Sealing following anodizing in surface industry

From Efficiency Finder

Revision as of 12:31, 1 December 2010 by Breka (Talk | contribs) (New page: Back to EFFICIENCY FINDER FOR METAL INDUSTRY *;Description of the process *;Sealing following anodizing ...)

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

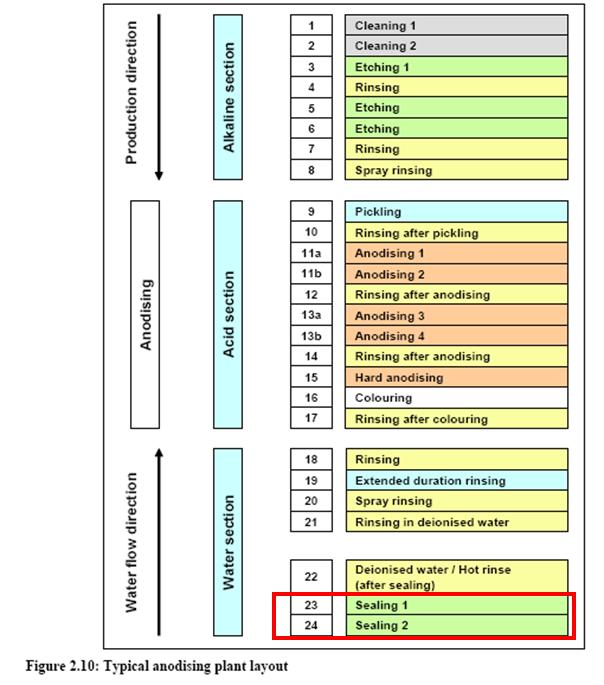

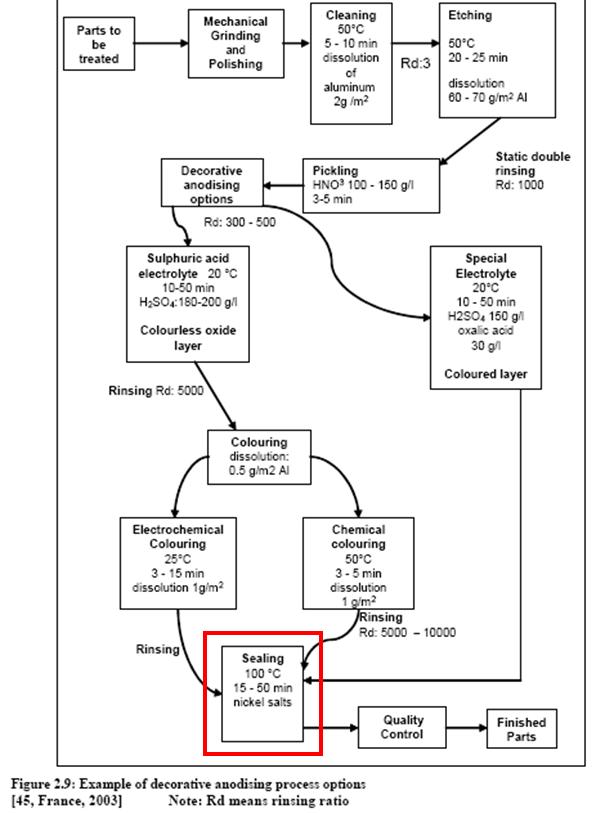

- Sealing following anodizing flowsheet

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Hot sealing | 95-96 | deionized water | 3 min/μm thickness | BAT for the surface treatment of metals and plastics, August 2006 | |||

| steam | Chlorinated hydrocarbones (CHC), hydrcarbones | ||||||

| Cold sealing | 60 | shorter process times | Fluorite or silicate nickel salts | ||||

| 25-35 |

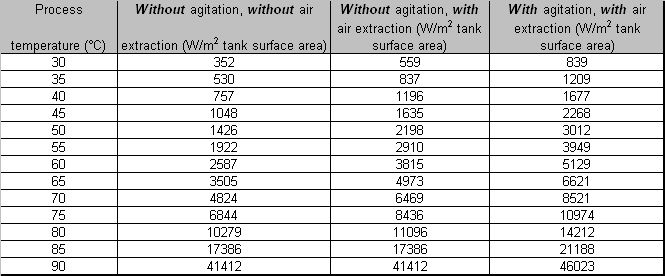

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005