Sugar

Back to Information about sugar

I. GENERAL DESCRIPTION:

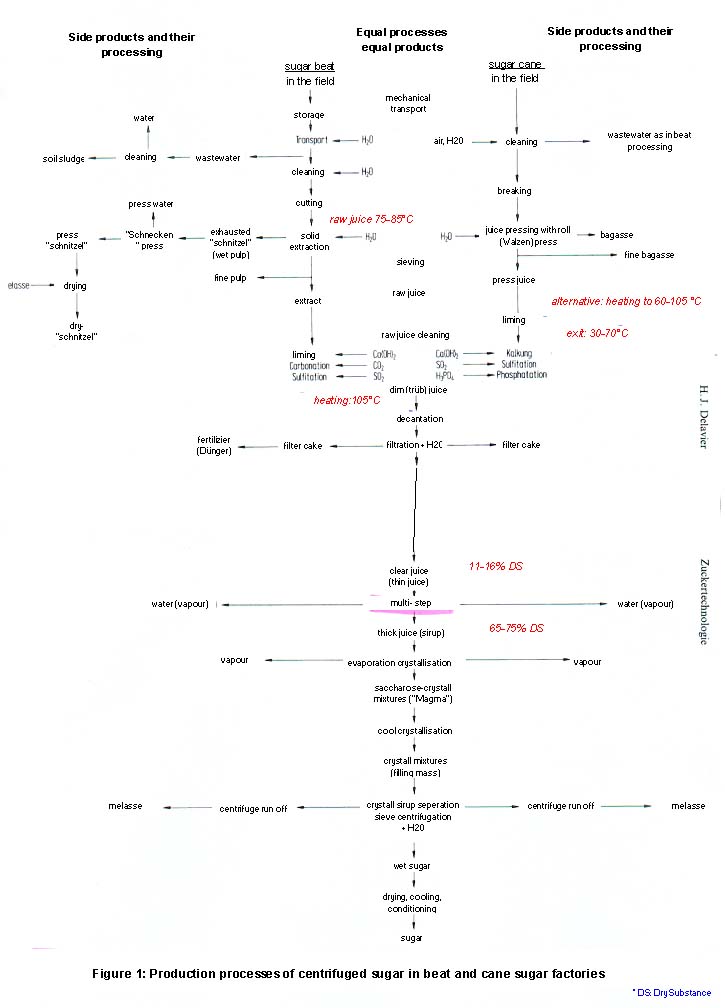

- 1. General Flowsheet of sugar production

LITERATURE: ?, H.J.Delavier

- 2. Description of techniques, methods and equipment

- (BAT in the Food, Drink and Milk Industries, June 2005)

Sugar (sucrose) is produced from two principal sources, sugar beet and sugar cane. Sugar beet tends to be grown in Europe and sugar crane in hotter climates, such as West Indies. Production of sugar by sugar beets is a single process technology.

Production of sugar by sugar cane consists of two processes:

- 1) Raw cane sugar production:

- Raw cane sugar is usually separated, purified and crystallized in the country of origin. The cane sugar, which is in a crudely refined state, undergoes final processing when transferred to the country of use.

- 2) Sugar refining:

- Raw sugar is typically a minimum of 96% sucrose. The impure crystals, with adhering molasses, are blended in a saturated sugar solution to soften the surface molasses film which can then be removed by centrifugation. The partly processed sugar is dissolved in reclaim solutions, i.e. light waters from the refining process. Carbonation, which is treatment with milk of lime and carbon dioxide, then follows. This produces a precipitate which contains impurities such as pectins and proteins and removes suspended impurities such as waxes, gums and starches. The sugar syrup is filtered and decolourized using ion exchange resins and activated carbon to produce a fine liquor, which may be solved as finished product or passed on for crystallization.

- The fine liquor is concentrated by evaporation to produce a syrup of around 60-70% solids, known as thick juice. The juice is filtered and transferred to vacuum pans. When the liquor is slightly supersaturated, the pan is seeded with fine icing sugar to initiate crystallization. The mixture is centrifugally separated to extract crystalline sugar, which is dried, conditioned for packaging or bulk loaded. Each pan boiling yields around 50% of the available sugar.

- The liquor separated during centrifugation, also called jet, is re-boiled for further extraction. Three billings yield white sugar. A fourth boiling yields off white industrial sugar. Jet four, together with liquor from blending, goes to a recovery house for three further boilings to produce brown sugars which go back to the start of the refining process and are treated as raw sugar. Various intermediary products from jets one to four and the corresponding syrups from recovery and boiling are sold as the starting materials for syrups such as molasses and treacle. Molasses are sometimes used in animal feed, alcoholic fermentation and a number of non-food products.

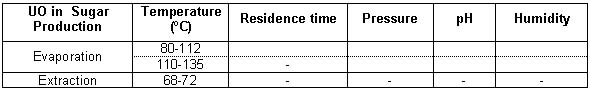

- 3. Temperature ranges and other parameters (table)

- (BAT in the Food, Drink and Milk Industries, June 2005 and ?)

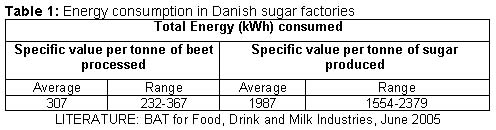

- 4. Benchmark data

- (BAT in the Food, Drink and Milk Industries, June 2005)

Significant energy is consumed for the evaporation and beet pulp drying. Electrical energy is needed for the pumps and for driving the centrifuges. According to CEFS, specific energy consumption was 31.49 kWh/100kg beet in 1998. The following table shows the energy consumption in Danish sugar factories:

In a greek study, a figure of 280 kWh/t is given for the electrical part of the energy consumption in sugar manufacturing.

II. NEW TECHNOLOGIES:

- a) Changes in the process

- Reducing sugar beet soil tare: (BAT in the Food, Drink and Milk Industries, June 2005)

- a) Description of the technology:

- Large quantities of soil, gravel and stones are transported to sugar factories as part of beet deliveries. Handling of this unwanted material consumes a lot of resources at the site, e.g. energy and water. A “clean beets” project, combining technical, economic and plant breeding measures, can reduce the amount of soil delivered to the installation.

- b) Description of suitable energy supply systems:

- The aim is to reduce the amount of soil tare before it’s delivered to the installation. The used technology involves mostly new harvesting and breeding technologies, which do not necessarily consume energy. Therefore, no specific energy supply system should be used.

- c) Possible energy savings reachable by those measures:

- No information available.

- d) Economic evaluations:

- No information available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.

III. SOLAR SYSTEMS INTEGRATION:

Evaporation in the sugar production requires a minimum temperature of 110°C. To achieve these temperatures, advanced solar collector types can be used (parabolic trough collectors) and the investment cost for the solar system may increase. Due to the fact that large amounts of hot water or steam may be required, auxiliary boilers can be used additionally to solar collectors (Joanneum Research).

Back to Information about sugar