Description of the rinsing process

Back to Rinsing in metal industry

Drag-out and rinse

Drag-out is the liquid from the previous process which adheres to the workpiece or substrate surfaces. Rinsing is necessary:

- between most process steps to prevent cross-contamination of process solutions

- over-reaction or by staining by the drying of dissolved chemicals.

A reduction of drag-out is a primary measure for minimising losses of chemicals, operating costs and environmental problems in rinse-waters. In some processes, such as etching in anodising, a certain amount of drag-out is used to maintain the solution by preventing the build-up of by-products, such as in aluminium etching.

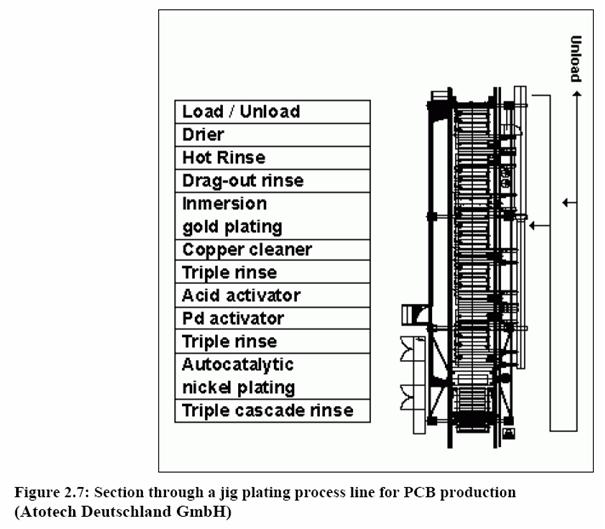

Rinsing is therefore a common activity carried out after nearly all process steps in surface treatment. The following figure shows a section through a typical jig plating line with six rinsing stations.

Rinse-water may vary in quality depending on the process requirements. Many rinsing techniques have been developed to reduce water consumption to a minimum. There is usually a balance to be sought between achieving the requisite cleanliness of the surface, the quality and quantity of the water used, and the way rinsing is carried out.

Rinsing is one of the two largest water usages in installations (the other large use is cooling).

Source: BAT Surface Treatment of Metals and Plastic, Aug. 2006.

Back to Rinsing in metal industry