Difference between revisions of "Cooling, chilling and cold stabilization in beer production"

From Efficiency Finder

| Line 17: | Line 17: | ||

{| border="1" | {| border="1" | ||

| − | | align="left" style="background:yellow"|''' | + | | align="left" style="background:yellow"|'''Beer products''' |

| align="center" style="background:orange"|'''Temperature [°C]''' | | align="center" style="background:orange"|'''Temperature [°C]''' | ||

| align="center" style="background:orange"|'''Pressure (bar)''' | | align="center" style="background:orange"|'''Pressure (bar)''' | ||

Revision as of 14:05, 9 November 2010

Back to EFFICIENCY FINDER FOR FOOD INDUSTRY

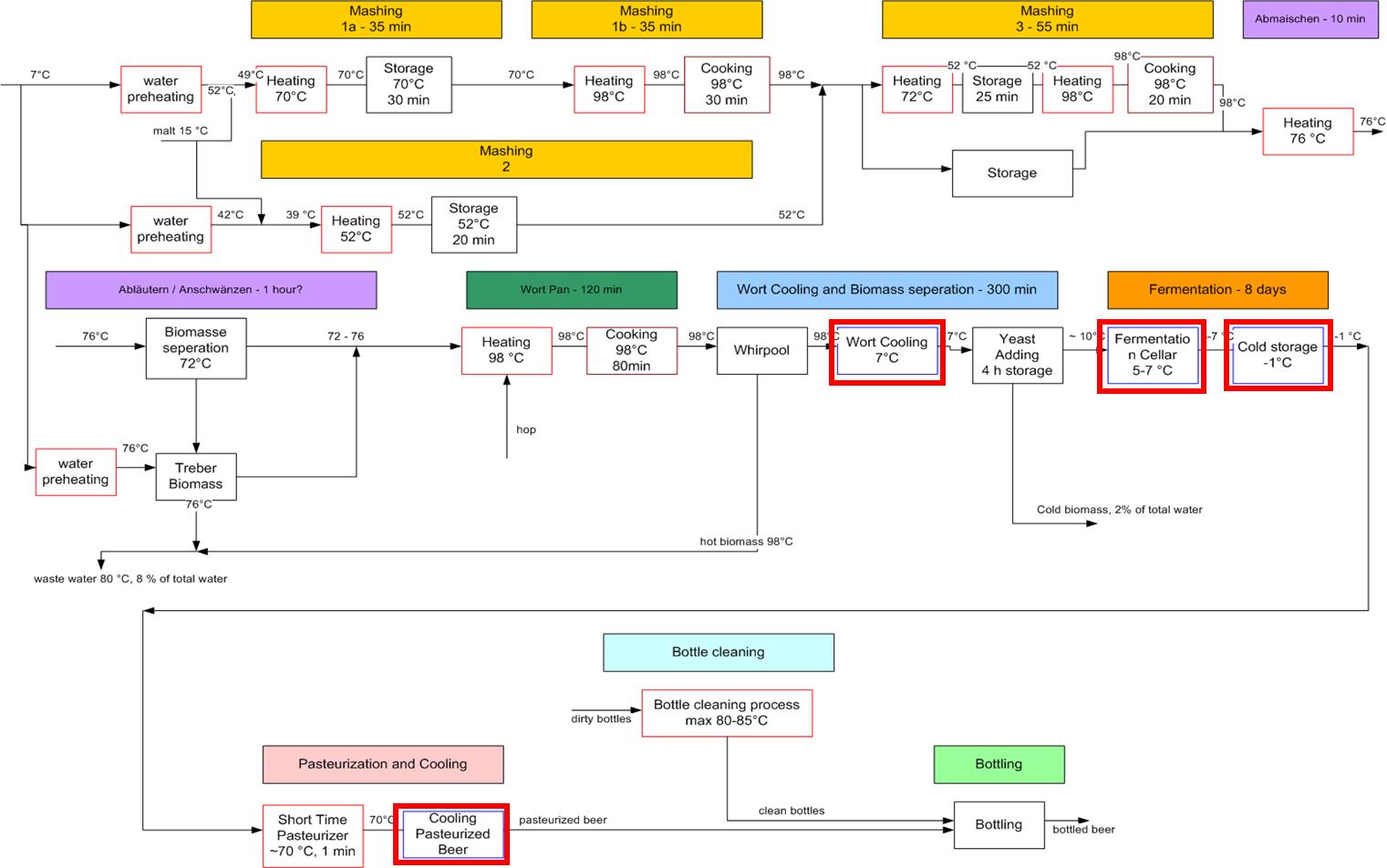

- Cooling in breweries

Literature: Case study: Murauer Brewery (Joints)

- Typical parameters of the process

| Beer products | Temperature [°C] | Pressure (bar) | Heat absorbing medium | Residence Time | Details | Literature |

| Beer | 98 to 7 | water | 5-15min | wort cooling | Case study: Murauer brewery (JOINTS) | |

| 5-10 | referigating medium | 5-10 days | fermentation cellar | |||

| 5 to -1 | 8-10 days | cold storage | ||||

| 70 to ambient | water | cold pasteurized beer |