Difference between revisions of "Rinsing in metal industry"

From Efficiency Finder

(New page: Back to EFFICIENCY FINDER FOR METAL INDUSTRY *;Description of the process *;Rinsing flowsheet [[Image: Rinsing flows...) |

m (Changed protection level for "Rinsing in metal industry" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 48: | Line 48: | ||

*;Rinsing | *;Rinsing | ||

| − | |||

| − | |||

Latest revision as of 17:51, 13 February 2013

Back to EFFICIENCY FINDER FOR METAL INDUSTRY

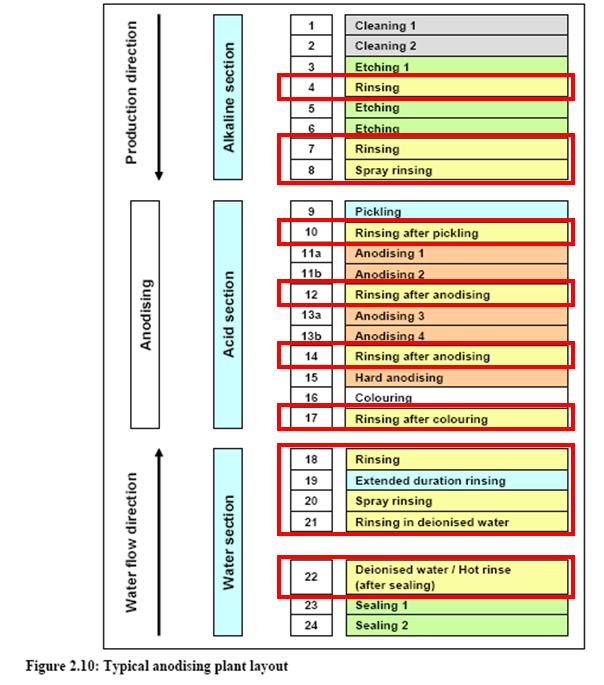

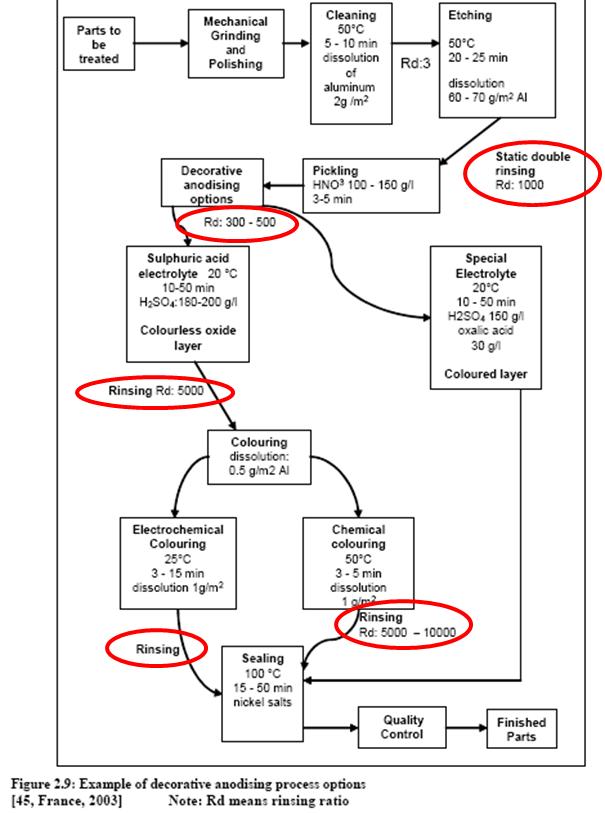

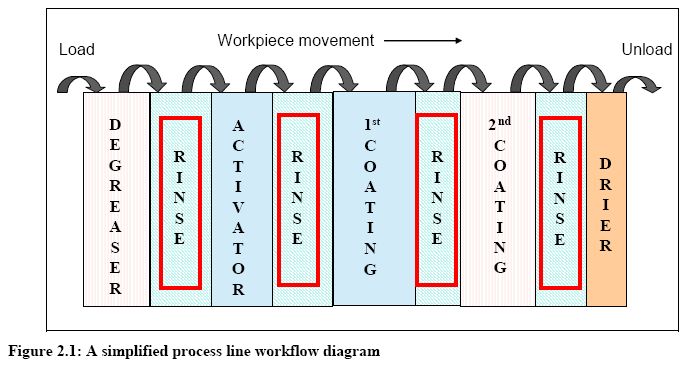

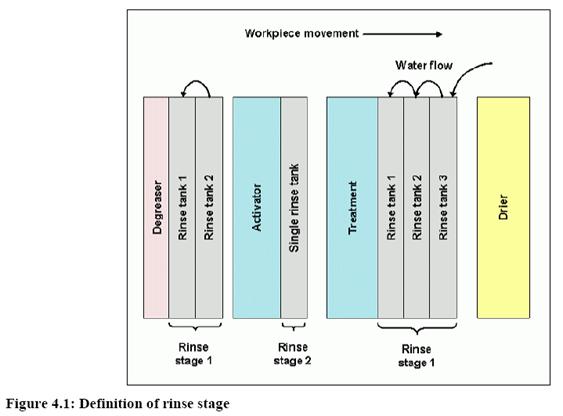

- Rinsing flowsheet

Literature: BAT for Surface Treatment of Metals & Plastics, 2006

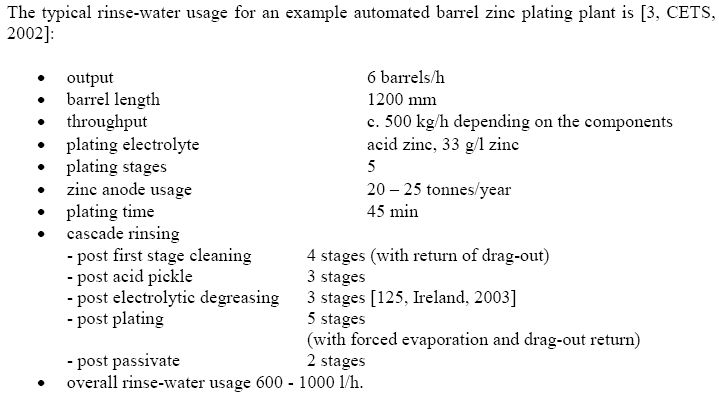

