Information about biscuits, cookies and crackers

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

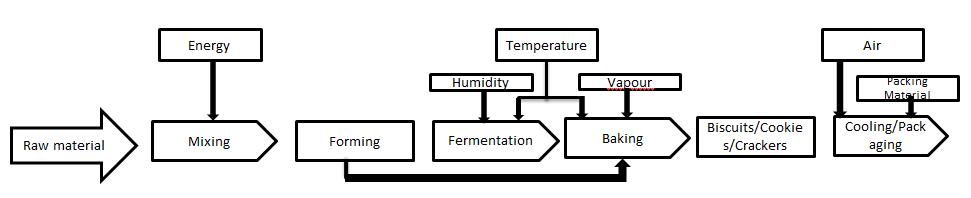

- 1. General Flowsheet of biscuits, cookies and crackers production

Figure 1: Flow sheet diagram of manufacturing, Literature: Caballero, B., Finglas, P., Trugo, L.: Encyclopedia of food science and nutrition

- 2. Description of techniques, methods and equipment

The word ‘biscuit’ means different things to different people. In America, the word describes a chemically leavened (baking powder) bread-type product, the nearest equivalent in New Zealand being a scone. Products known as biscuits here, and in the United Kingdom, are called ‘cookies and crackers’ in the USA.

In France, Switzerland and Italy, a great quantity of simple, plain biscuits are made by large manufacturers. Many varieties are also made by bakers. Biscuits which require more work and a degree of decoration are referred to as ‘Petit Fours Secs’. Others include ‘Tea Fancies’, which if made small would be referred to in France as ‘Les Petits Gateaux Sec’ or in the UK as ‘Fancy Biscuits’.

Biscuits differ from other baked cereal products such as bread and cakes by having a low moisture content. Bread typically has 35 – 45% moisture, cake, 15 – 30%, and biscuits, 1 – 5% moisture. This low moisture content ensures that biscuits are generally free from microbiological spoilage and have a long shelf life if they are protected from absorbing moisture from damp surroundings or atmosphere. Biscuits have relatively high energy density compared with other baked goods.

The main ingredients used for biscuit manufacture are wheat flour, fat and sugar. Water, which is present in flour at about 14% by weight of sample (that is 14% of the flour is water), is also required at the dough mixing stage, along with other ingredients such as sugar syrups, but these are largely removed during the baking process. Water does, however, play an important role in biscuit making.

- Classification can also be based on the method of processing

- Sheeting and cutting (used for making crackers)

- Rotary molding (used for short doughs which require a not too sticky consistence)

- Wire cutting (also used for short doughs)

- Depositing (used for soft doughs)

- Crackers made from hard doughs

Crackers are characterized by their low level of fat and sugar. They are often used as a base of a savory topping such as cheese or tomato. They can further be subdivided into those that are fermented, including soda crackers, saltines and cream crackers and those that are chemically leavened like the snack crackers.

- Soda crackers

They have their name from the sodium bicarbonate which is added to the dough. Their shortening content is about 8%. Normally they are quite dry and bland.

- Saltines

They are a smaller and more dainty type of soda crackers with an increased amount of shortening.

- Cream crackers

Despite their name they content no cream. They have just a slightly higher fat content than soda crackers (12-18%). They have a final moisture content of 3-4% which is relatively high for a cracker. Because of the increased fat content the cracker is quite soft and will not crumble.

- Snack or savory crackers

They are sprayed with hot oil as they leave the ovens. Also a topping is applied before baking to add flavour. Typical toppings include herb, cheese, salt and/or chicken. The crackes can also be decorated with small seeds such as poppy or sesame. Usually they contain also some sugar which also adds flavour and texture. Normally they are chemically leavened, but they can also be made from fermented doughs.

- Sweet and semisweet biscuits made from hard doughs

The dough of this kind of crackers has higher contents of sugar and fat. Unlike cracker doughs it is chemically leavened.

- Biscuits or cookies made from short doughs

The vast majority of worldwide consumed biscuits and cookies are made from short doughs. The range of size, shapes, flavours and ingredients is huge, but some consistent requirements exist. The used flour is usually weak and the proportions of fat and sugar can range up to 100 and 200% of flour weight. The two main processes for forming short dough biscuits are rotary molding and wire cutting.

- Biscuits and cookies made from soft doughs

Soft doughs are typically rich in fat (65-76% of flour weight) and sugar (35-40%). Weak flour is used and mixing is in a two-stage process. Often rich and expensive ingredients are used in soft doughs such as almonds, coconut flour or cocoa.

- The basic steps in manufacturing are

- 1. Dough mixing

The raw materials are received in bulk and are automatically metered into dough mixers. Small ingredients (eg. salt) are added by hand. The processes are accomplished with three principal types of mixers: vertical spindle mixers, horizontal drum mixers and continuous mixers.

- 2. Formation

The forming step is specific to each product type. There are three processes used to form cookie and cracker dough:

- Cutting or stamping

- Rotary molding

- Extruding

- 3. Backing

Baking usually takes places in tunnel ovens. The ovens themselves may be direct or indirect fired, gas or electric and vary in length and band width. The backing time and temperature depend on the nature of the dough.

- 4. Cooling

After baking biscuits are cooled by conveying them around the plant for a set of time period.Also the Biscuits can be made by 4 methods the melting method eg:Gingerbread, the rubbing in method , where the biscuits are usually rolled out and cut in shapes, the creaming method eg: Choco chip cookies, whisking method eg:Fortune cookies.

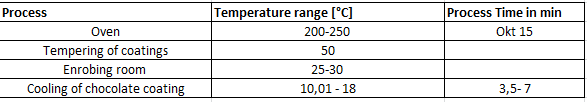

- 3. Temperature ranges and other parameters

Table 1: manufacturing-processes in 190-chocolate-and-chocolate-flavoured-coatings, Biscuit Doctor.

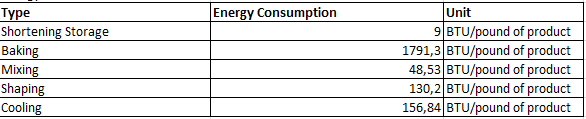

- 4. Benchmark data

Table 1: Energy Consumption, Literature: Energy efficiency improvement and cost saving opportunitieas for the bakign industry.Eric Masanet,Peter Therkelsen and Ernst Worrell

2. CHANGES IN PROCESSES:

- 2.1Changes in Energy Supply for unique Technology

- a) Existing Heat/Cool Technology

- b) Changes in Distribution of the Heat/Cool System

- c) Optimisation of the Heat/Cool System

- 2.1.1 Description of the Technology

- 2.1.2 Possible Energy Savings Reachable by those measures

- 2.1.3 Economic Evaluations

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production