Difference between revisions of "Washing of clothes"

From Efficiency Finder

(→Efficiency measures) |

|||

| Line 132: | Line 132: | ||

| − | '''Heat recovery''' | + | '''Heat recovery:''' |

| + | |||

The hot bath is passed through the heat exchanger and is cooled down. Fresh water is heated in the heat exchanger. | The hot bath is passed through the heat exchanger and is cooled down. Fresh water is heated in the heat exchanger. | ||

| Line 155: | Line 156: | ||

[[File:rotating_htex.png |400 px]] | [[File:rotating_htex.png |400 px]] | ||

| − | |||

| − | |||

== Source == | == Source == | ||

Leonardo da Vinci project [http://www.laundry-sustainability.eu Laundry Sustainability] | Leonardo da Vinci project [http://www.laundry-sustainability.eu Laundry Sustainability] | ||

Revision as of 15:40, 18 April 2017

Washer extractors

Washer extractors are applied for

- heavily soiled laundry

- textiles with bleeding colours

- small batches

- high quality workware

- infectous laundry

- cleanroom laundry

- medical devices

- sensitive laundry: wool blankets, curtains

- special laundry items (e.g. mattresses)

- wet clean

Design of the washing program:

- Pre wash

- Main wash

- Rinse with intermediate spin

- Neutralisation, Addition of Aids (starch, textile softener, acid)

- Final spin

Pre washing:

- Rapid wetting of laundry

- Swelling of soil

- Removal of heavy soil from the laundry

- Dissolving and swelling of spots

- Temperature: depends on amount and kind of soil -> blood 20 – 25 °C (> 30°C denaturation/fixing of proteins), fat/oil 50 – 60 °C (> 50°C good soil removal)

- Detergents: 50 – 70 % of total amount (reuse of rinse water increases detergent concentration, residues of peroxide cause denaturation/fixing of blood)

- Drain -> in sewage

Main wash:

- Removal of remaining soil

- Removal of oxidative spots

- Disinfection (thermal) at temperature > 85 °C

- Disinfection (chemical) at 40 °C (depends on disinfectant)

- Increase of textile whiteness

- Duration: approx. 10 – 15 min at temperature level

- Temperature: adapted to washing process and amount and kind of soil (e.g. thermal disinfection = 10 min at 90 °C or 15 min at 85 °C)

- Drain -> in sewage

Rinse:

- Removal of soil residues

- Removal of detergent residues (surfactants, alkali and bleaching agents)

- Duration: (total) approx. 8 – 12 min

- Temperature approx. 60 – 25 °C (without heating), depends on main wash temperature

- Drain in storage tanks

- Inactivation of bleach agents is needed if extracted water is reused

Neutralisation:

- In last rinse

- Reduction of textile pH-value for the purpose of preventing yellowing effect during drying or ironing process

- Duration approx. 2 – 4 min

- Temperature approx. 20 – 25 °C

- Formic or acetic acid in last rinse (recommended pH-values for flatwork 6,0-6,5, for fully dried laundry 6,0-6,5, for garments for tunnel finisher, flat press 5,5-6,5)

Spin:

- Mechanical dewatering by centrifugal force (g - factor up to 600, 5 - 10 min)

- Water content of laundry depends on´type of fabrics, drum, number of revolution (rpm), duration, temperature of laundry

- Intermediate spin between rinsing baths, minimisation of carry over effects of detergent residues in next rinse bath

- Problematic: wrinkling of PES/CO textiles at temperatures > 40 °C,high rpm and/or spin duration

Tunnel washers

Characteristics:

- Continuous washing process

- Counterflow principle: Constantly dilution of liquor

- Corrective: standing bath, bath exchange

- Liquor level nearly not alterable

- Low mechanics (oscillating)

- Diversification of mechanics and cycle time effects all compartments.

