Difference between revisions of "Molasses"

From Efficiency Finder

(Created page with "Back to EFFICENCY FINDER OF FOOD INDUSTRY <br> Back to Biobased products in sugar") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

<br> | <br> | ||

Back to [[Biobased products in sugar]] | Back to [[Biobased products in sugar]] | ||

| + | === Description === | ||

| + | Sugar beets contain some soluble non-sugar substances, 30 - 40 % of which are eliminated during purification of the juice with Ca2+ precipitable anions, pectins and proteins. The remainder is left in the juice and prevents the complete crystallisation of the sugar, leaving a final syrup, called molasses. This is the major single loss of sugar in the process. 10 - 18 % of the sugar content of the beet is in molasses. About 38 kg molasses per tonne of sugar beet is generated. Molasses is about 80 % solid material and 20 % water. (EC, 2006) | ||

| + | |||

| + | |||

| + | [[File:WasteWater.jpg]] | ||

| + | |||

| + | |||

| + | === Valorisation techniques === | ||

| + | * Animal feed | ||

| + | * Production of ethanol and bio-ethanol | ||

| + | * co-substrate for biogas production | ||

| + | |||

| + | === References === | ||

| + | * European Commission. 2006. Reference Document on Best Available Techniques in the Food, Drink and Milk industries | ||

| + | |||

| + | |||

| + | <br> | ||

| + | Back to [[Biobased products in sugar]] | ||

| + | <br> | ||

| + | Back to [[Subsection DA food|EFFICENCY FINDER OF FOOD INDUSTRY]] | ||

Latest revision as of 11:23, 19 November 2014

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Biobased products in sugar

Description

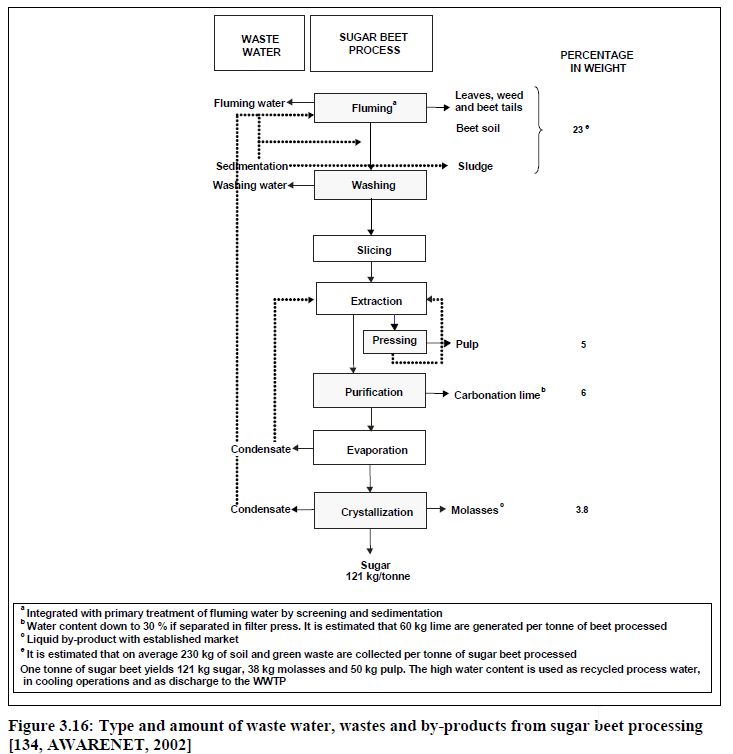

Sugar beets contain some soluble non-sugar substances, 30 - 40 % of which are eliminated during purification of the juice with Ca2+ precipitable anions, pectins and proteins. The remainder is left in the juice and prevents the complete crystallisation of the sugar, leaving a final syrup, called molasses. This is the major single loss of sugar in the process. 10 - 18 % of the sugar content of the beet is in molasses. About 38 kg molasses per tonne of sugar beet is generated. Molasses is about 80 % solid material and 20 % water. (EC, 2006)

Valorisation techniques

- Animal feed

- Production of ethanol and bio-ethanol

- co-substrate for biogas production

References

- European Commission. 2006. Reference Document on Best Available Techniques in the Food, Drink and Milk industries

Back to Biobased products in sugar

Back to EFFICENCY FINDER OF FOOD INDUSTRY