Difference between revisions of "Wine"

m (Changed protection level for "Wine" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

|||

| (6 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

Back to [[Information about wine & beverages production]] | Back to [[Information about wine & beverages production]] | ||

| − | |||

| − | |||

| Line 12: | Line 10: | ||

;1. General Flowsheet of soft drink production: | ;1. General Flowsheet of soft drink production: | ||

| − | + | ||

;2. Description of techniques, methods and equipment: (BAT for Food, Drink and Milk Industries, June 2005) | ;2. Description of techniques, methods and equipment: (BAT for Food, Drink and Milk Industries, June 2005) | ||

| − | |||

| − | + | Wine is defined as the product that is recovered by partial or complete alcoholic fermentation of the fresh, treated grapes or the grapes must. If alcohol is added e.g. in the form of distillate of wine, dessert wine is obtained which contains alcohol between 15 and 22 % by volume. | |

| + | |||

| + | Champagne or sekt is produced when a second fermentation is carried out without the escape of the formed carbon dioxide. If carbon dioxide is artificially introduced the obtained product is simple sparkling wine or pearl wine. Wine, dessert wines, pearl wines and sparkling wines can be further processed to vinous beverages. These kinds of beverages have a proportion of wine in excess of 50%. The best known products of this category are the aromatized wines e.g. vermouth. | ||

| + | If fruits or other sugar- or starch- containing raw materials are used in processing, the end product is not wine within the meaning of the pertinent wine legislation but a product similar to wine is obtained. Examples are fruit wines; the main representative product of this group is cider. | ||

| + | |||

| + | [[Image:wine.JPG]] | ||

| + | |||

| + | Figure 1: Different types of table wine | ||

| Line 48: | Line 52: | ||

Critical issues concerning the possible solar integration | Critical issues concerning the possible solar integration | ||

| + | |||

| + | ''Reference: Caballero, B., Finglas, P., Trugo, L.: Encyclopedia of food science and nutrition, Academic Pr. Inc., 2003, pages 6189-6202'' | ||

Latest revision as of 13:34, 20 February 2013

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about wine & beverages production

1. GENERAL DESCRIPTION:

- 1. General Flowsheet of soft drink production

- 2. Description of techniques, methods and equipment

- (BAT for Food, Drink and Milk Industries, June 2005)

Wine is defined as the product that is recovered by partial or complete alcoholic fermentation of the fresh, treated grapes or the grapes must. If alcohol is added e.g. in the form of distillate of wine, dessert wine is obtained which contains alcohol between 15 and 22 % by volume.

Champagne or sekt is produced when a second fermentation is carried out without the escape of the formed carbon dioxide. If carbon dioxide is artificially introduced the obtained product is simple sparkling wine or pearl wine. Wine, dessert wines, pearl wines and sparkling wines can be further processed to vinous beverages. These kinds of beverages have a proportion of wine in excess of 50%. The best known products of this category are the aromatized wines e.g. vermouth. If fruits or other sugar- or starch- containing raw materials are used in processing, the end product is not wine within the meaning of the pertinent wine legislation but a product similar to wine is obtained. Examples are fruit wines; the main representative product of this group is cider.

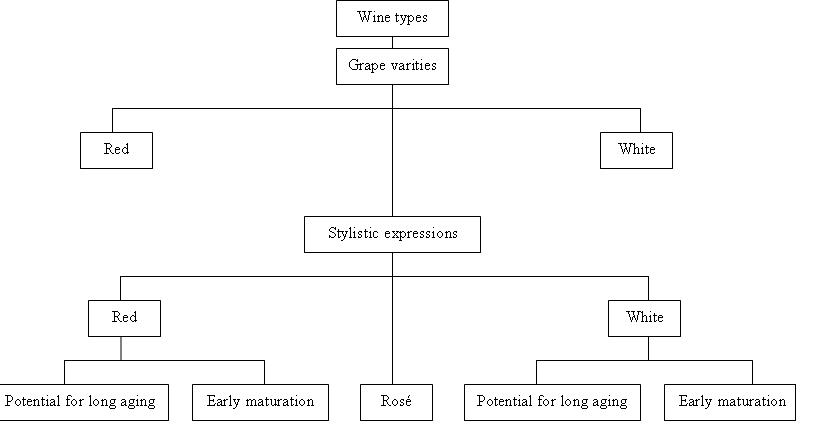

Figure 1: Different types of table wine

- 3. Temperature ranges and other parameters (table)

No information is available.

- 4. Benchmark data

No information is available.

2. NEW TECHNOLOGIES:

- a) Changes in the process

- No information is available.

- b) Changes in the energy distribution system

- No information is available.

- c) Changes in the heat supply system

- No information is available.

3. SOLAR SYSTEMS INTEGRATION:

Critical issues concerning the possible solar integration

Reference: Caballero, B., Finglas, P., Trugo, L.: Encyclopedia of food science and nutrition, Academic Pr. Inc., 2003, pages 6189-6202