Sterilization in food industry

Back to EFFICIENCY FINDER

1. OBJECTIVE

Heat treatment of products is one of the main techniques in the food industry for food conservation. Heat treatment stops bacterial and enzyme activity; thus preventing a loss of quality and keeping food non-perishable (BAT in the Food, Drink and Milk Industries, June 2005).

- Sterilisation: (BAT in the Food, Drink and Milk Industries, June 2005)

- Sterilization is a controlled heating process used to completely eliminate all living micro-organisms, including thermoresistant spores in milk or other food. It can be achieved by moist heat, dry heat, filtration, irradiation, or by chemical methods. Compared to pasteurisation, a heat treatment of over 100°C is applied for a period long enough to lead to a stable product shelf-life.

- UHT (Ultra-High Temperature) sterilization: (BAT in the Food, Drink and Milk Industries, June 2005)

- UHT (Ultra-High Temperature) sterilization has a heat treatment of over 100°C during very short times; it is especially applicable to low viscous liquid products. The basis of UHT, or ultra-high temperature, is the sterilization of food before packaging, then filling into pre-sterilized containers in a sterile atmosphere.

2. FIELD OF APPLICATION

Sterilisation is used to treat all types of food products. These include milk, juices, beer and many others. UHT sterilization is used for low viscosity liquid products (milk, juices, cream, wine, salad dressings), foods with discrete particles (baby foods, tomato products, fruits and vegetables juices, soups) and larger particles (stews) (BAT in the Food, Drink and Milk Industries, June 2005).

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

Generally in sterilization, the product is canned or bottled and then heat-treated in a sterilizer. Sterilizers may be batch or continuous. In heat treatment processes, various time/temperature combinations can be applied, depending on the product properties and shelf-life requirements

- Sterilization

(Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

- Sterilization with moist heat:

- In sterilisation with moist heat, temperatures generally range from 110 to 130°C with sterilization times being from 20 - 40min. For example, canned foods are sterilised in an autoclave at about 121°C for 20min. Higher temperatures and shorter times may have similar effects, e.g. 134°C for 3min. However, if conditions do not allow the germination of spores, lower temperatures and shorter times can also be applied. For example, with acid fruit juices, jam, or desserts, heating to 80 – 100°C for 10min is normally sufficient.

- Sterilization with dry heat:

- For killing bacterial endospores by dry heat, longer exposure times (e.g. up to 2 hours) and higher temperatures (e.g. 160 – 180°C) are required than with moist heat.

- Sterilization by chemical means:

- Chemical means may also be applied. Ethylene oxide is used to sterilize food, plastics, glassware, and other equipment. [87, Ullmann, 2001]

- UHT Treatment

(Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

UHT treatment means a very short heat treatment at temperature of approximately 140°C (135 - 150°C) for only a few seconds. This results in a sterilized product with minimal heat damage to the product properties. UHT treatment is only possible in flow-through equipment. The product is thus sterilized before it is transferred to pre-sterilized containers in a sterile atmosphere. This requires aseptic processing. There are two principal methods of UHT treatment:

- Direct heating:

- The product is heated by direct contact with steam of potable or culinary quality. The main advantage of direct heating is that the product is held at the elevated temperature for a shorter period of time. For a heat-sensitive product (for example milk), this means less damage. There are two methods of direct heating: (a)injection and (b)infusion.

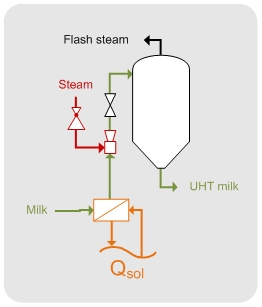

Figure 1: Injection and infusion for direct heating in UHT treatment LITERATURE: http://www.foodsci.uoguelph.ca/dairyedu/home.html

- (a) Injection:

- High pressure steam is injected into pre-heated liquid by a steam injector leading to a rapid rise in temperature. After ::holding, the product is flash-cooled in a vacuum to remove water equivalent to amount of condensed steam used. This method ::allows fast heating and cooling, and volatile removal, but is only suitable for some products. It is energy intensive and ::because the product comes in contact with hot equipment, there is potential for flavour damage.

