and steam blanching.

- b) Description of suitable energy supply systems:

- No information is available.

- c) Possible energy savings reachable by those measures:

- No information available.

- d) Economic evaluations:

- No information available.

- b) Changes in the energy distribution system

- Heat recovery from the cooling system of the blanching process: (BAT in the Food, Drink and Milk Industries, June 2005)

- a) Description of the technology:

- The final stage in the process of blanching includes a cooling system for the food stream. The water from the first compartment of the cooing section which is warm is re-used in the preheating section, leading to heat recovery and a reduction in water consumption.

- b) Description of suitable energy supply systems:

- No information is available.

- c) Possible energy savings reachable by those measures:

- No information is available.

- d) Economic evaluations:

- No information is available.

- Re-use of cool steams of the process: (BAT in the Food, Drink and Milk Industries, June 2005)

- a) Description of the technology:

- If the coldest water available is used for cooling, this also reduces the energy consumption for both the cooling step after blanching and if the food is destined for low temperature storage or processing, e.g. freezing. Water from cooling cans and jars in fruit and vegetable preservation can be re-used to heat cold water for use in blanching.

- b) Description of suitable energy supply systems:

- No information is available.

- c) Possible energy savings reachable by those measures:

- No information is available.

- d) Economic evaluations:

- No information is available.

- c) Changes in the heat supply system

No information is available.