Soft drinks

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about wine & beverages production

1. GENERAL DESCRIPTION:

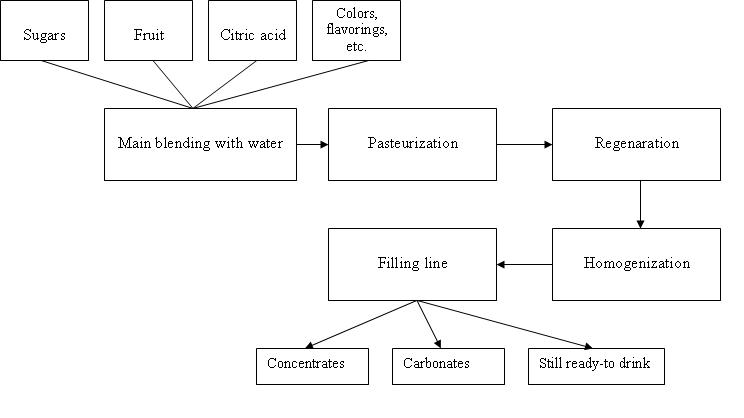

- 1. General Flowsheet of soft drink production

Figure 1: Flowsheet of soft drink production

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

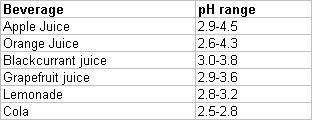

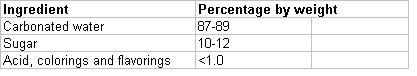

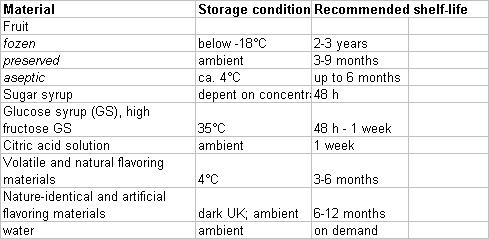

Soft drinks can be categorised into two main types, i.e. carbonated and still. Soft drinks include spring waters, fruit and juice based drinks such as cordials, squashes and barley waters; flavoured drinks such as ginger beer; tonic waters and lemonades, as well as infusions such as tea and coffee. Ingredients typically found in most soft drinks include water, sweetener, acid and flavourings. Optional ingredients include fruit, carbon dioxide, preservatives and colour. Water is the main ingredient of all soft drinks and, as such, the quality of the water, in terms of its microbiological loading and other parameters which affect the final sensory qualities of the drink, are of paramount importance. All sparkling soft drinks require the addition of carbon dioxide. This may be sourced as a co-product from the petroleum, beer and whisky industries, or produced on site. The preservation of soft drinks can be achieved by a number of techniques including heating, chemical preservation and filtration. These methods, in combination with low pH, prevent microbiological spoilage.

The basic processes for the manufacture of soft drinks involve the mixing of ingredients in the syrup room, followed by the addition of water that has been subjected to various water treatments. The mixture may be heat processed or chemically preserved at this stage. The product is carbonated if required. Alternatively, after the syrup and water are combined, the product may be filled into packaging and in-pack heat processed. Syrups may require filtration or homogenization and may be pasteurized. Most packaging is cleaned prior to filling, either by rinsing with water, possibly containing rinsing aids, or by air blasting.

Table 1: pH-ranges of various soft drinks

Table 2: Illustration of a typical soft drink formula

Table 3: Storage conditions of soft drinks raw materials

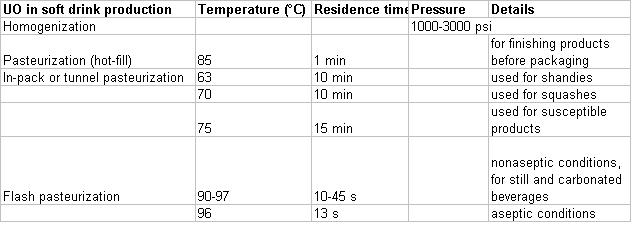

- 3. Temperature ranges and other parameters (table)

- 4. Benchmark data

No information is available.

2. NEW TECHNOLOGIES:

- a) Changes in the process

- No information is available.

- b) Changes in the energy distribution system

- No information is available.

- c) Changes in the heat supply system

- No information is available.

3. SOLAR SYSTEMS INTEGRATION:

Critical issues concerning the possible solar integration

Reference: Caballero, B., Finglas, P., Trugo, L.: Encyclopedia of food science and nutrition, Academic Pr. Inc., 2003, pages 5352-5358