- (b) Infusion: The liquid product stream is pumped through a distributing nozzle into a chamber of high pressure steam. This ::system is characterized by a large steam volume and a small product volume, distributed in a large surface area of product. ::Product temperature is accurately controlled via pressure. Additional holding time may be accomplished through the use of plate ::or tubular heat exchangers, followed by flash cooling in vacuum chamber. This method has several advantages: instantaneous ::heating and rapid cooling, no localized overheating or burn-on and suitable for low and higher viscosity products.

- Indirect heating:

- The heating medium and product are not in direct contact, but separated by equipment contact surfaces. Several types of heat exchangers are applicable:

- (a)plate,

- (b)tubular,

- (c)scraped surface and

- (d)double-cone.

- (a) Plate Heat Exchangers:

- Similar to that used in HTST but operating pressures are limited by gaskets. Liquid velocities are low which could lead to uneven heating and burn-on. This method is economical in floor space, easily inspected, and allows for potential regeneration.

- (b) Tubular Heat Exchangers:

- There are several types: shell and tube, shell and coil, double tube and triple tube. All of these tubular heat exchangers have fewer seals involved than with plates. This allows for higher pressures, thus higher flow rates and higher temperatures. The heating is more uniform but difficult to inspect.

- (c) Scraped Surface Heat Exchangers:

- The product flows through a jacketed tube, which contains the heating medium, and is scraped from the sides with a rotating knife. This method is suitable for viscous products and particulates (< 1cm) such as fruit sauces, and can be adjusted for different products by changing configuration of rotor. There is a problem with larger particulates; the long process time for particulates would mean long holding sections which are impractical. This may lead to damaged solids and overprocessing of sauce.

- (d) Double-cone Heat Exchangers:

- Suitable for large particulates because it involves separation of solids/liquids and combines indirect heating in double cone (batch) with direct heating of liquid portion (maybe also scraped surface if too viscous). The solid pieces are fed into a double-cone, rotated slowly on horizontal axis with steam injection and heated surfaces. There is no burn-on because they are the same temperature. The liquid is directly heated with steam separately, then added after pre-cooling. The double cone acts as a blender and coats solids. The product is then discharged to an aseptic filler by overpressure with sterile air. Used for soups, stews, carrots, and vegetables.

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

- Use of continuous sterilizers after filling of cans, bottles and jars: (BAT in the Food, Drink and Milk Industries, June 2005)

- Continuous sterilizers enable close control over processing conditions and so produce more uniform products. They produce gradual changes in pressure inside the cans, bottles and jars and, therefore, less strain on the seams compared with batch equipment. Continuous sterilizers, e.g. cooker-coolers, can vary slightly in design and size. Some models can accommodate up to 25000 cans, bottles or jars. They carry them on a conveyor through three sections of a tunnel that are maintained at different pressures for preheating, sterilizing and cooling. The food can be cooked during preheating and sterilizing.

- The water is re-used continuously and water is added, as required, to replace the minimal evaporation loss, thereby controlling the amount of water and energy consumed. The water is re-used for cleaning when it can no longer be used in sterilization. In this way, the consumption of water and energy is reduced.

- The main disadvantages of continuous sterilization include a high in process stock which would be lost if a breakdown occurred, and in some problems, with metal corrosion and contamination by thermophilic bacteria may occur, if adequate preventing measures are not taken.

- Sterilization by filtration: (Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

- Solutions containing thermolabile compounds can be sterilised by filtration through mediums such as nitrocellulose membranes, kieselguhr, porcelain, asbestos (see also Membrane processes).

- Sterilization by UV-radiation: (Operations in Food Processing - the Web Edition, R. L. EARLE, 1983)

- UV irradiation is used to keep rooms partially sterile. Bacteria and their spores are killed quickly, but fungal spores are only moderately sensitive to radiation. Ionising radiation (X ray, gamma radiation) is used to sterilise food and other compact materials.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

Back to EFFICIENCY FINDER