- Typical parameters of the process

| Process | Temperature [°C] | Heat transfer medium | Residence time | Chemicals | Concentration | Details | Literature |

| Alkalinde degreased steel rinsing | 70-85 | demineralized water | Chlorinated hydrocarbons (CHC), alcohols, terpenes, ketones, mineral spirits or hydrocarbons | BAT for the surface treatment of metals and plastics, August 2006 | |||

| Solvent rinsing from chromium electrolyted steel | 50-60 | demineralized water | |||||

| Alumium cleaning | 50 | 5-10 min |

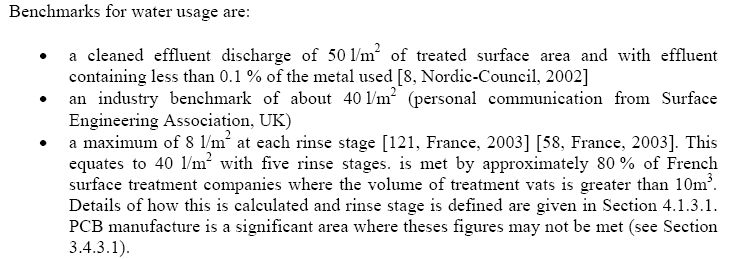

- Rinsing

Literature: BAT for the surface treatment of metals & plastics, 2006

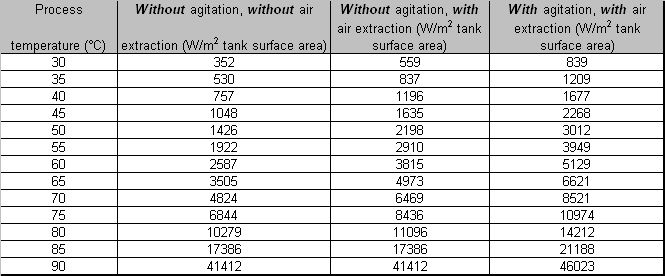

- Energy losses from the surface area of heated process solutions

LITERATURE: BAT for the Surface Treatment of Metals and Plastics, May 2005