Cooked ham

Back to EFFICENCY FINDER OF FOOD INDUSTRY

Back to Information about meat production

1. GENERAL DESCRIPTION:

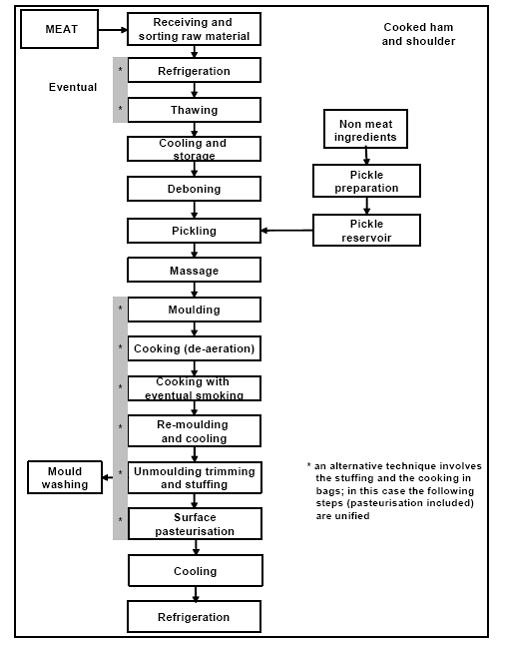

- 1. General Flowsheet of cooked ham production

- (BAT in the Food, Drink and Milk Industries, June 2005)

The preservation of meat by cooking is used for several products, such as sausages, dressed pork and mortadella. The general process is presented below:

Figure 1: Canned meat production.

Literature: BAT in Food, Drink and Milk Industries, June 2005

- 2. Description of techniques, methods and equipment

- (BAT in the Food, Drink and Milk Industries, June 2005)

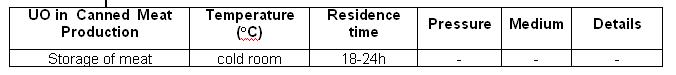

First the material is received and then sorted. Thawing in this case is similar to the canned meat process. In the production of whole hams or shoulders, the meat is held in a cold room for 18-24h, to achieve a uniform temperature inside the meat. Losses can occur due to the dripping of meat juice. The material is then cutted, pickled and homogenized. After moulding, the product is de-aerated and cooked and/or smoked. The cooking can be carried out in a water bath, shower, steam or hot air ovens. Water bath ovens are used for whole meat products. However, a lot of water and energy is needed, major weight loss and water pollution occurs due to the leaching of meat, but the heat transfer is homogeneous. Shower ovens provide good heating uniformity and use less water and energy. Steam ovens provide a moist humid heat, where food is cooked in a gentle environment to retain its flavour and moisture. Air ovens require humidity control. Ham may be also re-moulded and then cooled. Moulds are removed and cleaned. Hams and shoulders are normally trimmed and may be sprinkled with flour to improve the look. Packing is normally carried out under vacuum.

- 3. Temperature ranges and other parameters (table)

- (BAT in the Food, Drink and Milk Industries, June 2005)

- 4. Benchmark data (from BAT or from other sources) such as

- (BAT in the Food, Drink and Milk Industries, June 2005)

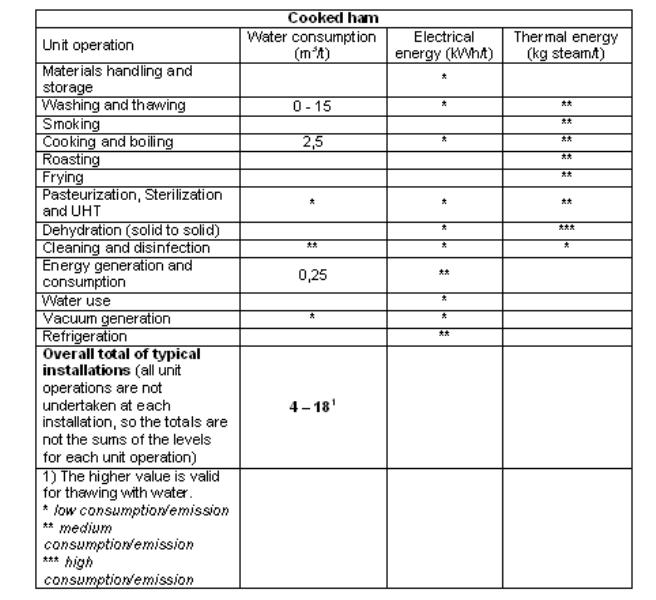

The following table summarizes the reported consumption and emission levels expressed per tonne of finished product in the Italian meat industry for cooked ham manufacturing:

Table 1: Consumption and emission levels for cooked ham manufacturing in Italy

2. NEW TECHNOLOGIES:

- a) Changes in the process

No information is available.

- b) Changes in the energy distribution system

No information is available.

- c) Changes in the heat supply system

No information is available.