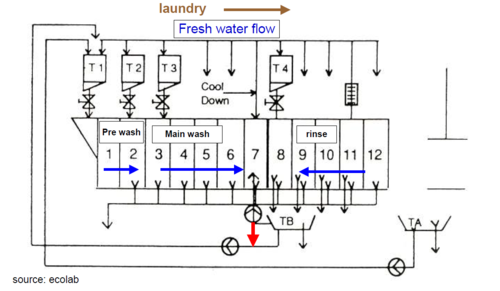

Schematics of a tunnel washer:

Number of compartments in a tunnel washer:

- soaking (optional): 1-2

- pre wash zone: 2-4

- main wash zone: 3 -6

- rinsing zone: 2-6

- finishing: 1-2

- dewatering

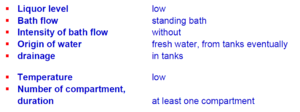

Parameters:

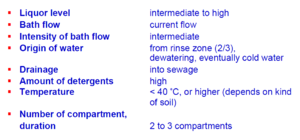

Pre washing

Main washing

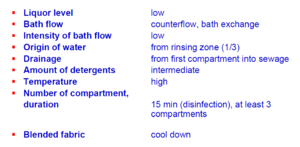

Rinsing

Finish

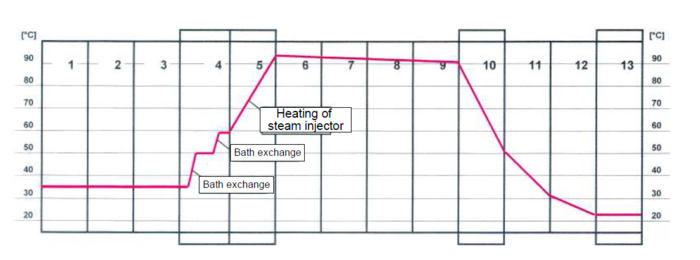

Distribution of temperature in a tunnel washer

Efficiency measures

Usage of storage tanks for washer extractors:

- Use of water from last in first rinse

- Use of water from rinsing in pre- and main wash

- Last rinse with fresh water quality only

- Savings: Water up to 40 %, Steam up to 45 %, Detergents up to 30 %

- Environmentally friendly

- Economical

- Quick return on investments

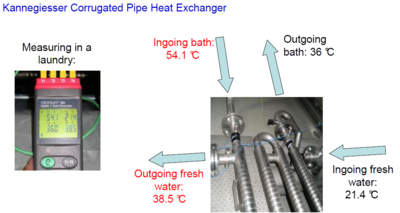

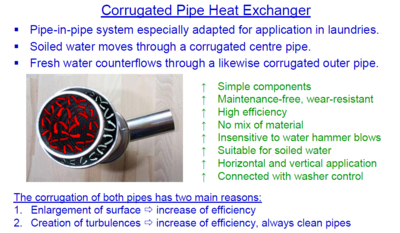

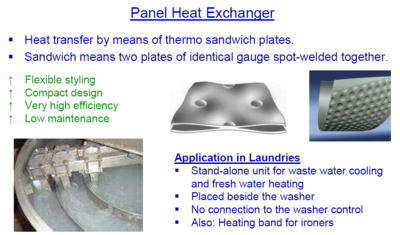

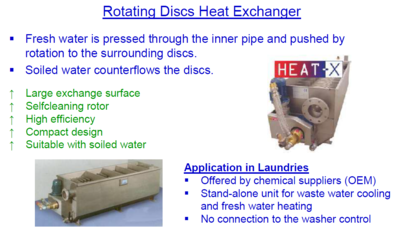

Heat recovery:

The hot bath is passed through the heat exchanger and is cooled down. Fresh water is heated in the heat exchanger.

Recovery potential:

40 - 45% (pre-wash temperature < 40°C)

> 45% (higher pre-wash temperatures possible)

Examples:

Source

Leonardo da Vinci project Laundry Sustainability