Information about Breakfast cereals

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

- 1.1 General Flowsheet of cereal production

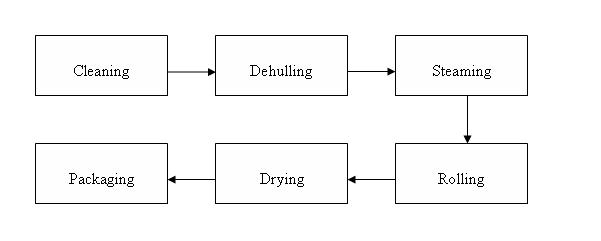

Figure 1: Flow sheet diagram for the production of hot cereals

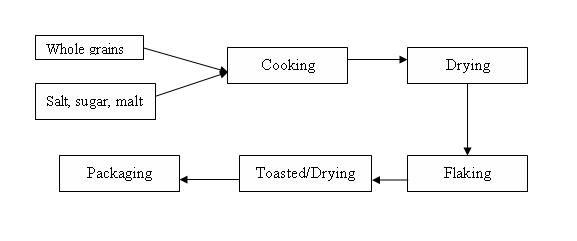

Figure 2: Flow sheet diagram for the production of flaked cereals

- 1.2 Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

Breakfast Cereals (BC) have been defined as processed grains for human consumption. The major grains used in manufacture are corn, rice, wheat, oats and barley. Furthermore BC can be divided into two groups: Ready-to-eat (RTE) and hot cereals (HC) or ready- to-cook. RTE Cereals are frequently made from mixtures of one or several grain components with other ingredients. Extensive processing is required and vitamins and other minerals are added. They packaged in special ways to protect their flavour, texture and nutrition during storage. The group of RTE cereals include products such as flaked cereals, puffed cereals, shredded cereals, granola cereals and extruded expanded cereals. HC are made from a single grain component and only relatively simple processing and packaging technologies are required. Comparing the prices at the consumers’ level reflects a higher prize for a single serving of RTE cereals for the costumers. HC have to be cooked or heated in water before consumption. Important HC are wheat farina, cracked wheat and bulgur and corn grits.

- 1.3 Temperature ranges and other parameters

- 1.4 Benchmark data

2. CHANGES IN PROCESSES:

- 2.1Changes in Energy Supply for unique Technology

- a) Existing Heat/Cool Technology

- b) Changes in Distribution of the Heat/Cool System

- c) Optimisation of the Heat/Cool System

- 2.1.1 Description of the Technology

- 2.1.2 Possible Energy Savings Reachable by those measures

- 2.1.3 Economic Evaluations

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production