Curdled milk production

Back to Information about milk products

1. GENERAL DESCRIPTION:

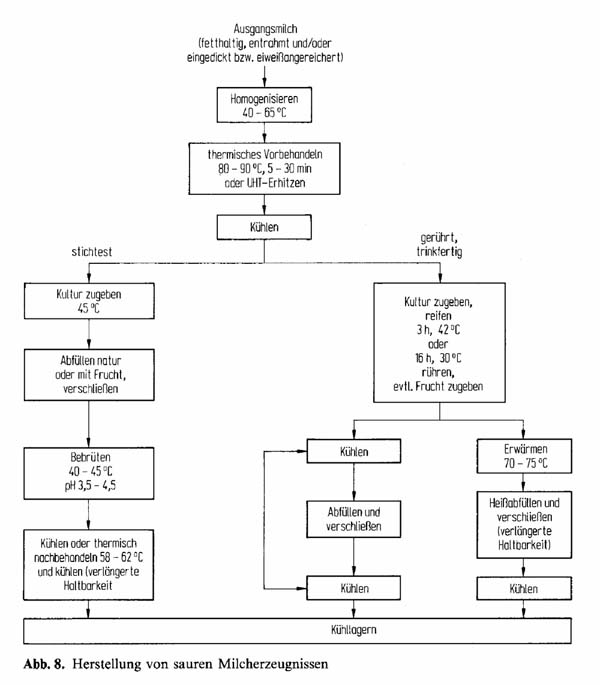

- 1. General Flowsheet

Figure 1: Flowsheet of curdled milk production

- 2. Description of techniques, methods and equipment

The feed milk is homogenized and treated thermally, either using pasteurization or UHT process. The thermal treated product is cooled and two possible paths can be followed then. The first path involves culture adding, bottling and sealing, incubation and, finally, cooling or thermal storage and then cooling. Alternatively, the second path involves culture adding, maturing, use of fruit additives, stirring, and then cooling or thermal storage, bottling and sealing and finally cooling.

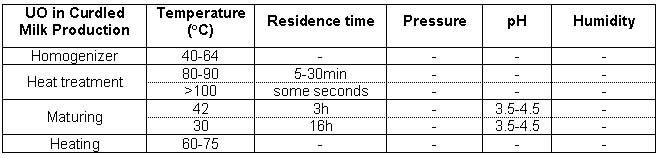

- 3. Temperature ranges and other parameters (table)

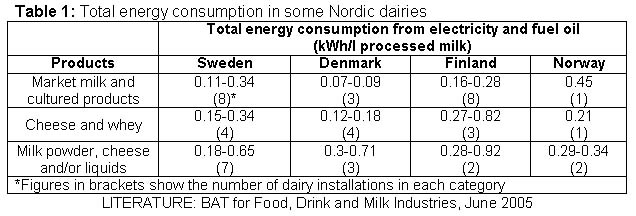

- 4. Benchmark data

2. NEW TECHNOLOGIES:

See information for dairies.

3. SOLAR SYSTEMS INTEGRATION:

Heat treatment can be achieved at temperatures either 90°C or >100°C. In the first case, the temperature level of the process (90°C) is easily reachable by using solar systems. In the second case, the thermal treatment process (>100°C) may require advanced solar collector types (parabolic trough collectors) and the investment cost for the solar system may increase. Due to the fact that large amounts of hot water or steam may be required, auxiliary boilers can be used additionally to solar collectors (Joanneum Research).

Back to Information about milk products