Cooling during chemical reactions in chemical industry

Back to EFFICIENCY FINDER FOR CHEMICAL INDUSTRY

1. OBJECTIVE

The removal of heat from exothermic processes is very important for process control and safety reasons, and cooling may also be required to create the right conditions for certain process steps.

2. FIELD OF APPLICATION

Cooling during chemical reactions is a process applied to exothermic and highly exothermic chemical reactions.

3. DESCRIPTION OF TECHNIQUES, METHODS AND EQUIPMENT

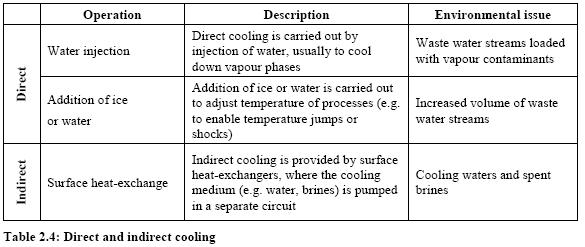

Cooling can be carried out directly or indirectly. Direct cooling is also used as a reaction stopper in emergency situations. (BAT on Organic Fine Chemicals, Aug. 2006)

Nearly all LVOC installations have an extensive cooling system; most commonly using water as the cooling medium, but with increasing use of air-cooling. For cooling below approximately 20°C, other cooling media are normally required (e.g. ammonia, hydrocarbons, carbon dioxide).

A wide variety of cooling technologies is available. The application of cooling systems is highly dependent on site-specific conditions and each case needs to be evaluated. The main considerations are:

- Potential losses of process material which depend heavily on the effectiveness of the cooling systems used for condensation

- Resource consumption (water, air, energy, chemical substances)

- Emissions to water (chemicals and heat) and air noise plumes and waste generation

- Risk aspects

- Pollution arising from specific events (starts/stops) or incidents

- Effects of process and equipment design, and of material and maintenance

- De-commissioning of installations

4. COMPETITIVE TECHNOLOGIES AND ENERGY SAVING POTENTIALS

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

As a general rule, cooling systems are only adopted when arisings of waste heat have been minimized and all opportunities for heat re-use have been exhausted. By applying such heat integration, significant energy can be saved and the associated emissions reduced. (BAT in the Large Volume Organic Chemical Industry, February 2003)

- c) Changes in the heat supply system

No information is available.