Wheat starch

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about starch, potatoes & grain milled production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of wheat starch production

- (BAT for Food, Drink and Milk Industries, June 2005)

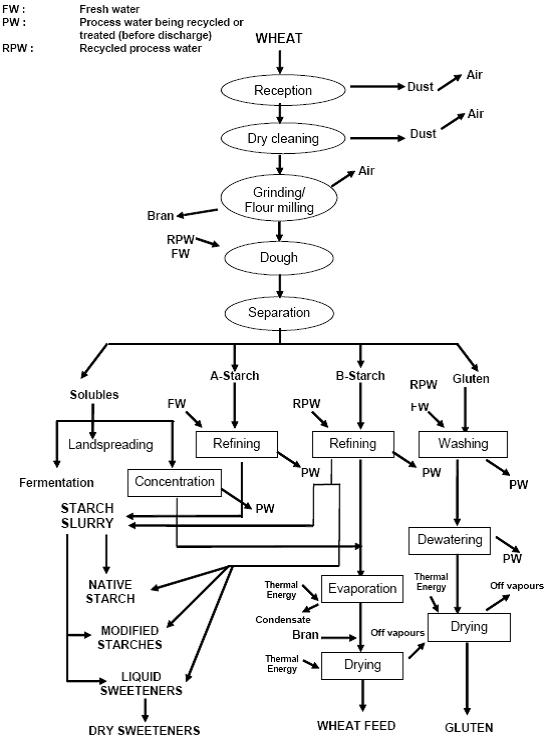

An example of a wheat starch extraction process is presented below:

Figure 1: Production of wheat starch. Literature: BAT in Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

The commercial separation of pure starch from wheat is achieved by a two-phase process. In the first phase, the wheat kernel is ground or converted into wheat flour by a dry milling process. The second phase then separates the ground wheat or the wheat flour into its separate components, i.e. starch, gluten, solubles and eventually fibre, by a wet separation process. The process is operated as an enclosed system in which process water is recycled in a closed circuit. Fresh water is used at some stages of the process. The process of washing raw wheat starch to produced refined starch is the same as for the maize starch.

- 3. Temperature ranges and other parameters (table)

- 4. Benchmark data

- (BAT for Food, Drink and Milk Industries, June 2005)

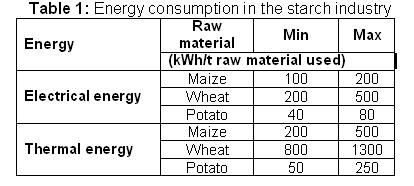

The energy consumption depends on the starch and starch derived products produced on the site, i.e. on the techniques and processes involved in the starch production and co-products management. However, the main use of energy in starch production is thermal energy for the evaporation and drying processes. The energy used to produce starch slurry is low in comparison to the final production of dry products. More energy is consumed at sites where evaporation and/or drying processes are used for co-products such as fibre, soluNes and proteins than at sites where solubles are landspread and fibre is sold as wet cattle feed. The general consumption of energy in the starch sector is given in the following table:

2. NEW TECHNOLOGIES:

- a) Changes in the process

- b) Changes in the energy distribution system

- c) Changes in the heat supply system

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about starch, potatoes & grain milled production