Difference between revisions of "Information about cake"

| Line 7: | Line 7: | ||

| − | ;1. General Flowsheet of cake production: | + | ;1.1 General Flowsheet of cake production: |

[[Image: cake production.JPG]] | [[Image: cake production.JPG]] | ||

| Line 14: | Line 14: | ||

| − | ; | + | ;1.2 Description of techniques, methods and equipment: |

(BAT for Food, Drink and Milk Industries, June 2005) | (BAT for Food, Drink and Milk Industries, June 2005) | ||

| Line 34: | Line 34: | ||

| − | ; | + | ;1.3 Temperature ranges and other parameters |

<br/>[[File:Bakery_Cake_Temperature.png]] | <br/>[[File:Bakery_Cake_Temperature.png]] | ||

| Line 40: | Line 40: | ||

| − | ; | + | ;1.4 Benchmark data: |

| Line 47: | Line 47: | ||

Table 2: Energy Consumption in BTU per pound of product, Literature: Energy efficiency improvement and cost saving opportunitieas for the bakign industry.Eric Masanet,Peter Therkelsen and Ernst Worrell. | Table 2: Energy Consumption in BTU per pound of product, Literature: Energy efficiency improvement and cost saving opportunitieas for the bakign industry.Eric Masanet,Peter Therkelsen and Ernst Worrell. | ||

| − | + | == 2. CHANGES IN PROCESSES: == | |

| − | + | ||

;2.1Changes in Energy Supply for unique Technology | ;2.1Changes in Energy Supply for unique Technology | ||

| − | |||

| + | ;2.1.1 Existing Heat/Cool Technology | ||

| − | ; | + | ;2.1.2Changes in Distribution of the Heat/Cool System |

| − | ; | + | ;2.1.3 Optimisation of the Heat/Cool System |

| − | ;2.1.1 Description of the Technology | + | ;2.1.3.1 Description of the Technology |

| − | ;2.1.2 Possible Energy Savings Reachable by those measures | + | ;2.1.3.2 Possible Energy Savings Reachable by those measures |

| − | ;2.1.3 Economic Evaluations | + | ;2.1.3.3 Economic Evaluations |

| − | + | ||

Revision as of 10:57, 13 August 2014

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production

1. GENERAL DESCRIPTION:

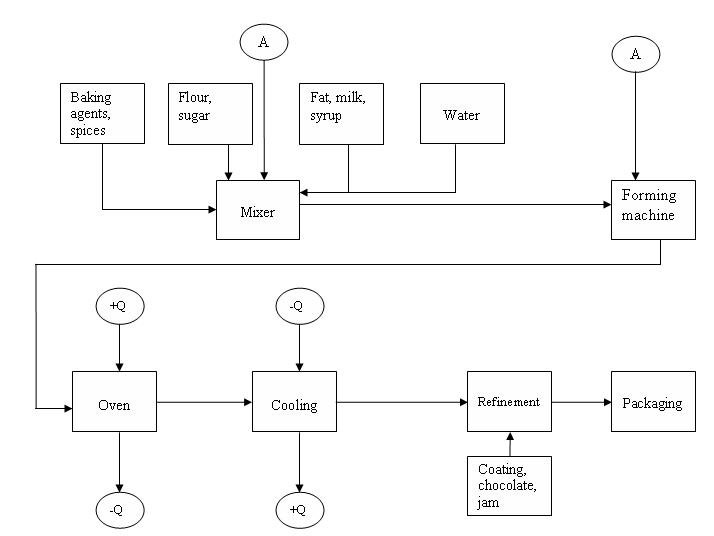

- 1.1 General Flowsheet of cake production

Figure 1: Production of cakes. Literature: Heiss, R. [Hrsg.]: Lebensmitteltechnologie

- 1.2 Description of techniques, methods and equipment

(BAT for Food, Drink and Milk Industries, June 2005)

Cake is a form of bread or bread-like food. In its modern forms, it is typically a sweet baked dessert. In its oldest forms, cakes were normally fried breads or cheesecakes, and normally had a disk shapeThe main ingredients are wheat flour, fat, eggs, sugar, milk powder, water flavouring and raising agents.

Cakes are generally made by using two different methods:

- Sugar batter method

- fat and sugar are creamed together, eggs are added in stages

- Flour batter method

- fat and flour are blended together. Eggs and sugar are whisked are whisked together and the mixture is blended into the flour-fat- mix in stages. Then the liquid are added in small amounts.

In continuous mixing systems the ingredients are given a preliminary mix and are then fed in a continuous even stream. But more often used is “all in” high speed mixing. All ingredients (except fruit) are added, and then fruit is added in short bursts.

The batter is put into oil- sprayed trays. After baking the cakes are removed from the tins and are cooled.

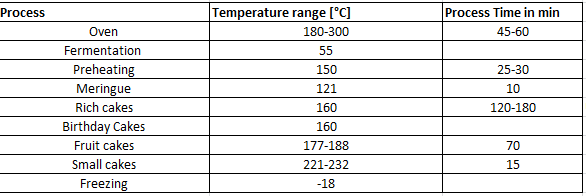

- 1.3 Temperature ranges and other parameters

Table 1: Temperature range of processes involved , Literature: UNIDO Technology Manual : Small scale cereal milling and bakery products.

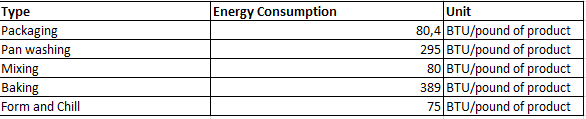

- 1.4 Benchmark data

Table 2: Energy Consumption in BTU per pound of product, Literature: Energy efficiency improvement and cost saving opportunitieas for the bakign industry.Eric Masanet,Peter Therkelsen and Ernst Worrell.

2. CHANGES IN PROCESSES:

- 2.1Changes in Energy Supply for unique Technology

- 2.1.1 Existing Heat/Cool Technology

- 2.1.2Changes in Distribution of the Heat/Cool System

- 2.1.3 Optimisation of the Heat/Cool System

- 2.1.3.1 Description of the Technology

- 2.1.3.2 Possible Energy Savings Reachable by those measures

- 2.1.3.3 Economic Evaluations

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about bread, biscuits & cakes production