Difference between revisions of "Boiler feed-water preheating in bread , biscuits and cakes"

| Line 2: | Line 2: | ||

| − | + | '''BOILER FEED WATER PREHEATING IN BAKERIES :''' | |

| + | |||

| + | |||

| + | == Description: == | ||

| − | |||

The efficiency of a boiler’s steam production may be improved by increasing the efficiency of heat transfer by the heat carrying medium. The feed-water absorbs the heat produced from combustion and steam is produced. The higher the temperature of the feed-water when it enters the boiler, the larger quantities of high quality steam will be produced, because little energy is lost to increase the feed-water temperature from ambient to evaporation conditions (BAT in the Food, Drink and Milk Industries, June 2005). | The efficiency of a boiler’s steam production may be improved by increasing the efficiency of heat transfer by the heat carrying medium. The feed-water absorbs the heat produced from combustion and steam is produced. The higher the temperature of the feed-water when it enters the boiler, the larger quantities of high quality steam will be produced, because little energy is lost to increase the feed-water temperature from ambient to evaporation conditions (BAT in the Food, Drink and Milk Industries, June 2005). | ||

| Line 12: | Line 14: | ||

| − | + | == Applications: == | |

| + | |||

It is used in all [[Information about bread, biscuits & cakes production|Information about bread, biscuits & cakes production]] | It is used in all [[Information about bread, biscuits & cakes production|Information about bread, biscuits & cakes production]] | ||

| − | + | == Flowsheet: == | |

A typical Diagram of the Boiler Feed-water Preheating process | A typical Diagram of the Boiler Feed-water Preheating process | ||

| Line 22: | Line 25: | ||

[[Image:Bakery_FWPre.gif]] | [[Image:Bakery_FWPre.gif]] | ||

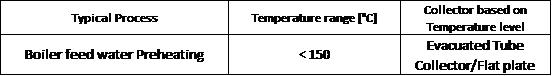

| − | + | == Typical parameters of the process == | |

| − | + | ||

[[Image:Bakery_FWTemp.png]] | [[Image:Bakery_FWTemp.png]] | ||

| − | |||

Revision as of 14:37, 26 August 2014

Back to EFFICIENCY FINDER OF FOOD INDUSTRY

BOILER FEED WATER PREHEATING IN BAKERIES :

Description:

The efficiency of a boiler’s steam production may be improved by increasing the efficiency of heat transfer by the heat carrying medium. The feed-water absorbs the heat produced from combustion and steam is produced. The higher the temperature of the feed-water when it enters the boiler, the larger quantities of high quality steam will be produced, because little energy is lost to increase the feed-water temperature from ambient to evaporation conditions (BAT in the Food, Drink and Milk Industries, June 2005).

Usually the boiler feed water preheating is performed by Indirect Heating using Heat Exchanger Tanks and Solar collectors depending on the requirement. Evacuated Tube Collectors (ETC) to heat the feedwater from 25 deg C to 70 deg C (avg.) are better than Flat plate collectors because of its lower cost, No scalign issues and ability to use diffusion radiation too for heating the water.

Heat recovery from the flue gas of the ovens can be used to preheat boiler feedwater in an economiser. the limiting factor is that the economiser wall temperature must not drop below the dew point of acids contained in the flue gas.In fact, the economiser wall temperature is much more dependent on feed water temperature than on flue gas temperature because of the high heat transfer coefficient of water. As a result it makes sense to preheat feed water to close to the acid dew point before it enters the economiser.Typically 1% of fuel use is saved for every 25 degrees celsius reduction in exhaust gas tewmperature.(Ganapathy,1994)

Applications:

It is used in all Information about bread, biscuits & cakes production

Flowsheet:

A typical Diagram of the Boiler Feed-water Preheating process

Typical parameters of the process