Unsaturated polyester

Back to Information about unsaturated polyester

1 General description

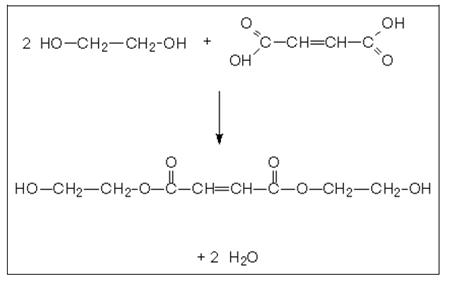

Unsaturated polyester resins are classified as thermosets. The producer supplies a reactive, liquid intermediate to the customer. This is different from the market for thermoplastics where a ready made polymer is delivered. The liquid intermediate is transferred into the final product at the customer site by curing it with hardeners or catalysts. Unsaturated polyester (UP) is the generic name for a variety of thermoset products, mainly prepared by polycondensation of an anhydride or a diacid (the monomer) with a diol (the reactant). The following Figure shows, in principle, the reaction of a glycol with a dicarboxylic acid. These condensation products are dissolved in a reactive monomer which is usually styrene. When this mixture is cured by the customer, a three-dimensional network is formed.

Figure 1: Basic condensation reaction scheme for producing unsaturated polyester resins

The properties of the cured UP resins can be varied within wide limits to meet specific requirements, by the choice of specific dicarboxylic (both unsaturated and saturated) acids and diols and by dissolving them in different reactive monomers. Using the appropriate combination of starting materials, it is possible to influence many properties of the resin, such as:

- heat resistance

- hydrolysis resistance

- impact strength

- flexibility

- electrical properties

- self-extinguishing properties.

Within the unsaturated polyester consumer market, a variety of formulations are used. The background to this is the large variety in end-use markets and the use of many different conversion technologies at the converter. Overall, hundreds of different formulations are brought to the market. Apart from differing in formulation (raw material composition), processes may differ to target desired specifications and product performance.

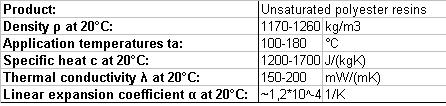

Table 1: Properties of UP, Literature: Hirschberg, H. G.: Handbuch Verfahrenstechnik und Anlagenbau

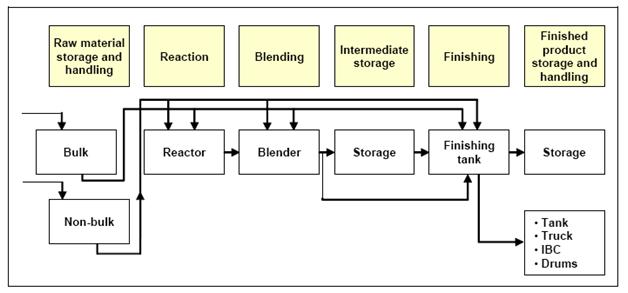

2 Flow diagram of UP production

Figure 2: Flow diagram of the UP production process

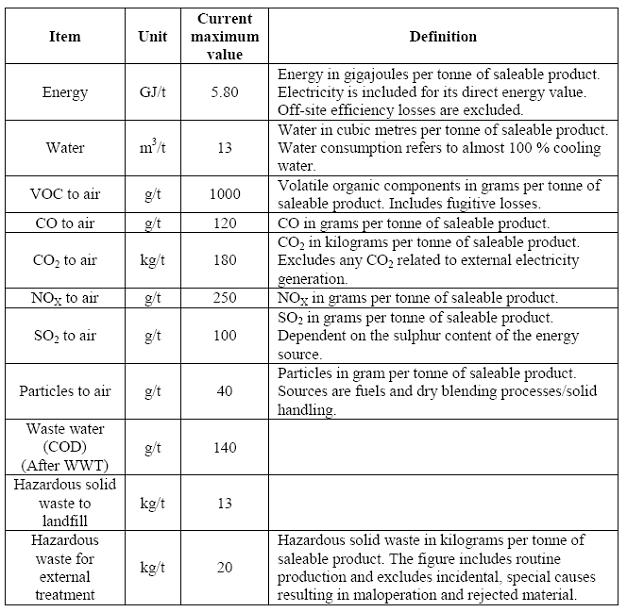

3 Current emission and consumption levels

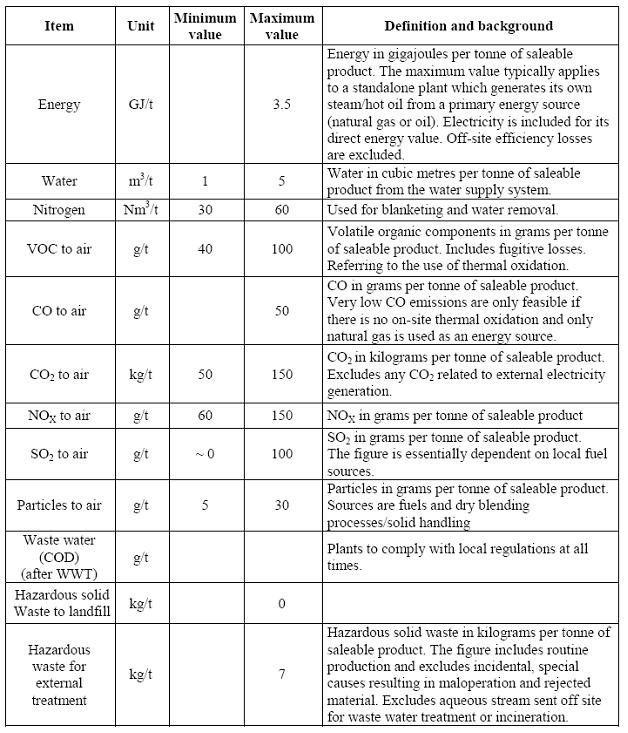

Table 1: Current maximum emission and consumption levels

Table 2: Good practice industry values for emission and consumption levels

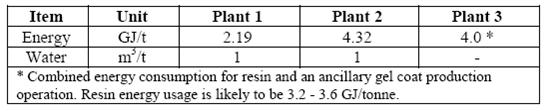

4 Consumption data for example UP plants

5 Emission and consumption levels associated with BAT for the production of polystyrene]]

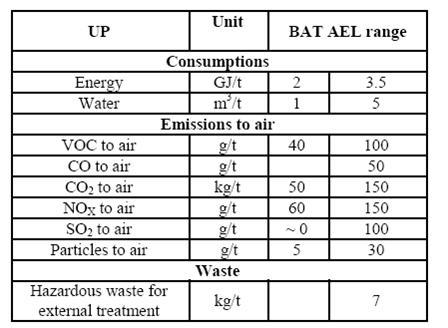

Table 4: BAT associated emission and consumption levels for the production of UP

Literature: BAT for Polymers, October 2006